YSI2700 communication driver is the driver to communicate with Bioanalytical product analyzer controller.

1. Read settings

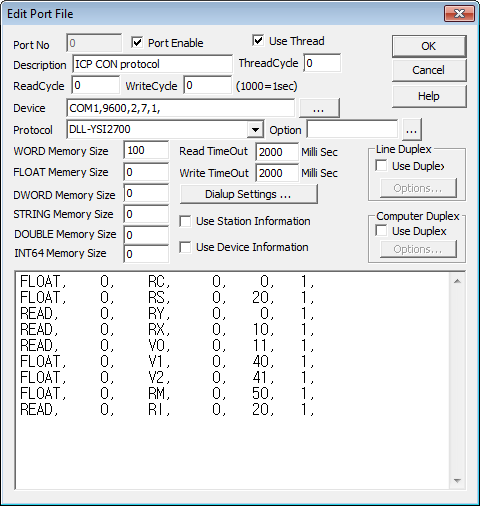

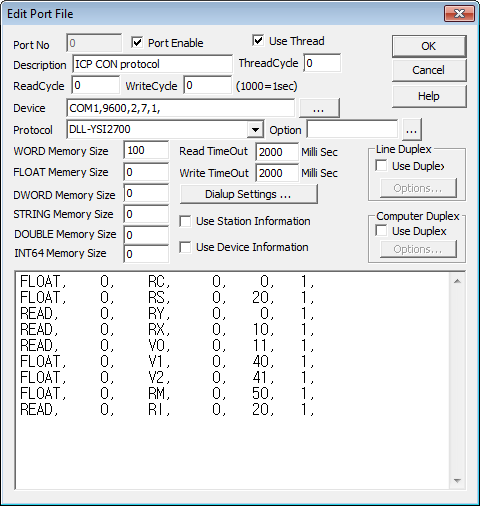

<Figure 1> is read setting example of YSI2700 communication driver.

|

| <Figure 1> Read setting example of YSI2700 communication driver |

| READ | Station | Device Type | Address (Don't care) |

Save Start Address |

Read Size (Fixed) |

| FLOAT, | 0, | RC, | 0, | 0, | 1, |

| FLOAT, | 0, | RS, | 0, | 20, | 1, |

| READ, | 0, | RY, | 0, | 0, | 1, |

| READ, | 0, | RX, | 0, | 10, | 1, |

| READ, | 0, | V0, | 0, | 11, | 1, |

| FLOAT, | 0, | V1, | 0, | 40, | 1, |

| FLOAT, | 0, | V2, | 0, | 41, | 1, |

| FLOAT, | 0, | RM, | 0, | 50, | 1, |

| READ, | 0, | RI, | 0, | 20, | 1, |

1) Station : Don't care.

2) Device Type : RC, RS, RS1 ~ RS9, RY, RX, V0, V1, V2, RM, RI etc.

3) Save Start Address : Position of scan memory to save the reade value.

4) Read Size : Fixed by each device. (Refer to <Table 1> ~ <Table 4>)

| Data Saving Address | Contents | Remarks |

| Save location+0 | Communication error state | Normal - 0, Error 1 ~ 9 |

| " + 1 ~ 3 | data report Hour, Min, Sec |

|

| " + 4 ~ 6 | data report Month, Day, Year | Position of year and day is changed according to settings |

| " + 7 | Temperature | Float |

| " + 8 | probe chemistry assignment | 0 - NONE, 0bit - DEC, 1bit _ LAC, ... 10bit - CHOL |

| " + 9 | sample or calibration result | Float |

| " + 10 | sample or calibration unit | 0 - NONE, 0bit - mmol/L, 1bit _ mg/L 2bit _ g/L 3bit _ % 4bit – nA |

| " + 11 | error code |

|

| <Table 1> Save location and contents of YSI2700 according to device type such as RC, RS or R1~ R9 | ||

| Data Saving Address | Contents | Remarks |

| Save location+0 | Communication mode | 0 - reporting mode, 1- remode control, 2 - none |

| " + 1 | sample status result | 0 - result not sent, 1 - no unsent result |

| " + 2 | calibration status result | 0 - result not sent, 1 - no unsent result |

| " + 3 | machine status | 0bit - Idle in run, 1bit - Processing sample, 2bit - Processing calibration, 3bit - Processing auto cal, 4bit - Processing manual ample, 5bit - Processing precal cycle, 6bit - Processing monitor cycle, 7bit - Processing postcal cycle, 8bit - error abort, 9bit - stabilizing baseline, 10bit - stabilizing calibration, 11bit - stabilizing motors, 12bit - aborting run mode, 13bit - in run mode, 14bit - in standby mode, 15bit - in main menu, 0bit - Idle, |

| " + 4 | remote control status | 1bit - sam command, 2bit - cal command, 3bit - unknown |

| <Table 2> Save location of YSI2700 RY type | ||

| Data Saving Address | Contents | Remarks |

| Save location+0 | Communication error state | Normal - 0, Error 1 ~ 9 |

| " + 1 ~ 3 | data report Hour, Min, Sec |

|

| " + 4 ~ 6 | data report Month, Day, Year | Position of year and day is changed according to settings |

| " + 7 | Don't care |

|

| " + 8 | probe chemistry assignment | 0 - NONE, 0bit - DEC, 1bit _ LAC, ... 10bit - CHOL |

| " + 9 | sample or calibration result | Float |

| " + 10 | sample or calibration unit | 0 - NONE, 0bit - mmol/L, 1bit _ mg/L 2bit _ g/L 3bit _ % 4bit - nA |

| " + 11 | calibration end time | 15 ~ 90 sec |

| " + 12 | calibration station no | 1 ~ 5 |

| <Table 3> Save location of YSI2700 RM type | ||

| Data Saving Address | Contents | Remarks |

| Save location+0 | Communication error state | Normal - 0, Error 1 ~ 9 |

| " + 1 | radix |

|

| " + 2 | date format |

|

| " + 3 | bottle level |

|

| " + 4 | smaple size |

|

| " + 5 | sample station |

|

| " + 6 | cal method |

|

| " + 7 | error flag |

|

| " + 8 | temperature shift |

|

| " + 9 | time interval |

|

| " + 10 | number of sample between |

|

| " + 11 | cal shift allowed |

|

| " + 12 | autostandby time |

|

| " + 13 | default starting turntable pos |

|

| " + 14 | default starting turntable test tube loads |

|

| " + 15 | turntable fludi detection flag |

|

| " + 16 | monitor station no |

|

| " + 17 | monitor time interval |

|

| " + 18 | monitor precal time |

|

| " + 19 | monitor postcal time |

|

| " + 20 | monitor pump purge time |

|

| <Table 4> Save location of YSI2700 RI type | ||

Digital Write

Digital write setting items are as follows:

1) PORT Connected port number 0 ~ 255

2) Station Don't care

3) Address Don't care Possible to designate the print state address

4) Extra 1 Device type PC, PS1 ~ PS5, TR0, TR1, TP0, TP1, PA, TN0, TN1 etc

Ex1) Remote control state value of YSI2700 can be controlled(ON/OFF), when Extra 1 is set as TR.

Analog Write

It is function to output the value to DPM controller

Analog write setting items are as follows:

1) PORT Connected port number 0 ~ 255

2) Station Don't care

3) Address Don't care Possible to designate the print state address

4) Extra 1 Device type PC, PS1 ~ PS5, TR0, TR1, TP0, TP1, MP, MT, MR, MO, MS, PA, TN0, TN1 etc

Ex1) Pump purge time of YSI2700 can be controlled, when Extra 1 is set as MP.