XGT Loader is driver to communicate with general-purpose PLC XGT series of LS Industrial System.

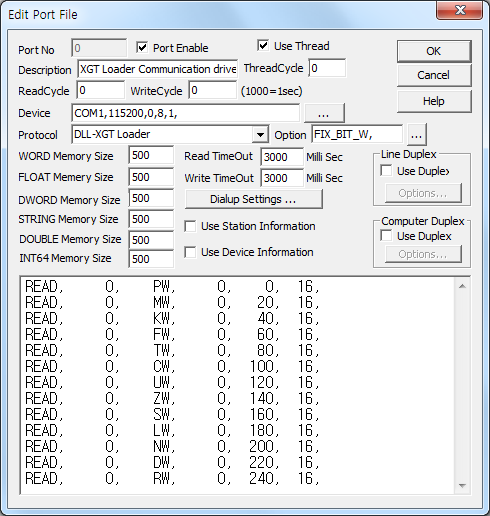

<Figure 1> is read setting example of XGT Loader communication driver.

|

| <Figure 1> Read setting example of XGT Loader driver |

Device Setting of <Figure 1> are input, Com Port(COM1), Com Baud(115200), Parity Bit(0), Data Bit(8), Stop Bit(1).

Also, you can set whether to fix of 'Bit Write addressing Error'( 0 : don't fix, FIX_BIT_W : fix, default = 0) by using option part (separated by commas each parameter).

Note) Communication speed of XGT Loader is fixed to 38400 or 115200, and parity etc are fixed to 0, 8, 1.

XGT Loader driver read schedule

Read schedule setting parameters are as follows :

1) Station : Don't care.

2) Device Type : Input the PLC device such as P, M, K, F, T, C, U, Z, S, L, N, D, R, ZR. (Refer to <Table 1>)

Input the unit to read next to device type such as X(10 bit), W(Word), D(Double Word), F(Float Lo Hi), F2(Float Hi Lo). (Default = W)

3) Read Start Address : Start address to read at designated device.

4) Save Start Address for Communication Server : Saving start address of Communication Server.

5) Read Size : Data size to read at a time. (Max 127 WORD)

Read schedule example)

READ, 0, PW, 0, 0, 16,

READ, 0, MW, 0, 20, 16,

READ, 0, KW, 0, 40, 16,

READ, 0, FW, 0, 60, 16,

READ, 0, TW, 0, 80, 16,

READ, 0, CW, 0, 100, 16,

READ, 0, UW, 0, 120, 16,

READ, 0, ZW, 0, 140, 16,

READ, 0, SW, 0, 160, 16,

READ, 0, LW, 0, 180, 16,

READ, 0, NW, 0, 200, 16,

READ, 0, DW, 0, 220, 16,

READ, 0, RW, 0, 240, 16,

<Table 1> is PLC device type and size to be used at XGT Loader communication driver.

Device Type |

Range | Size | Remarks |

P |

P0 ~ P2047 | 2048 Word |

|

M |

M0 ~ M2047 | 2048 Word |

|

K |

K0 ~ K2047 | 2048 Word |

|

F |

F0 ~ F1023 | 2048 Word |

Read only |

| F1024 ~ F2047 |

|

||

T |

T0 ~ T2047 | 2048 Word |

|

C |

C0 ~ C2047 | 2048 Word |

|

U |

U00.00 ~ U7F.31 | 4096 Word |

|

Z |

Z0 ~ Z127 | 128 Word |

|

S |

S0 ~ S127 | 128 Word |

|

L |

L0 ~ L11263 | 11264 Word |

|

N |

N0 ~ N21503 | 21504 Word |

|

D |

D0 ~ D32767 | 32768 Word |

CPUH |

| D0 ~ D19999 | 20000 Word |

CPUS |

|

R |

R0 ~ R32767 | 32768 Word |

|

ZR |

ZR0 ~ ZR65535 | 65536 Word |

In case of CPUH |

| <Table 1> PLC device type and size to be used at XGT Loader communication driver | |||

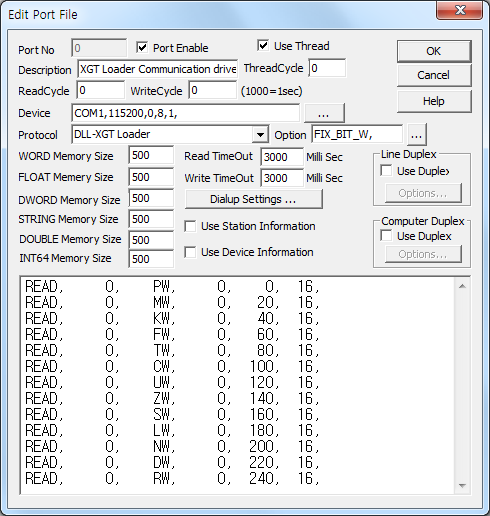

If you click the icon

![]() in protocol option part, you

can see the dialog box such as <Figure 2>. you can also set read

schedule by using this part.

in protocol option part, you

can see the dialog box such as <Figure 2>. you can also set read

schedule by using this part.

|

| <Figure 2> Example of XGT Loader communication driver's Option dialog box |

You can set read schedule by using

![]() ,

,

![]() ,

,

![]() button and

listbox of <Figure 2>.

button and

listbox of <Figure 2>.

Whether to fix of 'Bit Write addressing Error' can set by using of Protocol Option part in <Figure 2>.

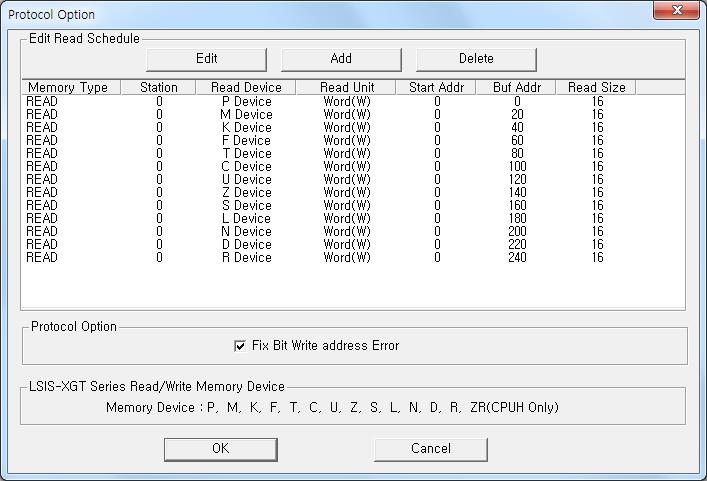

|

| <Figure 3> Example of XGT Loader communication driver's read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialog box of <Figure 2>, dialog box of <Figure 3> is shown.

You can change value of specified device of XGT PLC by using the write command.

Digital Write

Digital write setting parameters are as follows :

1) Port : Connected Port no. (It is not COM number)

2) Station : Don't care.

3) Address : Decimal output address as bit unit of device to output.

4) Extra1 : Input the PLC device such as P, M, K, F, T, C, U, Z, S, L, N, D, R, ZR. (Refer to <Table 1>)

5) Extra2 : Don't care.

Write example 1)

PORT : 0 STATION : 0 ADDRESS : 0000 EXTRA1 : MX EXTRA2 : 0

If you set as above and output the digital value, you can control(ON/OFF) value for MX0000 address of XGT PLC which connected to no.0 port.

Write example 2)

PORT : 0 STATION : 0 ADDRESS : 0052 EXTRA1 : MX EXTRA2 : 0

If you set as above and output the digital value, you can control(ON/OFF) value for MX0052 address of XGT PLC which connected to no.0 port.

Write example 3)

PORT : 0 STATION : 0 ADDRESS : 0125 EXTRA1 : DX EXTRA2 : 0

If you set as above and output the digital value, you can control(ON/OFF) value for DX0125 address of XGT PLC which connected to no.0 port.

Analog Write

Analog write setting parameters are as follows :

1) Port : Connected Port no. (It is not COM number)

2) Station : Don't care.

3) Address : Decimal output address for Word(W, etc)/DoubleWord(D)/Float(F, F2) unit of device to output.

4) Extra1 : Input the device type such as P, M, K, F, T, C, U, Z, S, L, N, D, R, ZR. (Refer to <Table 1>)

Input the data unit(Default = W) such as W(Word), D(DoubleWord), F(Float Lo Hi), F2(Float Hi Lo), to beside device type.

5) Extra2 : Don't care.

Write example 1)

PORT : 0 STATION : 0 ADDRESS : 0000 EXTRA1 : M EXTRA2 : 0

If you set as above and output the analog value, you can change the Word value for MW0000 address of XGT PLC which connected to no.0 port.

Write example 2)

PORT : 0 STATION : 0 ADDRESS : 0012 EXTRA1 : MW EXTRA2 : 0

If you set as above and output the analog value, you can change the Word value for MW0012 address of XGT PLC which connected to no.0 port.

Write example 3)

PORT : 0 STATION : 0 ADDRESS : 0037 EXTRA1 : DW EXTRA2 : 0

If you set as above and output the analog value, you can change the Word value for DW0037 address of XGT PLC which connected to no.0 port.

Write example 4)

PORT : 0 STATION : 0 ADDRESS : 0063 EXTRA1 : DD EXTRA2 : 0

If you set as above and output the analog value, you can change the DoubleWord value for DD0063 address of XGT PLC which connected to no.0 port.

Write example 5)

PORT : 0 STATION : 0 ADDRESS : 0072 EXTRA1 : DF EXTRA2 : 0

If you set as above and output the analog value, you can change the DoubleWord value as Float Lo, Hi order(IEEE form) for DD0063 address of XGT PLC which connected to no.0 port.

Write example 6)

PORT : 0 STATION : 0 ADDRESS : 0005 EXTRA1 : DF2 EXTRA2 : 0

If you set as above and output the analog value, you can change the DoubleWord value as Float Hi, Lo order(IEEE form) for DD0002 address of XGT PLC which connected to no.0 port.

Connect serial communication cable for Loader terminal of XGT PLC and basic power as follows.

Communication cable connection

Connect general RS-232C cable to serial communication cable for Loader terminal of XGT PLC.

<Figure 4> is appearance of XGT PLC.

|

| <Figure 4> Appearance of XGT PLC |

Basic power connection

Connect basic power of 110 ~ 240 V AC to L, N terminal of XGT PLC such as <Figure 4>.