UFL-20 Flow Meter Series is driver to communicate with Flow Meter device of Tokimec Inc. in Japan.

Reference) UFL-20 Flow Meter Series RS-232C communication enable to communicate in case of using RS-232C of device.

(It enable to communicate when letter of RS2 is displayed at upper right of LCD screen)

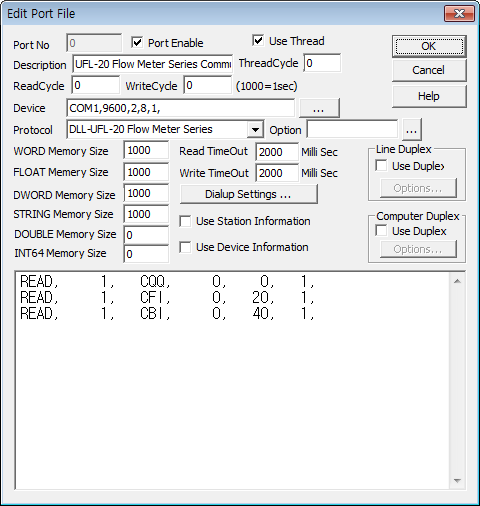

<Figure 1> is read setting example of UFL-20 Flow Meter Series communication driver.

|

| <Figure 1> Read setting example of UFL-20 Flow Meter Series driver |

Device Setting of <Figure 1> are input, Com Port(COM1), Com Baud(9600), Parity Bit(2), Data Bit(8), Stop Bit(1).

Reference) You can set Com Baud(1200, 2400, 4800, 9600) of UFL-20 Flow Meter Series at device and Parity Bit, etc are fixed to 2, 8, 1.

Read schedule of UFL-20 Flow Meter Series driver

Read schedule setting parameters are as follows :

1) Station : Don't care.

2) Data Type : CQQ : Reading Flow Rate or Volume speed,

CFI/CBI : Reading FW/BW Integrated Flow Rate,

CID : Reading setting data of Input Menu,

CCD : Reading setting data of Check Menu,

BASICDAT : Reviewing of Basic Data,

CHECK : Self Check,

ERR : Reading Error status,

3) Read Start Address : Don't care.

4) Save Start Address for Communication Server : Saving start address for Communication Server.

5) Read Size : Fixed to 1. ( Fixed according to data type to read, refer to <Table 1> )

Read schedule example)

READ, 1, CQQ, 0, 0, 1,

READ, 1, CFI, 0, 20, 1,

READ, 1, CBI, 0, 40, 1,

<Table 1> is data type to read and contents to be used at UFL-20 Flow Meter Series communication driver.

| Data Type | Contents | Save address & Contents of read data |

Read conditions |

| CQQ or Etc | Reading Flow Rate or Volume speed | Save addr + 0 : Flow Rate value, Save addr + 1 : Fixed random value, Save addr + 2 : Flow Rate unit(Value between 0 and 14, refer to <Table 2>), Save addr + 3 : FS(When Full Scale Over = 1, Etc = 0), Save addr + 4 : AGC(AGC is Turned On = 1, Etc = 0), Save addr + 5 : LOW(Output is Low Range = 1, Etc = 0), Save addr + 6 : ROFF(ROFF status = 1, Etc = 0), Save addr + 7 : ABN(When use ABN function = 1, Etc = 0), Save addr + 8 : OVER(Upper/Lower Limit Alarm = 1, Etc = 0), Save addr + 9 : WAGC(AGC Warning status = 1, Etc = 0), Save addr + 10 : Reserved(Don't care), Save addr + 11 : LB(When Memory battery is less than setting value = 1, Etc = 0), Save addr + 12 : ARM(ARM = 1, Etc = 0), Save addr + 13 : ITG(Integration Mode = 1, Etc = 0) |

In case of Measurement(RUN) Status |

| CFI/CBI | Reading FW/BW Integrated Flow Rate | Save addr + 0 : FW/BW Integrated value, Save addr + 1 : Integrated unit(Value between 0 and 23, refer to <Table 3>), Save addr + 2 : FS(In case of Full Scale Over = 1, Etc = 0), Save addr + 3 : AGC(AGC is Turned On = 1, Etc = 0), Save addr + 4 : LOW(Output is Low Range = 1, Etc = 0), Save addr + 5 : ROFF(ROFF status = 1, Etc = 0), Save addr + 6 : ABN(When use ABN function = 1, Etc = 0), Save addr + 7 : OVER(Upper/Lower Limit Alarm = 1, Etc = 0), Save addr + 8 : WAGC(AGC Warning status = 1, Etc = 0), Save addr + 9 : Reserved(Don't care), Save addr + 10 : LB(When Memory battery is less than setting value = 1, Etc = 0), Save addr + 11 : ARM(ARM = 1, Etc = 0), Save addr + 12 : ITG(Integration Mode = 1, Etc = 0) |

|

| CID | Reading setting data of Input Menu | Save addr + 0 : Function display(Flow or Velocity), Save addr + 1 : Multiplier (E=3 etc), Save addr + 2 : Unit in case of Flow Rate, Save addr + 3 : Density, Save addr + 4 : A-OUT Type, Save addr + 5 : FW Max Flow High Range, Save addr + 6 : FW Max Flow Low Range, Save addr + 7 : BW Max Flow High Range, Save addr + 8 : BW Max Flow Low Range, Save addr + 9 : Classfy(FW/BW or HI/LO), Save addr + 10 : Auto HI/LO On/Off status, Save addr + 11 : Limit ON/OFF status, Save addr + 12 : FW Upper value, Save addr + 13 : FW Lower value, Save addr + 14 : BW Upper value, Save addr + 15 : W Upper value, Save addr + 16 : ROFF ON/OFF status, Save addr + 17 : FW/BW Ope. ON/OFF status, Save addr + 18 : FW Zero Shift value, Save addr + 19 : FW Span Corr. value, Save addr + 20 : FW Zero Cut value, Save addr + 21 : BW Zero Shift value, Save addr + 22 : BW Span Corr. value, Save addr + 23 : BW Zero Cut value, Save addr + 24 : ROFF Operation(100%, HOLD, 0%), Save addr + 25 : Time(0 ~ 120s), Save addr + 26 : FW Integ. Unit(Refer to <Table 3>), Save addr + 27 : BW Integ. Unit(Refer to <Table 3>), Save addr + 28 : Stop Mode(Manual, Timer), Save addr + 29 : Timer(hhmmss), Save addr + 30 : BCD Out Interval time(Sec), Save addr + 31 : Baud Rate(9600, 4800, 2400, 1200), Save addr + 32 : Remote HI/LO(Contact, RS232C) |

In case of COMMU/HOLD(STOP) status

Store read value to STRING memory as it is = Store behind number to WORD/DWORD/FLOAT memory (In case of not number, save 0) |

| CCD | Reading setting data of Check Menu | Save addr + 0 : A-Out(FINISH, CH1, CH2), Save addr + 1 ~ 2 : CH1, CH2 setting value(%), Save addr + 3 : Range(FINISH, HI, LO), Save addr + 4 : Multi Path(FINISH, PATH1 ~ 4), Save addr + 5 : Gain(Manual, Auto), Save addr + 6 ~ 9 : Gain 1 ~ 4U Setting value, Save addr + 10 ~ 13 : Gain 1 ~ 4D Setting value, Save addr + 14 : AGC(OFF, ON), Save addr + 15 ~ 18 : CT0(Design) 1 ~ 4 value, Save addr + 19 ~ 22 : T0(Real) 1 ~ 4 value, Save addr + 23 ~ 26 : Delta 1 ~ 4 value, Save addr + 27 : Reynolds Number value, Save addr + 28 : C0(Real) value |

|

| BASICDAT | Reviewing of Basic Data | Save addr + 0 ~ 3 : CT0(Design) 1 ~ 4 value, Save addr + 4 ~ 7 : T0(Real) 1 ~ 4 value, Save addr + 8 ~ 11 : Delta 1 ~ 4 value, Save addr + 12 : Reynolds Number value, Save addr + 13 : C0(Real) value |

|

| CHECK | CHECK | Save addr + 0 : ROM Administration Number, Save addr + 1 : ROM OK or NG, Save addr + 2 : RAM OK or NG, Save addr + 3 :,I/O OK or NG, Save addr + 4 : COUNTER OK or NG, Save addr + 5 : TX OK or NG, Save addr + 6 : RX OK or NG, Save addr + 7 : Counter Normal = Blank, Abnormal = Number, Save addr + 8 : Counter Normal = Blank, Abnormal = Number |

|

| ERR | Reading Error status | Save addr + 0 : wCOM display, Save addr + 1 : COMMAND, Save addr + 2 : DATA, Save addr + 3 : ITG, Save addr + 4 : KEY |

In case of Measurement(RUN), COMMU/HOLD(STOP) status(Always) |

| <Table 1> Data type to read and contents of UFL-20 Flow Meter Series communication driver | |||

Unit |

Save Value |

M3/D |

0 |

M3/h |

1 |

M3/m |

2 |

m3/s |

3 |

L/h |

4 |

L/m |

5 |

L/s |

6 |

t/D |

7 |

t/h |

8 |

t/m |

9 |

t/s |

10 |

kg/h |

11 |

kg/m |

12 |

kg/s |

13 |

Etc |

14 |

| <Table 2> Flow Rate unit and save value of UFL-20 Flow Meter Series communication driver | |

Unit |

Save Value |

NONE |

0 |

x10000m3 |

1 |

x1000m3 |

2 |

x100m3 |

3 |

x10m3 |

4 |

x1m3 |

5 |

x100L |

6 |

x10L |

7 |

x1L |

8 |

x100mL |

9 |

x10mL |

10 |

x100kt |

11 |

x10kt |

12 |

x1kt |

13 |

x100t |

14 |

x10t |

15 |

x1t |

16 |

x100kg |

17 |

x10kg |

18 |

x1kg |

19 |

x100g |

20 |

x10g |

21 |

x1g |

22 |

Etc |

23 |

| <Table 3> Integrated unit and save value of UFL-20 Flow Meter Series communication driver | |

Notice) Read value of UFL-20 Flow Meter Series driver is saved at same save location of WORD/FLOAT/DWORD/STRING memory, and save value is different according to memory type.

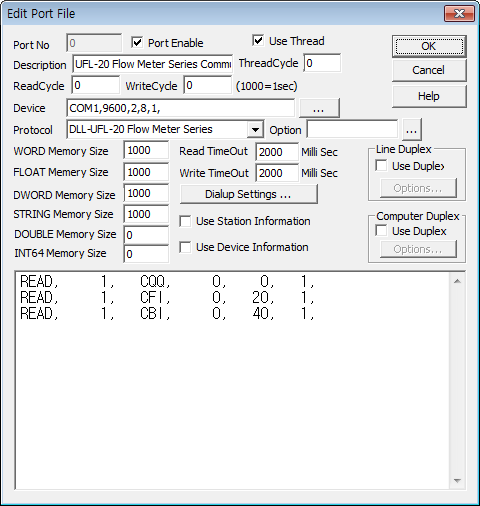

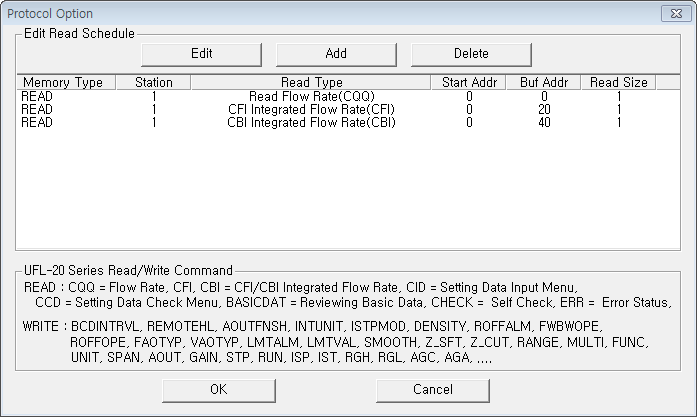

If you click the icon ![]() in protocol option

part, you can see the dialog box such as <Figure 2>. You can also set read

schedule by using this part.

in protocol option

part, you can see the dialog box such as <Figure 2>. You can also set read

schedule by using this part.

|

| <Figure 2> UFL-20 Flow Meter Series communication driver's Option dialog box |

You can set read schedule by using ![]() ,

, ![]() ,

, ![]() button and listbox of

<Figure 2>.

button and listbox of

<Figure 2>.

|

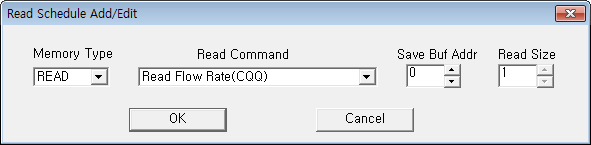

| <Figure 3> UFL-20 Flow Meter Series communication driver's read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialog box of <Figure 2>, dialog box of <Figure 3> is shown.

You can set UFL-20 Flow Meter Series device by using write settings.

Digital Write

Digital write and analog write have the same setting parameters except output value.

Analog Write

Analog write setting parameters are as follows :

1) Port : Connected Port number. (Not COM number)

2) Station : Don't care.

3) Address : In case of write command – 0 = Enter command, 1, Etc = Enter the command and command parameter,

In case of read command – Don't care.

4) Extra1 : Write/Read command,

BCDINTRVL : Setting of Renewal Cycle of BCD Output,

REMOTEHL : Selection of Range Changing Method,

AOUTFNSH : Finishing of A-Out Check,

INTUNIT : Selection of Integrated Unit,

ISTPMOD : Selection of Stopping Method of Integration,

DENSITY : Setting of Fluid Density,

ROFFALM : On/Off Selection of ROFF Alarm Output,

FWBWOPE : On/Off Selecting of Forward/Backward Change Confirmation,

ROFFOPE : Selecting of R-OFF Operation,

FAOTYP : Selection of Analog Output Type During Flow Meter,

VAOTYP : Selection of Analog Output Type During Velocity Meter,

LMTALM : On/Off Selection of High/Low Limit Alarm,

LMTVAL : Setting of High/Low Limit Alarm Value,

SMOOTH : Setting of Dumping Time for Smoothing Filter,

Z_SFT : Setting of Zero Shift,

Z_CUT : Setting of Zero Cut,

RANGE : Setting of Range Check,

MULTI : Setting of Measuring Path Fixing,

FUNC : Switching to Flow Meter or Velocity Meter,

UNIT : Selection of Flow Rate Unit,

SPAN : Setting of Span Adjustment,

AOUT : Setting of A-OUT Check,

GAIN : Setting of Manual Gain,

STP : Stopping Measurement,

RUN : Starting Measurement,

ISP : Stopping Integration,

IST : Starting Integration,

RGH : Changing Range to High,

RGL : Changing Range to Low,

AGC : On/Off Selection of AGC,

AGA : Starting Automatic Gain Adjustment,

CQQ, CFI/CBI, CID, CCD, BASICDAT, CHECK , ERR : Read command(Refer to <Table 1>),

5) Extra2 : Enter setting value according to write type. (Refer to <Table 4>)

<Table 4> is description for output type and output parameter, etc which are used at UFL-20 Flow Meter Series communication driver, <Table 5> is input method for downloaded data.

| Command Type(Extra1) | Address | Extra2 |

Output/Download Data |

Contents |

Condition |

| BCDINTRVL | 0 = Command Input, 1, Etc = Enter the command and command parameter |

Don't care |

0 ~ 99 |

Setting of Renewal Cycle of BCD Output |

In case of COMMU/HOLD(STOP) status |

| REMOTEHL |

|

0 = Contact, 1 = RS232C |

Selection of Range Changing Method |

||

| AOUTFNSH |

|

Don't care |

Finishing of A-Out Check |

||

| INTUNIT |

FW Integration unit value between 0 and 22 (Refer to <Table 3>) |

BW Integration unit value between 0 and 22 (Refer to <Table 3>) |

Selection of Integrated Unit |

||

| ISTPMOD | 0 = Manual, 1 = Timer |

In case of Extra2 = 1, Hhmmss setting value (hh = 0 ~ 99 hour, mm/ss = 0 ~ 59 min/sec) |

Selection of Stopping Method of Integration |

||

| DENSITY | Don't care |

Density setting value between 0.1 and 9.0 |

Setting of Fluid Density |

||

| ROFFALM | 0 = OFF, 1 = ON |

On/Off Selection of ROFF Alarm Output |

|||

| FWBWOPE | 0 = OFF, 1 = ON |

On/Off Selecting of Forward/Backward Change Confirmation |

|||

| ROFFOPE | 0 = Z(0 %), 1 = H(Hold), 2 = F(100 %) |

Selecting of R-OFF Operation |

|||

| FAOTYP | File number between 0 and 999, WorkDirectory\SCAN\ Enter the data%03d_%03d.ini command (Front %03d : PORT number, Back %03d : Extra2 value) |

Don't care

Enter seven setting parameter by referring to <Table 6> |

Selection of Analog Output Type During Flow Meter |

||

| VAOTYP | Selection of Analog Output Type During Velocity Meter |

||||

| LMTALM | Don't care |

0 = OFF, 1 = ON |

On/Off Selection of High/Low Limit Alarm |

||

| LMTVAL | File number between 0 and 999, WorkDirectory\SCAN\ Enter the data%03d_%03d.ini command (Front %03d : PORT number, Back %03d : Extra2 value) |

Don't care

Four setting parameters are entered as FW Upper/Lower(0.000 ~ 9999.0), BW Upper/Lower(0.000 ~ -9999.0), in order |

Setting of High/Low Limit Alarm Value |

||

| SMOOTH | Don't care |

0 ~ 120 (sec) |

Setting of Dumping Time for Smoothing Filter |

||

| Z_SFT | File number between 0 and 999, WorkDirectory\SCAN\ Enter the data%03d_%03d.ini command (Front %03d : PORT number, Back %03d : Extra2 value) |

Don't care Two setting parameters are entered as FW, BW Zero Shift value(-9999.0 ~ 9999.0) |

Setting of Zero Shift |

||

| Z_CUT | Don't care Two setting parameters are entered as FW, BW Zero Shift value(-9999.0 ~ 9999.0) |

Setting of Zero Cut |

|||

| SPAN | Don't care Two setting parameters are entered as FW(0.000 ~ 9999.0), BW(0.000 ~ -9999.0) Zero Shift value |

Setting of Span Adjustment |

|||

| GAIN | Don't care Three setting parameters are entered as channel no.1 ~ no.4, U(Up Gain) or D(Down Gain), Gain value(0 ~ 204) |

Setting of Manual Gain |

|||

| RANGE | Don't care |

0 = FINISH, 1 = HI, 2 = LO |

Setting of Range Check |

||

| MULTI | 0 = FINISH, 1 = CH1, 2 = CH2, 3 = CH3, 4 = CH4 |

Setting of Measuring Path Fixing |

|||

| FUNC | 0 = FLOW, 1 = VELO |

Switching to Flow Meter or Velocity Meter |

|||

| UNIT | 0 = E-6, 1 = E-3, 2 = 1, 3 = E+3, 4 = E=6, 5 = E=6 |

Enter value between 0 and 13 (Unit by input value refers to <Table 2>) |

Selection of Flow Rate Unit |

||

| AOUT | 0 = CH1, 1 = CH2 |

-100.0 ~ 100.0 (%) |

Setting of A-OUT Check |

||

| STP | Don't care |

Don't care (Set without output value) |

Stopping Measurement |

In case of Measurement(RUN) status |

|

| RUN | Starting Measurement |

||||

| ISP | Stopping Integration |

In case of Measurement(RUN), COMMU/HOLD(STOP) status(always) |

|||

| IST | Starting Integration |

||||

| RGH | Changing Range to High |

In case of Measurement(RUN) INTEG. STOP status |

|||

| RGL | Changing Range to Low |

||||

| AGC | 0 = OFF, 1 = ON |

On/Off Selection of AGC |

In case of COMMU/HOLD(STOP) status |

||

| AGA | Enter 1 ~ 4 CH number |

Starting Automatic Gain Adjustment |

|||

| CQQ, CFI/CBI, CID, CCD, BASICDAT, CHECK , ERR | Don't care |

Memory start address to save read value |

Don't care |

Read command |

Refer to <Table 1> |

| <Table 4> Description for output type and output parameter which are used at UFL-20 Flow Meter Series communication driver | |||||

File Name |

WorkDirectory\SCAN\ data%03d_%03d.ini command input (Front %03d : PORT number, Back %03d : Extra2 value) |

Method |

Enter the number at single line which are classified by comma(,) |

Number/Character Input Method |

Enter the decimal number or character, etc at single line, properly |

| <Table 5> Setting parameters data input method which are used at UFL-20 Flow Meter Series communication driver | |

Setting Parameter |

Contents |

Range or Character |

First |

Type |

1:+:SNGL - One System, Unidirectional, Single range output, 1:+/-:SNGL - One System, Bi-directional, Single range output, 1:+:DBL - One System, Unidirectional, Double range output, 1:+/-:DBL - One System, Bi-directional, Double range output, 2:+/-:SNGL - Two System, Bi-directional, Single range output, 2:+:DBL - Two System, Unidirectional, Double range output, 2:+/-:DBL - Two System, Bi-directional, Double range output, SPECIAL - Special output. |

Second |

FW

|

0.00 ~ 99.00 |

Third |

FW

|

0.00 ~ 99.00 |

Fourth |

BW

|

0.00 ~ -99.00 |

Fifth |

BW

|

0.00 ~ -99.00 |

Sixth |

Setting Classfy |

F/B - Setting Classfy to FW/BW, H/L - Setting Classfy to HI/LO. |

Seventh |

Double Range Auto mode Setting |

ON - Automatic range, OFF - Manual range |

| <Table 6> Setting parameter input sequence and contents of FAOTYP and VAOTYP command which are used at UFL-20 Flow Meter Series communication driver | ||

Write example 1)

PORT : 0 STATION : 0 ADDRESS : 0000 EXTRA1 : STP EXTRA2 : 0

The setting parameter shown above is example of stopping(in case of Measurement mode) UFL-20 Flow Meter Series device connected with port no.0.

Write example 2)

PORT : 0 STATION : 0 ADDRESS : 0000 EXTRA1 : RUN EXTRA2 : 0

The setting parameter shown above is example of changing UFL-20 Flow Meter Series device connected with port no.0 as Measurement mode(in case of COMMU/HOLD).

Write example 3)

PORT : 0 STATION : 0 ADDRESS : 0000 EXTRA1 : FUNC EXTRA2 : 0

The setting parameter shown above is example of changing UFL-20 Flow Meter Series device connected with port no.0 as Velocity mode(in case of COMMU/HOLD).

Write example 4)

PORT : 0 STATION : 0 ADDRESS : 0000 EXTRA1 : UNIT EXTRA2 : 3

The setting parameter shown above is example of changing unit of UFL-20 Flow Meter Series device connected with port no.0 as M3/h and E+3(in case of COMMU/HOLD).

Write example 5)

PORT : 0 STATION : 0 ADDRESS : 0000 EXTRA1 : FAOTYP EXTRA2 : 2

The setting parameter shown above is example of setting(in case of COMMU/HOLD) Selection of Analog Output Type During Flow Meter value of UFL-20 Flow Meter Series device connected with port no.0. (But, seven data for setting factors has to be entered at 'WorkDirectory\SCAN\data000_002.ini' file)

Reference) Example for seven data of setting factors) 1:+:SNGL,50.0,0.0,0.0,0.0,F/B,OFF, (One System-Unidirectional-Single range output, FW High/Low Range 50.0, 0.0, BW High/Low Range ¡¦,)

Connection of RS-232C communication cable of UFL-20 Flow Meter Series device and basic power are as follows.

Communication cable connection

Connect RS-232C communication cable to RS232C terminal(refer to <Figure 4>) of UFL-20 Flow Meter Series device.

<Figure 4> is appearance of UFL-20 Flow Meter Series device.

|

| <Figure 4> Appearance of UFL-20 Flow Meter Series device |

Basic power connection

Connect basic power of 220V AC, etc to L , N terminal of UFL-20 Flow Meter Series device such as <Figure 4>.

1. Power switch ON

2. Press MENU Key

3. ¡°5693¡±+ ENT (Confirm whether show S1 at upper of DISPLAY window)

4. MENU no. 1 INPUT + ENT

5. MENU no. 1 MEAS.DATA + ENT

6. Press number ¡°0¡±, just once

7. MENU no.7 OTHER DATA + ENT

8. ¡°1126¡± + ENT

9. MENU no.3 OPTION + ENT

10. MENU no.2 RS232C + ENT

11. OFF -> ON (Press direction KEY ¡è) + ENT

12. Press EXIT Key (Go to default screen)

13. Press MENU Key

14. MENU no.1 INPUT + ENT

15. MENU no.3 RS232C + ENT

16. MENU no.1 BAUD RATE + ENT

17. Designate communication speed(9600) by using direction Key ¡è, ¡é + ENT

18. MENU no.2 REMOTE HI/LO + ENT

19. Select MENU no.2 RS232C + ENT

20. Press EXIT Key (Go to default screen)