Koyama Torquewish Controller is the driver to communicate with Electric screw-driver of Koyama Co., Ltd. in Japan.

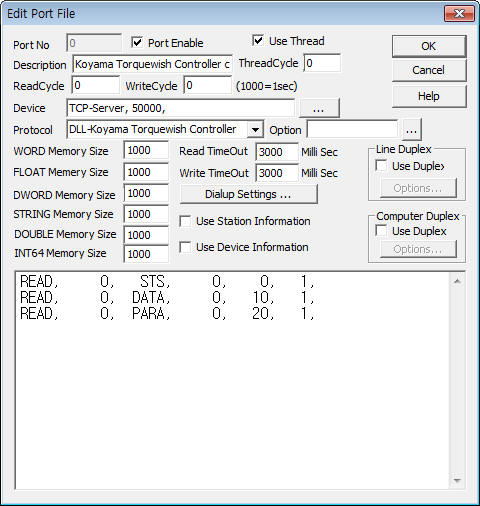

<Figure 1> is read setting example of Koyama Torquewish Controller communication driver.

|

| <Figure 1> Read setting example of Koyama Torquewish Controller communication driver |

Device part of <Figure 1> input device type( TCP Server ), service port( 50000 ) respectively, accordint to the setting of controller.

Server for Koyama Torquewish controller have to use 'no. 254' last IP address. ( example : 192.168.1.254 )

Also, Koyama Torquewish controller driver supports 1:1 connection. ( TCP-Server )

Read schedule of Koyama Torquewish Controller communication driver

Read schedule setting parameters are as follows:

1) station – don't care.( fixed to 0)

2) read command – Command : STS, PARA, DATA ( refer to <Table 1> ).

3) read start address – don't care.

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read size – fixed to 1.

Read schedule example)

READ, 0, STS, 0, 0, 1,

READ, 0, DATA, 0, 10, 1,

READ, 0, PARA, 0, 20, 1,

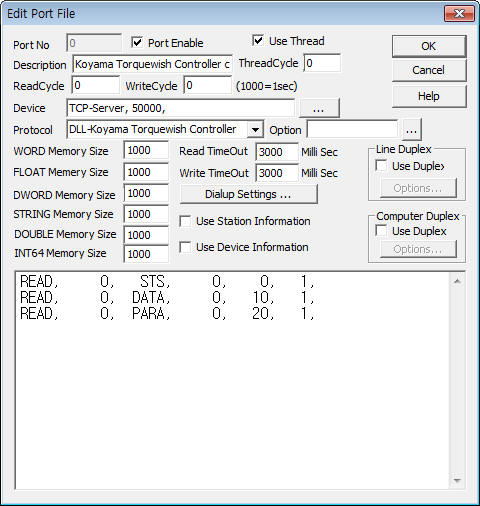

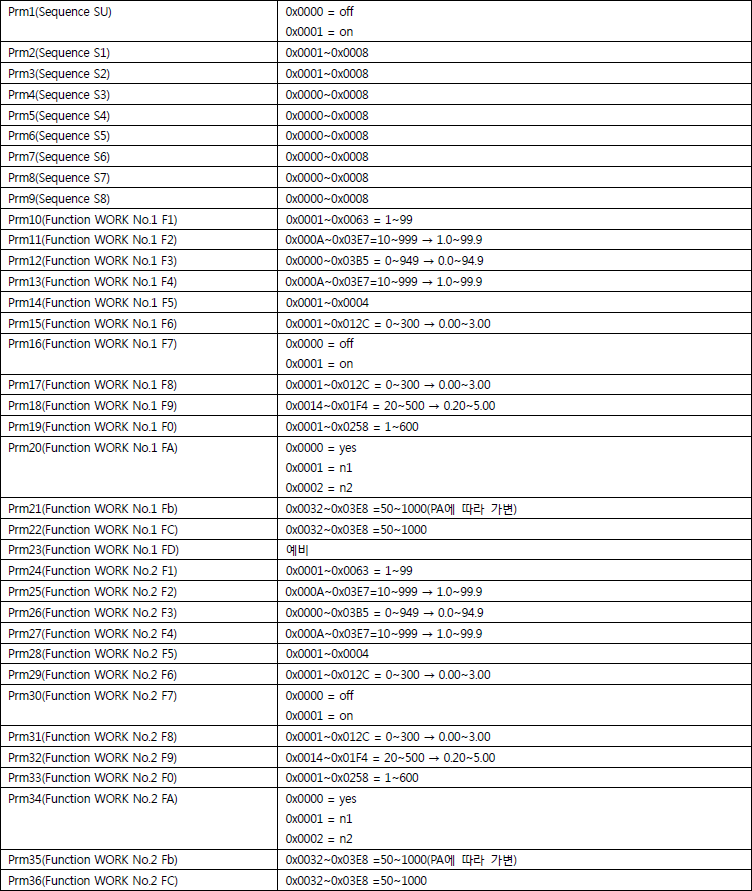

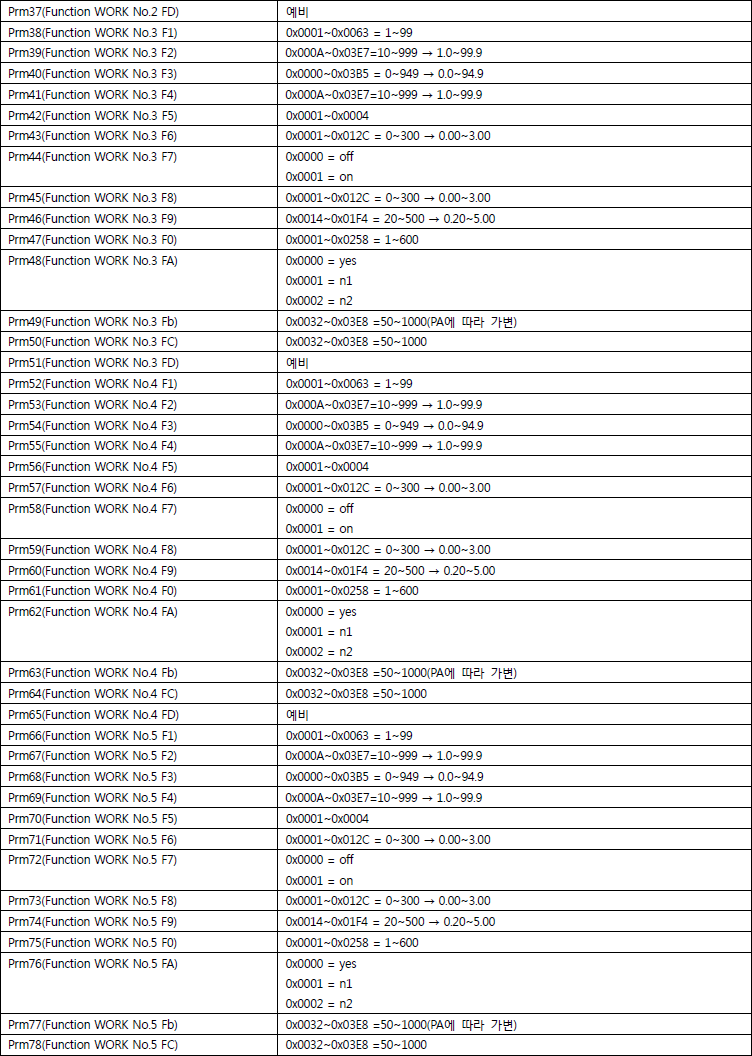

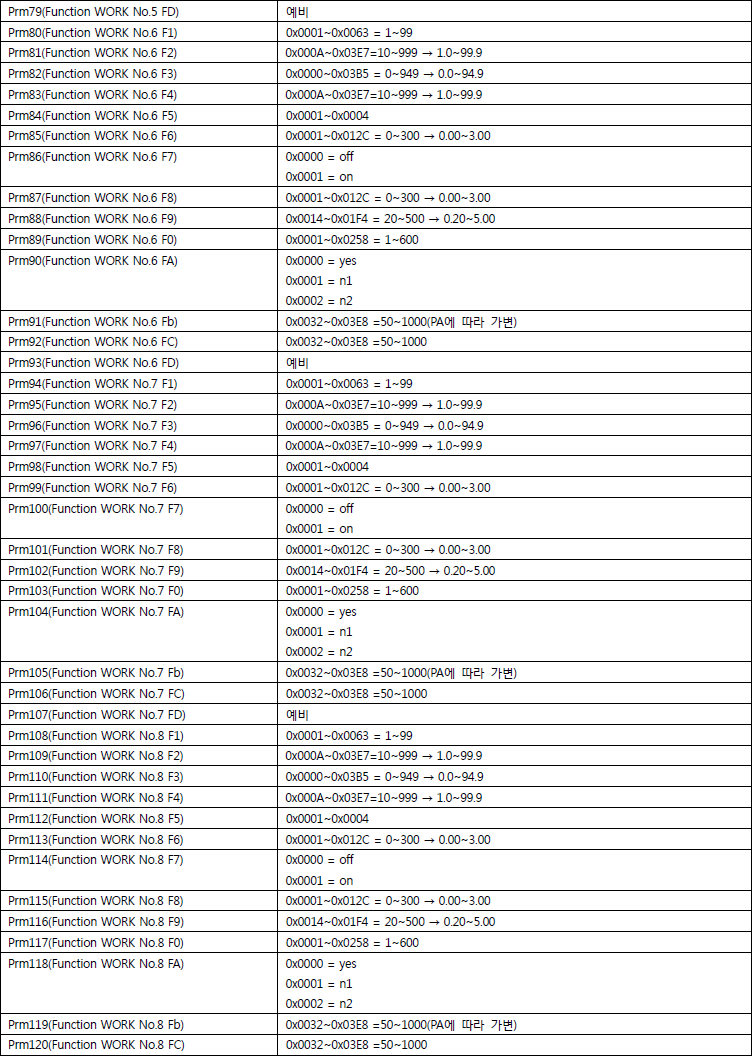

<Table 1> is read command and readed data saving value of Koyama Torquewish Controller communication driver.

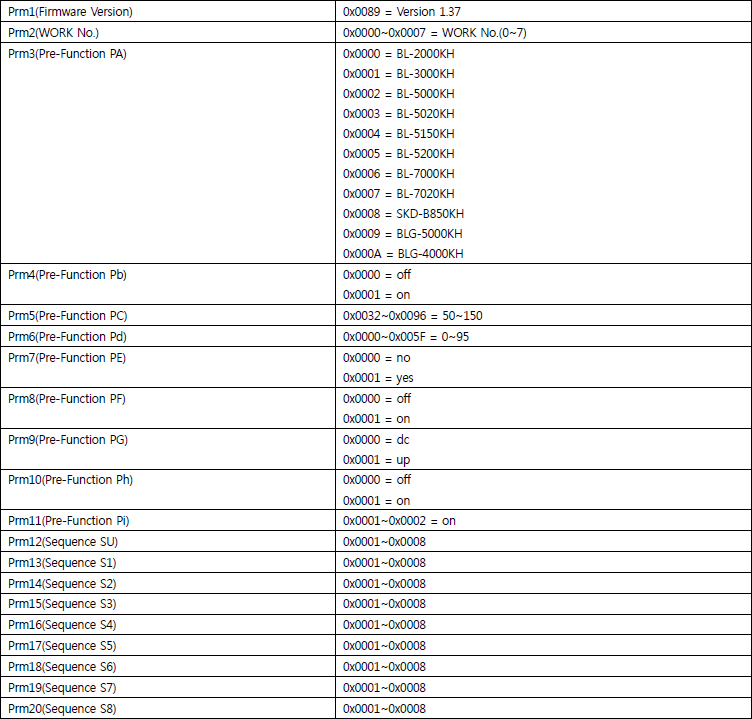

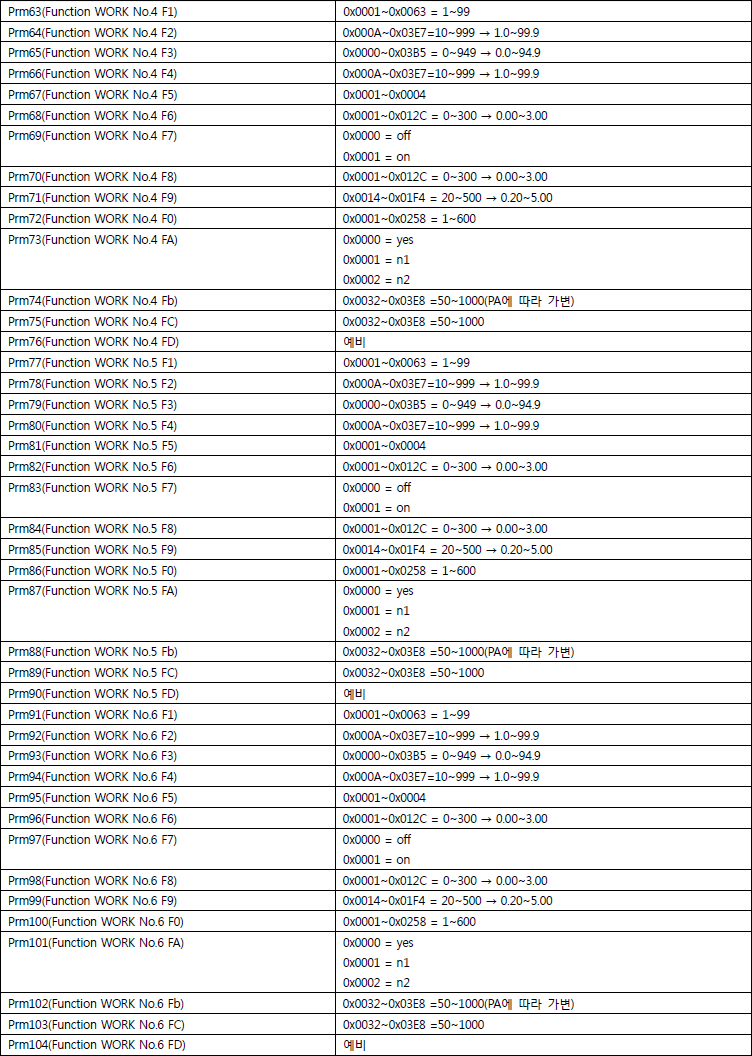

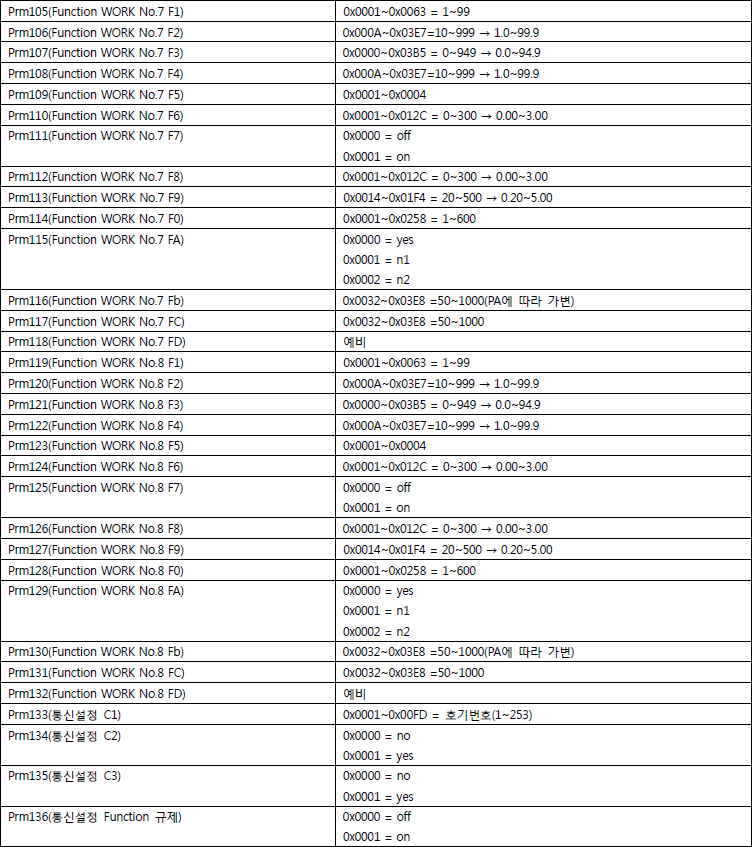

<Table 2> is contents and setting value for Parameter 1 ~ 136.

Read Command |

Contents |

Data saving value of Communication Server |

Remarks |

STS |

Read of current status |

Saving Start Address + 0 : WORK no. (0 ~ 7) Saving Start Address + 1 : operation mode (0 = normal, 1 = Pre-Function, 2 = Function setting, 3 = sequence setting, 4 = communication setting, 5 = All Clear, 6 = Version display, 7 = Parameter initialize) Saving Start Address + 2 : screw joint status (0 = count end of screw joint, 1 = count end of screw joint) Saving Start Address + 3 : screw joint count (0 ~ 99) Saving Start Address + 4 : Data changing flag (0 = Data not changed, 1 = Data changed) |

|

PARA |

Read of setting value |

Saving Start Address + 0 ~ 135 : parameter 1 ~ 136 |

refer to <Table 2> |

DATA |

Read of data value |

Saving Start Address + 0 : screw joint mode (0 = don't use Torque Up sensor, 1 = use Torque Up sensor, 2 = pre-joint) Saving Start Address + 1 : Torque output level (0 ~ 1000) Saving Start Address + 2 : result of screw joint (0 = none, 1 = OK, 2 = END, 3 = REVERSE, 4 = RESET, 5 = NG(SHORT), 6 = NG(LONG), 7 = NG(TURNOVER), 8 = NG(TORQUEUP), 9 = ALL RESET) Saving Start Address + 3 : WORK no. (0 ~ 7) Saving Start Address + 4 : F1 (1 ~ 99) Saving Start Address + 5 : FA (0 = yes, 1 = n1, 2 = n2) Saving Start Address + 6 : F4 or Fb (F4 : 10~999 ¡æ 1.0~99.9, Fb : 50~1000) Saving Start Address + 7 : FC (50~1000) Saving Start Address + 8 : number of TURN (10~999 ¡æ 0.0~99.9) Saving Start Address + 9 : status of screw joint (0 = count end of screw joint, 1 = count start of screw joint) |

|

| <Table 1> Read command and readed data saving value of Koyama Torquewish Controller communication driver | |||

|

| <Table 2> Contents and setting value for Parameter 1 ~ 136 |

Koyama Torquewish Controller communication driver store the same data in WORD, DWORD, FLOAT, DOUBLE memory, but the data format are different.

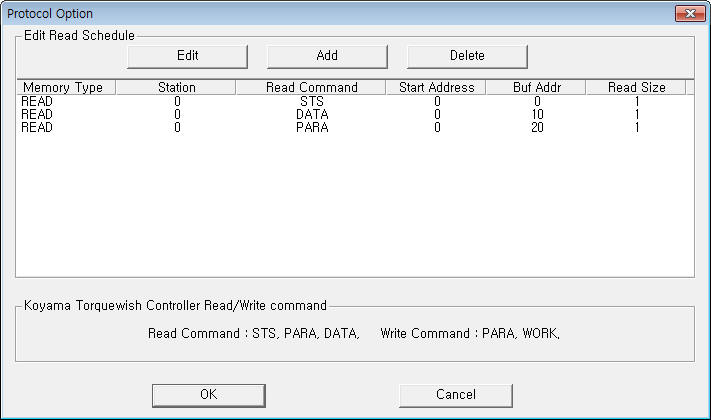

If you click the icon ![]() in protocol option part at

<Figure 1>, you

can see the dialog box such as <Figure 2>. you can also set read schedule by

using this part.

in protocol option part at

<Figure 1>, you

can see the dialog box such as <Figure 2>. you can also set read schedule by

using this part.

|

| <Figure 2> Example of Koyama Torquewish Controller communication driver¡¯s Option dialog box |

You can set read schedule by using

![]() ,

,

![]() ,

,

![]() button and listbox of <Figure

2>.

button and listbox of <Figure

2>.

|

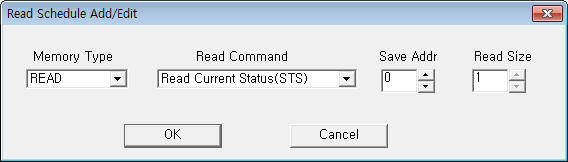

| <Figure 3> Example of Koyama Torquewish Controller communication driver¡¯s read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialogue box of <Figure 2>, dialogue box of <Figure 3> is shown.

You can control by using 'write settings'.

Digital Write

Digital write and analog write have the same setting parameters except output value.

Analog Write

Analog write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION don't care.

3) ADDRESS 0 ~ 125 parameter number when PARA write command.

4) Extra1 write command : PARA, WORK

PARA : parameter setting command,

WORK : work number setting command. ( output value = 0 ~ 7)

5) Extra2 use of size fiend data.

0 : use,

1 : don't use.

<Table 3> is address and contents for parameter setting command.

|

| <Table 3> Address and contents for parameter setting command |

Write example 1)

PORT : 0 STATION : 0 ADDRESS : 1 EXTRA1 : PARA EXTRA2 : 0

The setting parameter shown above is 'sequence S1' setting example.

Write example 2)

PORT : 0 STATION : 0 ADDRESS : 1 EXTRA1 : PARA EXTRA2 : 0

The setting parameter shown above is 'Function WORK No. 8 FC' setting example.

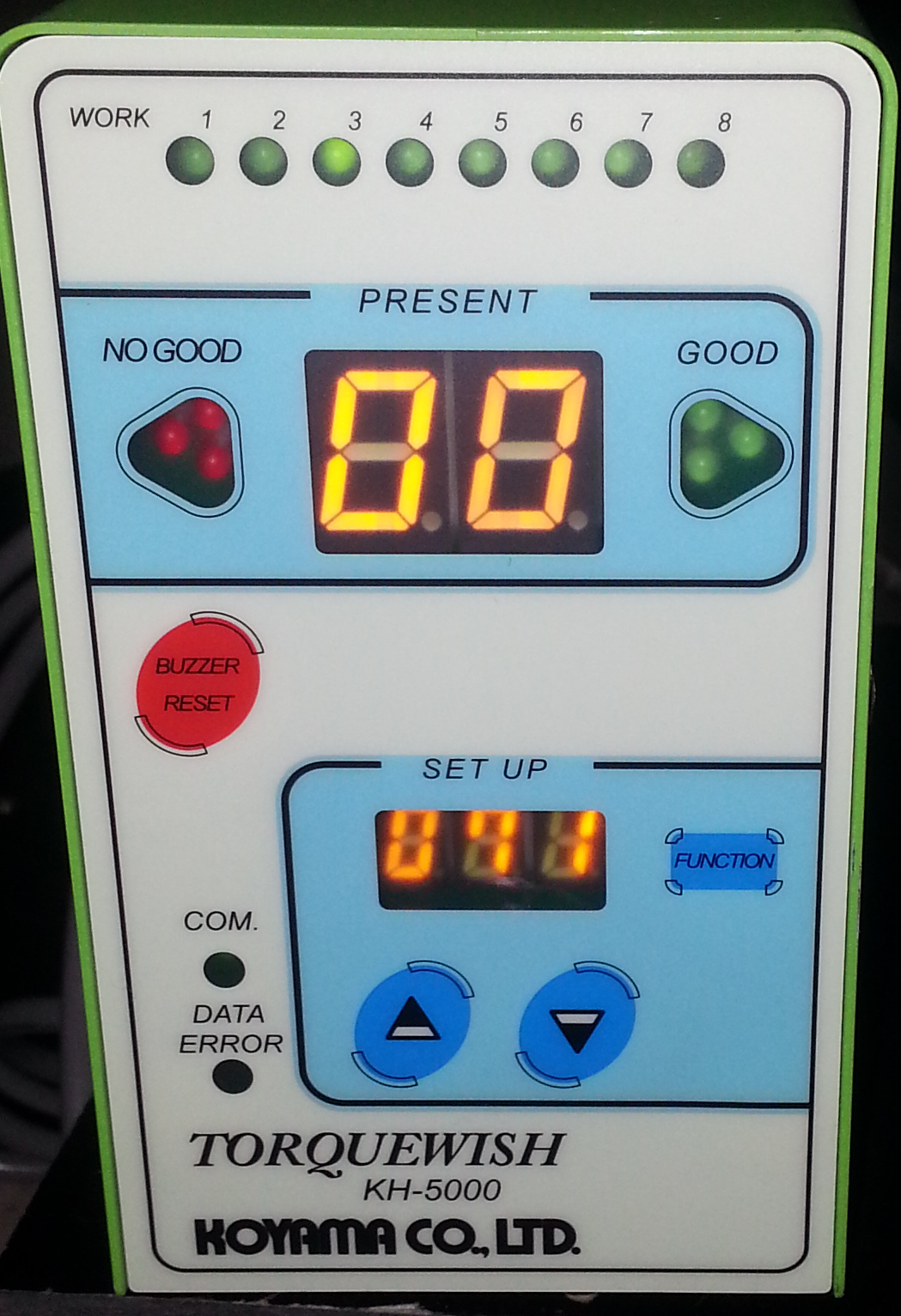

<Figure 4> shows the appearance of Koyama Torquewish Controller.

|

| <Figure 4> Appearance of Koyama Torquewish Controller |