TGE OMiD Controller Communication Driver is the driver to communicate with OMiD controller of TaeGwang E&C in Korea.

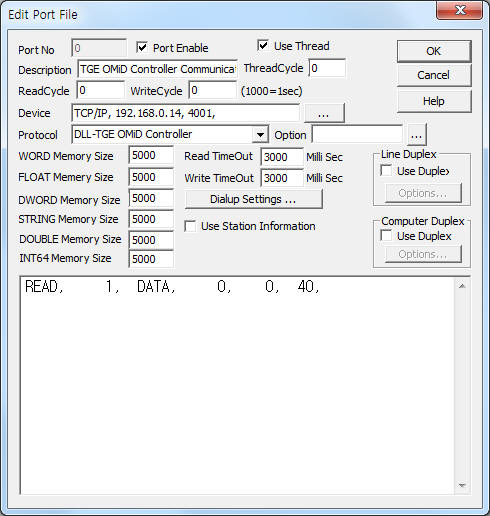

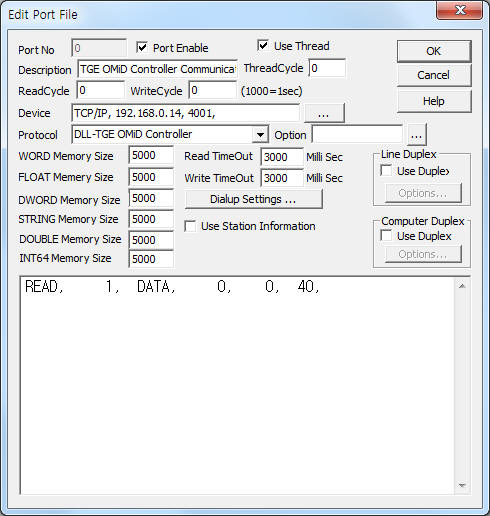

<Figure 1> is read setting example of TGE OMiD Controller communication driver.

|

| <Figure 1> Read setting example of TGE OMiD Controller communication driver |

Device part of <Figure 1> input Device type(TCP/IP, IP address of equipment(192.168.0.14), Service port(4001) respectively.

TGE OMiD Controller communication driver¡¯s read schedule

Read schedule setting parameters are as follows:

1) STATION – Don't care.

2) Read command – Read Command = DATA.

3) Read Start Address – Read start address. ( Refer to <Table 1> )

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read Size – Read word size = 1 ~ 126.

Read schedule example)

READ, 1, DATA, 0, 0, 20,

<Table 1> is contents for each general reference register address of TGE OMiD Controller communication driver.

<Table 2> is a description of controller status for each Byte unit.

| Address | Contents | Read/Write | Remarks |

| 0 | Count of OMiD | Read/Write | High Byte : Equipment number, Low Byte : Total count |

| 1 | Current time of controller - Year | ||

| 2 | Current time of controller - Month | 1 ~ 12 | |

| 3 | Current time of controller - Day | 1 ~ 31 | |

| 4 | Current time of controller - Hour | 0 ~ 23 | |

| 5 | Current time of controller - Minute | 0 ~ 45 | |

| 6 | Current time of controller - Milli second | 0 ~ 60000 mSec | |

| 7 | Operation step | Read only | 0 : Waiting, 1 : Step Seq1 2 : Step Seq2 3 : Step Seq3 (Oil Pumping) 4 : Step Seq3 (Moisture) 5 : Step Seq3 (Hitting) 6 : Step Seq4 (Measuring) 7 : Waiting for restart |

| 8 | Control status | Read/Write | Bit 0 : Sol Valve 1 On/Off Bit 1 : Sol Valve 2 On/Off Bit 2 : Sol Valve 3 On/Off Bit 3 : Fan On/Off Bit 4 : Gas Heat On/Off Bit 5 : Shell Heat On/Off Bit 6 : Oin Pump On/Off Bit 7 : Air Pump On/Off Bit 8 ~ 15 : Reserved |

| 9 | Hydrogen (ppm) High Word | Read only | scale = 1/100 |

| 10 | Hydrogen (ppm) low Word | ||

| 11 | Moisture (ppm) High Word | ||

| 12 | Moisture(ppm) Low Word | ||

| 13 ~ 14 | Reserved | ||

| 15 | Realtime Hydrogen value( V ) | scale = 1/1000 | |

| 16 | Realtime Moisturevalue( % ) | scale = 1/100 | |

| 17 | Controller status | Byte Unit value, Refer to <Table 2> | |

| 18 | Operation setting | Read/Write | 0 : Manual, 1 : Auto, 2 : Stop |

| 19 | Hydrogen Over value High Word | ||

| 20 | Hydrogen Over value Low Word | ||

| 21 | Hydrogen Danger value High Word | ||

| 22 | Hydrogen Danger value Low Word | ||

| 23 | Moisture Over value High Word | ||

| 24 | Moisture Over value Low Word | ||

| 25 | Moisture Danger value High Word | ||

| 26 | Moisture Danger value Low Word | ||

| 27 ~ 37 | Reserved | ||

| 38 | Front Index of Record | 0 ~ 79 (number of 80 ) | |

| 39 | Rear Index of Record | ||

| 40 ~ 45 | Year, Month, Day, Hour, Minute, Milli second of Record 0 | Read only | |

| 46 | Contents of Record 0 | ||

| 47 | Variables of Record 0 | ||

| 48 ~ 55 | Time(Year, ...), Contents, Variables of Record 1 | ||

| 56 ~63 | Time(Year, ...), Contents, Variables of Record 2 | ||

| ... | ... | ||

| 672 ~ 679 | Time(Year, ...), Contents, Variables of Record 79 | ||

| <Table 1> Contents for each general reference register address of TGE OMiD Controller communication driver | |||

| High Byte | Low Byte | Meaning |

| 0 | x | Hydrogen Normal |

| 1 | x | Hydrogen Over |

| 2 | x | Hydrogen Danger |

| x | 0 | Moisture Normal |

| x | 1 | Moisture Over |

| x | 2 | Moisture Danger |

| <Table 2> Description of controller status for each Byte unit | ||

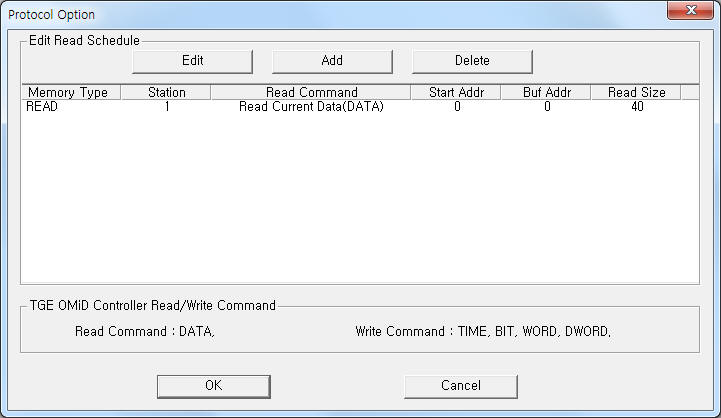

If you click the icon ![]() in protocol option part, you

can see the dialog box such as <Figure 2>. you can also set read schedule by

using this part.

in protocol option part, you

can see the dialog box such as <Figure 2>. you can also set read schedule by

using this part.

|

| <Figure 2> Example of TGE OMiD Controller communication driver¡¯s Option dialog box |

You can set read schedule by using ![]() ,

, ![]() ,

, ![]() button and listbox

of <Figure 2>.

button and listbox

of <Figure 2>.

|

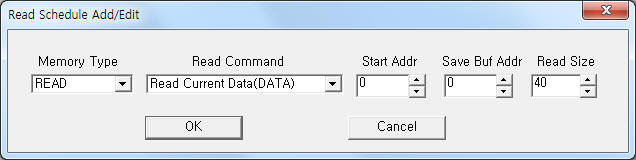

| <Figure 3> Example of TGE OMiD Controller communication driver¡¯s read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialog box of <Figure 2>, dialog box of <Figure 3> is shown.

You can write TGE OMiD Controller by using write settings.

Bit Write

Bit write and word write have the same setting parameters except output value.

Word Write

Word write setting parameters are as follows:

2) STATION Don't care.

3) ADDRESS Write start address. ( Refer to <Table 1> ).

4) Extra1 Write command = BIT, WORD, DWORD, TIME.

BIT : bit unit write( bit operation after 1 WORD data read),

WORD : output of Word unit value(0 ~ 65535),

DWORD : output of Double Word value,

TIME : send current date/time to controller(time syncronization).

5) Extra2 Write command : BIT - setting of 0 ~ 15 bit position,

other write command : don't care.

Write example 1)

PORT:0, station:1, ADDRESS:0008, Extra1:BIT, Extra2 : 3

The setting parameter shown above is an example of write for Fan On/Off control. (Bit position = 3 )

Write example 2)

PORT:0, station:1, ADDRESS:0018, Extra1:WORD, Extra2 : 0

The setting parameter shown above is an example of write for Operation setting. ( 0 : Manual, 1 : Auto, 2 : Stop )

Write example 3)

PORT:0, station:1, ADDRESS:0019, Extra1:DWORD, Extra2 : 0

The setting parameter shown above is an example of write for Hydrogen over value high 2 word setting.

Block write

TGE OMiD Controller communication driver don¡¯t support ¡®Block write¡¯.

Please connect UTP(direct) Ethernet communication cable to TGE OMid equipment such as <Figure 4>.

<Figure 4> is connection example of UTP Ethernet communication cable to TGE OMiD equipment.

<Figure 5> is appearance of TGE OMiD equipment.

|

| <Figure 4> Connection example of UTP Ethernet communication cable to TGE OMiD equipment |

|

| <Figure 5> Appearance of TGE OMiD equipment |