S-TURBO Compressor communication driver is the driver to communicate with TURBO Compressor device developed in Korea.

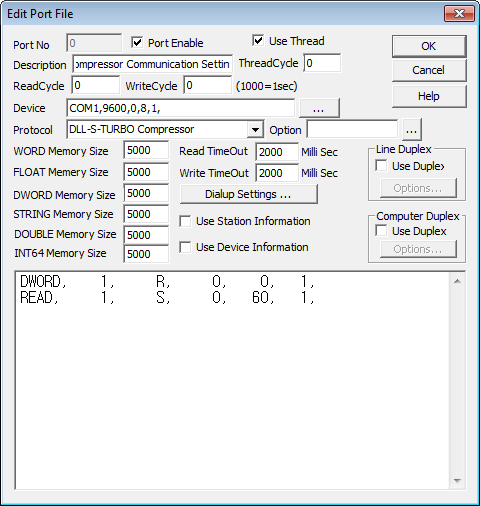

<Figure 1> is read setting example of S-TURBO Compressor.

|

| <Figure 1> Read setting example of S-TURBO Compressor |

Device part of <Figure 1> input Device type(COM1), Com Baud(9600), Parity Bit(0), Data Bit(8), Stop Bit(1).

Read schedule example)

| READ | STATION | Read Command | Read Start Address | Memory Save Address | Read Size |

| DWORD, | 1, | R, | 0, | 0, | 1, |

| READ, | 1, | S, | 0, | 60, | 1, |

1) STATION : Device STATION number between 0 and 15.

2) Read Command : Command to read. Refer to <Table 1> and <Table 5>.

R = Run Data, S = Set Data

3) Read Start Address : Don't care.

4) Save Start Address for Communication Server : Buf position to save the read status value.

5) Read Size : Size to read. (Fixed according to type to read, Always fixed as 1)

R, S = 58

Notice) S-TURBO Compressor communication driver's read data is saved at same address of WORD/FLOAT/DWORD memory as same value.

Save Address |

Save Contents |

Range |

Memory Save Addr + 0 ~ 4 |

Sensor, Status value of Sensor 1 ~ 4 |

00 ~ FF (Status value by bit) Refer to <Table 2> and <Table 3> |

Memory Save Addr + 5 ~ 9 |

Alarm1, Alarm11 ~ 14 (Light trouble) |

|

Memory Save Addr + 10 ~ 14 |

Alarm2, Alarm21 ~ 24 (Heavy trouble) |

|

Memory Save Addr + 15 |

Discharge Air Pressure |

0 ~ 9999 |

Memory Save Addr + 16 |

2 Stage Intake Temp |

|

Memory Save Addr + 17 |

3 Stage Intake Temp |

|

Memory Save Addr + 18 |

Motor Current |

|

Memory Save Addr + 19 |

Air Filter Differential Pressure |

|

Memory Save Addr + 20 |

Oil Pressure |

|

Memory Save Addr + 21 |

Oil Temp |

|

Memory Save Addr + 22 |

Oil Filter Differential Pressure |

|

Memory Save Addr + 23 |

1 Stage Vibration |

|

Memory Save Addr + 24 |

2 Stage Vibration |

|

Memory Save Addr + 25 |

3 Stage Vibration |

|

Memory Save Addr + 26 |

1 Stage Gap Voltage |

|

Memory Save Addr + 27 |

2 Stage Gap Voltage |

|

Memory Save Addr + 28 |

3 Stage Gap Voltage |

|

Memory Save Addr + 29 |

Coolant Supply Temp |

|

Memory Save Addr + 30 |

1 Stage Intercooler Temp |

|

Memory Save Addr + 31 |

2 Stage Intercooler Temp |

|

Memory Save Addr + 32 |

Oil Cooler Temp |

|

Memory Save Addr + 33 |

4 Stage Vibration |

|

Memory Save Addr + 34 |

5 Stage Vibration |

|

Memory Save Addr + 35 |

Total Operation Time |

0 ~ 99999 |

Memory Save Addr + 36 |

Load Operation Time |

|

Memory Save Addr + 37 |

Load Count |

|

Memory Save Addr + 38 |

Maneuver Count |

|

Memory Save Addr + 39 |

Lubricant Life |

|

Memory Save Addr + 40 |

Motor BRG Temp Before |

0 ~ 9999 |

Memory Save Addr + 41 |

Motor BRG Temp After |

|

Memory Save Addr + 42 |

Motor Winding Temp( R ) |

|

Memory Save Addr + 43 |

Motor Winding Temp( S ) |

|

Memory Save Addr + 44 |

Motor Winding Temp( T ) |

|

Memory Save Addr + 45 |

2 Stage Intake Pressure |

|

Memory Save Addr + 46 |

3 Stage Intake Pressure |

|

Memory Save Addr + 47 |

3 Stage Discharge Temp |

|

Memory Save Addr + 48 |

A/C Discharge Temp |

|

Memory Save Addr + 49 |

Oil Tank Temp |

|

Memory Save Addr + 50 |

Coolant Flow |

|

Memory Save Addr + 51 |

Discharge Air Flow |

|

Memory Save Addr + 52 |

IGV Opening |

|

Memory Save Addr + 53 |

BOV Opening |

|

Memory Save Addr + 54 ~ 57 |

COMP, OUTA, OUTB and INPUT bit value |

00 ~ FF (Status value by bit) Refer to <Table 4> |

| <Table 1> Save address and save contents of read value for R (Run Data) read command | ||

| Contents | No.7 bit | No.6 bit | No.5 bit | No.4 bit | No.3 bit | No.2 bit | No.1 bit | No.0 bit |

| Sensor | Oil Filter Differential Pressure | Oil Temp | Oil Pressure Upper Limit | Air Filter Differential Pressure | Motor Current | 3 Stage Intake Temp | 2 Stage Intake Temp | Discharge Air Pressure |

| Sensor1 | 1 Stage Intercooler Temp |

Coolant Supply Temp | 3 Stage Gap Voltage | 2 Stage Gap Voltage | 1 Stage Gap Voltage | 3 Stage Vibration | 2 Stage Vibration | 1 Stage Vibration |

| Sensor2 | Oil Cooler Temp | 2 Stage Intercooler Temp | ||||||

| Sensor3 | 3 Stage Discharge Temp | 3 Stage Intake Pressure | 2 Stage Intake Pressure Upper Limit | Motor Winding Temp ( T ) |

Motor Winding Temp ( S ) |

Motor Winding Temp ( R ) |

Motor BRG Temp After | Motor BRG Temp Before |

| Sensor4 | IGV Opening | Discharge Air Flow | Coolant Flow | Oil Tank Temp | A/C Discharge Temp | |||

| <Table 2> Status value by bit of Sensor and Sensor no.1 ~ no.4 | ||||||||

| Contents | No.7 bit | No.6 bit | No.5 bit | No.4 bit | No.3 bit | No.2 bit | No.1 bit | No.0 bit |

| Alarm1, Alarm2 | Oil Filter Differential Pressure | Oil Temp | Oil Pressure Upper Limit | Air Filter Differential Pressure | Motor Current | 3 Stage Intake Temp | 2 Stage Intake Temp | Auxiliary Equipment Error |

| Alarm11, Alarm21 | Coolant Supply Temp | 3 Stage Gap Voltage | 2 Stage Gap Voltage | 1 Stage Gap Voltage | 3 Stage Vibration | 2 Stage Vibration | 1 Stage Vibration | |

| Alarm12, Alarm22 | Oil Temp Lower Limit | Oil Temp Upper Limit | ||||||

| Alarm13, Alarm23 | 3 Stage Discharge Temp | Motor Winding Temp ( T ) |

Motor Winding Temp ( S ) |

Motor Winding Temp ( R ) |

Motor BRG Temp After | Motor BRG Temp Before | ||

| Alarm14, Alarm24 | Oil Level | Surge | Discharge Air Flow | Coolant Flow | Oil Tank Temp | A/C Discharge Temp | ||

| <Table 3> Status value by bit of light trouble( Alarm1, Alamr11 ~ 14 ) and heavy trouble( Alarm2, Alamr21 ~ 24 ) | ||||||||

| Contents | No.7 bit | No.6 bit | No.5 bit | No.4 bit | No.3 bit | No.2 bit | No.1 bit | No.0 bit |

| OUTA | IGV OPEN | IGV CLOSE | MOTOR LED | OIL LED | HIGH ALARM | LOW ALARM | START LED | REMOTE LED |

| OUTB | MOTOR | FAN | OIL PUMP | DIS VALVE | WATER VALVE | HEATER | B.O.V | OIL LED |

| INPUT | EMG SW | SPAR BIT | REMOTE IN | NO LOAD | SERGE | OIL LEVEL | X | X |

| <Table 4> Status value by bit of OUTA, OUTB and INPUT | ||||||||

Save Address |

Save Contents |

Memory Save Addr + 0 |

Oil Pressure Lower Limit (Heavy trouble) |

Memory Save Addr + 1 |

Oil Pressure Upper Limit (Heavy trouble) |

Memory Save Addr + 2 |

Oil Filter Differential Pressure (Heavy trouble) |

Memory Save Addr + 3 |

1, 2, 3 Stage Vibration (Heavy trouble) |

Memory Save Addr + 4 |

Intake Air Temp (Heavy trouble) |

Memory Save Addr + 5 |

Main Oil Pump Pressure (Heavy trouble) |

Memory Save Addr + 6 |

Motor Bearing Temp (Heavy trouble) |

Memory Save Addr + 7 |

Winding RST High Temp (Heavy trouble) |

Memory Save Addr + 8 |

Coolant Flow (Heavy trouble) |

Memory Save Addr + 9 |

Discharge Pressure (Heavy trouble) |

Memory Save Addr + 10 |

Reload Pressure |

Memory Save Addr + 11 |

Current Value Upper Limit |

Memory Save Addr + 12 |

Current Value Lower Limit |

Memory Save Addr + 13 |

Oil Pressure Upper Limit (Light trouble) |

Memory Save Addr + 14 |

Oil Pressure Lower Limit (Light trouble) |

Memory Save Addr + 15 |

Oil Temp Upper Limit (Light trouble) |

Memory Save Addr + 16 |

Oil Temp Lower Limit (Light trouble) |

Memory Save Addr + 17 |

Oil Filter Differential Pressure (Light trouble) |

Memory Save Addr + 18 |

1, 2, 3 Stage Vibration (Light trouble) |

Memory Save Addr + 19 |

Intake Air Temp (Light trouble) |

Memory Save Addr + 20 |

Air Filter Differential Pressure (Light trouble) |

Memory Save Addr + 21 |

Gap Voltage Upper Limit (Light trouble) |

Memory Save Addr + 22 |

Gap Voltage Lower Limit (Light trouble) |

Memory Save Addr + 23 |

Heavy Trouble Vibration |

Memory Save Addr + 24 |

Light Trouble Vibration |

Memory Save Addr + 25 |

Heater ON Temp |

Memory Save Addr + 26 |

Heater OFF Temp |

Memory Save Addr + 27 |

Motor Heavy Trouble Current |

Memory Save Addr + 28 |

Vibration Delay Time |

Memory Save Addr + 29 |

C/T Magnification |

Memory Save Addr + 30 |

1, 2, 3 Stage Vibration Filter |

Memory Save Addr + 31 |

Control Constant |

Memory Save Addr + 32 |

BOV Modulation |

Memory Save Addr + 33 |

No-Load Pressure |

Memory Save Addr + 34 |

No-Load Control Value |

Memory Save Addr + 35 |

Current Dead Zone |

Memory Save Addr + 36 |

Static Pressure Control Value |

Memory Save Addr + 37 |

Pressure Dead Zone |

Memory Save Addr + 38 |

Pressure PWM Time |

Memory Save Addr + 39 |

PWM Pressure Current Interval |

Memory Save Addr + 40 |

Current PWM Interval |

Memory Save Addr + 41 |

BOV Output Control |

Memory Save Addr + 42 |

Load Delay Time |

Memory Save Addr + 43 |

Main Oil Pump Pressure Low (Light trouble) |

Memory Save Addr + 44 |

Main Oil Pump Pressure High (Light trouble) |

Memory Save Addr + 45 |

Motor Bearing Temp High (Light trouble) |

Memory Save Addr + 46 |

Winding RST High Temp (Light trouble) |

Memory Save Addr + 47 |

Coolant Flow Low (Light trouble) |

Memory Save Addr + 48 |

Operation 7 Side 1 ~ 4 Clause Control |

Memory Save Addr + 49 |

Operation 7 Side 5, 8 Side 1 ~ 3 D |

Memory Save Addr + 50 |

Operation 8 Side 4 ~ 5, 9 Side 1 ~ 2 |

Memory Save Addr + 51 |

Operation 9 Side 3 ~ 4, 10 Side 1 ~ 2 |

Memory Save Addr + 52 |

BOV Proportion Value |

Memory Save Addr + 53 |

BOV Integral Value |

Memory Save Addr + 54 |

BOV Integral Value |

Memory Save Addr + 55 |

BOV OFF Deviation |

Memory Save Addr + 56 |

BOV No-Load % |

Memory Save Addr + 57 |

Discharge Air Flowmeter |

| <Table 5> Save address and save contents of read value for S ( Set Data ) read command | |

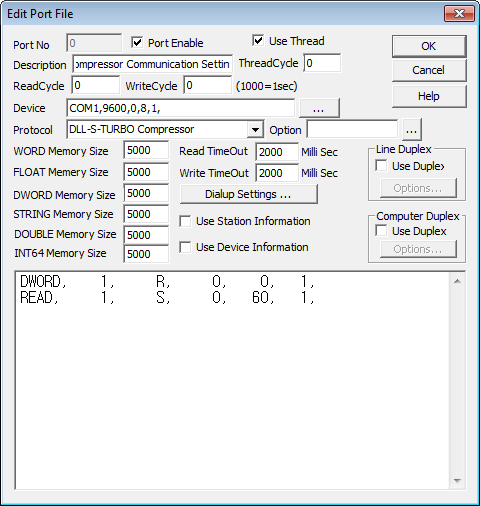

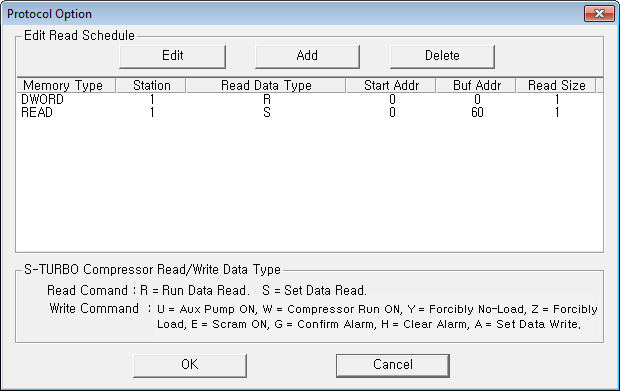

If you click the icon ![]() in protocol

option part, you can see the dialog box such as <Figure 2>. You can also set

read schedule by using this part.

in protocol

option part, you can see the dialog box such as <Figure 2>. You can also set

read schedule by using this part.

|

| <Figure 2> Example of S-TURBO Compressor driver's Option dialog box |

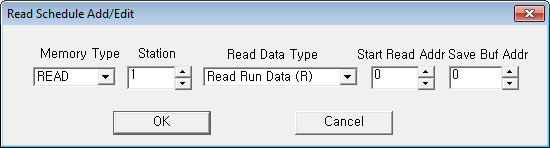

You can set read schedule by using ![]() ,

, ![]() ,

, ![]() button and

listbox of <Figure 3>.

button and

listbox of <Figure 3>.

|

| <Figure 3> Example of S-TURBO Compressor driver's read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialog box of <Figure 2>, dialog box of <Figure 3> is shown.

You can read/write the data by using digital/analog output command.

Digital Write

You can read the data or control as bit unit by using digital write.

Digital write setting parameters are as follows:

1) PORT Connected Port number. ( 0 ~ 255 )

2) STATION Device's STATION number( 0 ~ 15 ).

3) Address Address to set. (Use, in case of A output command)

4) Extra1 Output command.

A : Send setting value, ( Use analog output, Digital output writes 0 or 1 value)

U : Auxiliary PUMP ON,

W : Compressor Operation ON,

Y : Forcing No-Load,

Z : Forcing Load,

E : Emergency Shutdown ON,

G : Alarm Check,

H : Alarm Clear,

R, S : Run/Set Data read command

5) Extra2 R, S Output Command : Memory start address to save read value, Etc Output Command : Don't care

Write example 1)

Station : 1 Address : 0000 Extra1 : U, EXTRA2 : Blank

If you set as above and write digital value, you can ON aux PUMP of no.1 S-TURBO Compressor device. (Both ON/OFF commands do motion of aux PUMP ON)

Write example 2)

Station : 1 Address : 0000 Extra1 : E, EXTRA2 : Blank

If you set as above and write digital value, you can ON scram of no.1 S-TURBO Compressor device. (Both ON/OFF commands do motion of scram ON)

Write example 3)

Station : 1 Address : 0000 Extra1 : H, EXTRA2 : Blank

If you set as above and write digital value, you can clear alarm of no.1 S-TURBO Compressor device. (Both ON/OFF clear alarm)

Write example 4)

Station : 1 Address : 0000 Extra1 : R, EXTRA2 : 200

If you set as above and write digital value, you can read Run Data of no.1 S-TURBO Compressor device and save from no.200 address of WORD/FLOAT/DWORD memory. (Save at memory no.200 to no.257 address)

Analog Write

You can set operation command, BOV operating pressure and etc, by using analog write.

Analog write setting parameters are as follows :

1) PORT Connected Port number. ( 0 ~ 255 )

2) STATION Device's STATION number ( 0 ~ 15 ).

3) Address Address to set. (Use, in case of A output command)

4) Extra1 Output command.

A : Send setting value,

U : Auxiliary PUMP ON,

W : Compressor Operation ON,

Y : Forcing No-Load,

Z : Forcing Load,

E : Emergency Shutdown ON,

G : Alarm Check,

H : Alarm Clear,

R, S : Run/Set Data read command

5) Extra2 R, S output command : Memory start address to save read value, Etc Output Command : Don't care

Write example 1)

Station : 1 Address : 0000 Extra1 : W, EXTRA2 : Blank

If you set as above and write digital value, you can ON compressor operation of no.1 S-TURBO Compressor device. (Any value do motion of compressor operation ON)

Write example 2)

Station : 1 Address : 0000 Extra1 : S, EXTRA2 : 300

If you set as above and write digital value, you can read Set Data of no.1 S-TURBO Compressor device and save from no.300 address of WORD/FLOAT/DWORD memory. (Save at memory no.300 to no.357 address)

RS-485 communication cable connection

Connect RS-485 communication cable to Port2(Under side) of <Figure 4>, as follows.

Computer side S-TURBO Compressor side

Tx+, Rx+ -------------------------------------- No.3 pin

Tx-, Rx- ---------------------------------------- No.2 pin

Notice) 4 wire RS-485 cable can be used according to S-TURBO Compressor device. ( 2 : Rx-, 3 : Rx+, 4 : Tx+, 5 : Tx- )

|

| <Figure 4> RS-485 communication port of S-TURBO Compressor controller |