STHC-MB is driver to communicate with thermo-hygrostat device of Seung IL Electronics, in Korea.

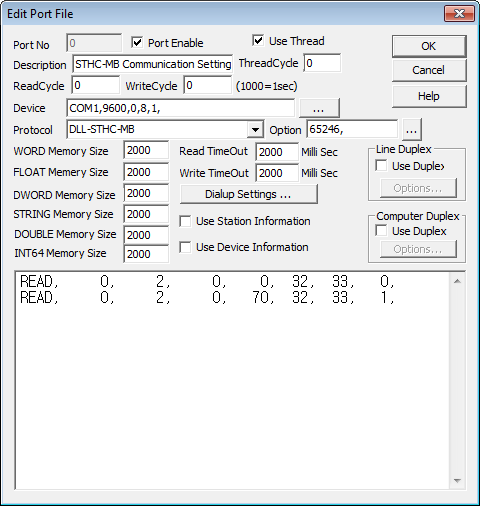

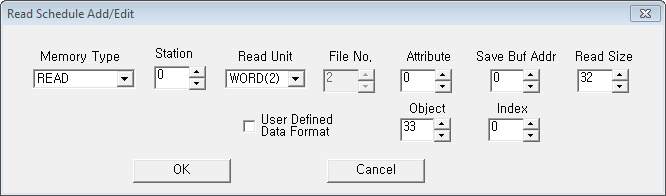

<Figure 1> is read setting example of STHC-MB communication driver.

|

| <Figure 1> Read setting example of STHC-MB driver |

Device part of <Figure 1> input Com Port(COM1), Baud Rate(9600), Parity Bit(0), Data Bit(8), Stop Bit(1) respectively, according to device.

Also, enter the Source Station (Device number of computer side, Default = 65246) at Option part.

STHC-MB communication driver's read schedule

Read schedule setting parameters are as follows :

1) STATION – Enter device number between 0 and 65535.

2) Read Command – Input as 2, 1 or 2.x, 1, x format. At this part, 2, 1 is data type(2 = WORD unit, 1 = BYTE unit),

x = File name of save method for read data,

2 ~ 255 : Set the save method for read data at WorkDirectory\SCAN\ReadInfo%03d.ini file. (Refer to <Table 3>)

3) Read Start Address – Read start Attribute number.

4) Save Start Address for Communication Server – Saving start address of Communication Server.

5) Read Size - Number of data to read. (WORD or BYTE unit)

6) Object number to read – Object number to read. (Default = 33 (21h) )

7) Index number to read - Index number to read. (Default = 0 )

Read schedule example)

READ, 0, 2, 0, 0, 32, 33, 0,

READ, 0, 2, 0, 70, 32, 33, 1,

<Table 1> is save address and contents of 33 Object, Index no.0 read of STHC-MB communication driver, and <Table 2> is save address and contents of read value for 33 Object, Index no.1 read.

Save Address of Communication Memory |

Save Contents |

Unit |

Remarks |

Save Addr + 0 |

Current Temp |

WORD |

Real value = Data x 0.1 |

Save Addr + 1 |

Temp Setting |

||

Save Addr + 2 |

Current Humidity |

BYTE |

|

Save Addr + 3 |

Humidity Setting |

||

Save Addr + 4 |

Cooling Deviation |

Real value = Data x 0.1 |

|

Save Addr + 5 |

Heating Deviation |

||

Save Addr + 6 |

Dehumidification Deviation |

||

Save Addr + 7 |

Humidification Deviation |

||

Save Addr + 8 ~ 10 |

Reserved |

||

Save Addr + 11 |

D/A Cooling Output |

||

Save Addr + 12 |

COMP Cycle |

0 : 1 cycle, 1 : 2 cycle, 2 : 3 cycle |

|

Save Addr + 13 |

Heater Step |

0 : 2 step, 1 : 3 step, 2 : 4 step, 3 : 5 step |

|

Save Addr + 14 |

Total RUN TIME |

WORD |

|

Save Addr + 15 |

Compressor 1 RUN TIM |

||

Save Addr + 16 |

Compressor 2 RUN TIME |

||

Save Addr + 17 |

Humidification Capacity |

BYTE |

|

Save Addr + 18 |

Humidification Voltage |

Real value = Data x 10 |

|

Save Addr + 19 |

Humidification Efficiency |

||

Save Addr + 20 |

BUZZER_OFF(CONTROL) |

||

Save Addr + 21 |

Rated Current |

WORD |

Real value = Data x 0.1 |

Save Addr + 22 |

Humidification Current |

||

Save Addr + 23 |

DEHUM ON/OFF |

BYTE |

0 : Stop, 1 : Run |

Save Addr + 24 |

HUM ON/OFF |

||

Save Addr + 25 |

HEAT ON/OFF |

||

Save Addr + 26 |

COOL ON/OFF |

||

Save Addr + 27 |

FAN ON/OFF |

||

Save Addr + 28 |

BUZZER_OFF(REMOT) |

||

Save Addr + 29 |

Low-pressure over 1 |

0 : Normal, 1 : Abnormality |

|

Save Addr + 30 |

Low-pressure over 2 |

||

Save Addr + 31 |

Water leak Occur |

||

Save Addr + 32 |

Main fan Abnormality |

||

Save Addr + 33 |

Air Water Flow Abnormality |

||

Save Addr + 34 |

Heating Heater Abnormality |

||

Save Addr + 35 |

Humidity Heater Abnormality |

||

Save Addr + 36 |

Compressor 2 Abnormality |

||

Save Addr + 37 |

Compressor 1 Abnormality |

||

Save Addr + 38 |

Humidity High Humidity Abnormality |

||

Save Addr + 39 |

Temp High Temp Abnormality |

||

Save Addr + 40 |

Water supply Abnormality |

||

Save Addr + 41 |

Over-current Occur |

||

Save Addr + 42 |

Drainage Abnormality |

||

Save Addr + 43 |

Forced Drainage |

|

0 : OFF, 1 : ON |

Save Addr + 44 |

Reserved |

||

Save Addr + 45 |

Humidity Control |

0 : OFF, 1 : ON |

|

Save Addr + 46 |

Run Mode |

0 : Itself, 1 : Remote |

|

Save Addr + 47 |

Dehumidification Run |

0 : OFF, 1 : ON |

|

Save Addr + 48 |

Humidification Method |

0 : Electrode bar, 1 : PAN, 2 : Evaporation |

|

Save Addr + 49 |

Heater Rotation |

0 : OFF, 1 : ON |

|

Save Addr + 50 |

Reserved |

||

Save Addr + 51 |

Run time of Humidifier |

WORD |

|

Save Addr + 52 |

Cooling Humidification |

BYTE |

0 : OFF, 1 : ON |

Save Addr + 53 |

D/A Output Setting |

|

|

Save Addr + 54 |

Run ON/OFF |

0 : Stop, 1 : Run |

|

Save Addr + 55 |

TOTAL ALARM |

0 : Normal, 1 : Abnormality |

|

| <Table 1> Save address and contents of read value for 33 Object, Index no.0(Attribute = 0) read of STHC-MB communication driver | |||

| Save Address of Communication Memory | Save Contents |

Unit |

Remarks |

Save Addr + 0 ~ 4 |

Reserved |

WORD |

|

Save Addr + 5 |

Water supply time Setting |

BYTE |

|

Save Addr + 6 |

Drainage time Setting |

||

Save Addr + 7 |

HUM2_RUN Status |

0 : Stop, 1 : Run |

|

Save Addr + 8 |

HUM2_SOL Status |

||

Save Addr + 9 ~ 10 |

Reserved |

||

Save Addr + 11 |

Compressor 1 Delay time |

WORD |

|

Save Addr + 12 |

Compressor 2 Delay time |

||

Save Addr + 13 |

Fan motor Delay |

||

Save Addr + 14 |

Temp Correction |

BYTE |

Real value = ( Data - 100 ) x 0.1 |

Save Addr + 15 |

Humidity Correction |

Real value = Data – 20 |

|

Save Addr + 16 |

CT Correction |

Real value = ( Data - 50 ) x 0.1 |

|

Save Addr + 17 |

LEAK Mode |

0 : OFF, 1 : ON |

|

Save Addr + 18 |

Blackout Return time |

WORD |

|

Save Addr + 19 |

DA/Temp |

BYTE |

|

Save Addr + 20 |

DA/Humidity |

||

Save Addr + 21 |

DA/Heating Deviation |

||

Save Addr + 22 |

DA/Cooling Deviation |

||

Save Addr + 23 |

DA/Humidification Deviation |

||

Save Addr + 24 |

DA/Dehumidification Deviation |

||

Save Addr + 25 |

DA/Cooling Dehumidification |

||

Save Addr + 26 |

DA/ CT |

||

Save Addr + 27 ~ 50 |

Reserved |

||

Save Addr + 51 |

Input Status |

0:C/O1, 1:L/P1, 2: C/O2, 3:L/P2 4:HU/OT, 5:H/OT, 6:AFS, 7: BWR/O, |

|

8:REMOT, 9: LEAK, A: W/L1, B:WL/2, C: C/O3, D:L/P3, E: W-SEN, F: HALON |

|||

Save Addr + 52 |

Output Status |

0: SSR, 1: H1, 2: H2, 3: H3, 4:H4, 5:COMP1, 6: COMP2, 7:COMP3, |

|

8: SOL1, 9: SOL2, A: BWR, B: ALM, C: HU2, D: HU1, E: HU/SOL, F: SOL3 |

|||

| <Table 2> Save address and contents of read value for 33 Object, Index no.1(Attribute = 0) read of STHC-MB communication driver | |||

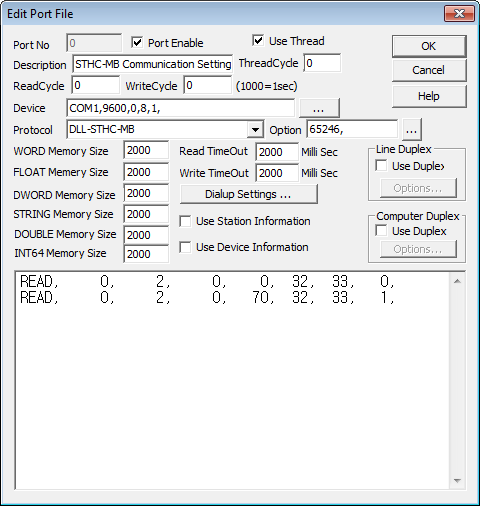

File Name |

ini File Writing method |

WorkDirectory\SCAN\ReadInfo%03d.ini

At this sentence, %03d is setting data number between 2 and 255. |

1) Write as text to first line of file. 2) Classify each factor as ','(comma). 3) Write the maximum 256 data save methods. 4) Enter B = Byte, W = Word, W2 = Word HI LO by classifying as comma. |

| <Table 3> ini file writing method for saving read data | |

|

| <Figure 2> Example of writing ini file for saving read data |

Read value of STHC-MB communication driver is saved as same value(just save format is different) to WORD/DWORD/FLOAT memory.

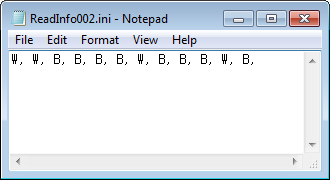

If you click the icon ![]() in protocol option

part of <Figure 1>, you can see the dialog box such as <Figure 3>. You can

also set read schedule by using this part.

in protocol option

part of <Figure 1>, you can see the dialog box such as <Figure 3>. You can

also set read schedule by using this part.

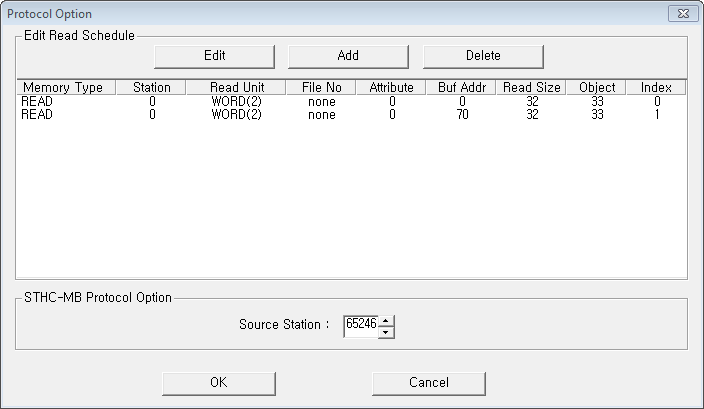

|

| <Figure 3> Example of STHC-MB driver's Option dialog box |

You can set read schedule by using ![]() ,

, ![]() ,

, ![]() button and listbox

of <Figure 3>.

button and listbox

of <Figure 3>.

Also, you can set Source Station (device number of computer side) at 'Source Station' area of <Figure 3>.

|

| <Figure 4> STHC-MB driver's read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialog box of <Figure 3>, dialog box of <Figure 4> is shown.

You can change setting value by using writing setting of STHC-MB communication driver.

Digital Write

Digital write and analog write have the same setting parameters except output value(0 or 1).

Analog Write

Analog write setting parameters are as follows:

1) PORT Connected communication port number. (Not COM number)

2) STATION Enter device number between 0 and 65535.

3) ADDRESS Index number to output. (Refer to <Table 4>)

4) Extra1 Enter Object number. In case of not input, it is 16(10h) Object.

5) Extra2 1 = Writing BYTE unit data,

0 = Writing WORD unit data(default).

<Table 4> is output value setting range by Address(Index) of no.16 Object writing for STHC-MB communication driver.

| ADDRESS Number | Output Contents |

Output Range |

Remarks |

| 0 | Temp Setting |

0 ~ 600 |

Output value = Real value x 10 |

| 1 | Humidity Setting |

1 ~ 99 |

|

| 2 | Cooling Deviation Setting |

1 ~ 150 |

Output value = Real value x 10 |

| 3 | Heating Deviation Setting |

||

| 4 | Dehumidification Deviation Setting |

1 ~ 50 |

|

| 5 | Compressor Delay 3 |

0 ~ 600 |

|

| 6 | Compressor Delay 4 |

||

| 7 | Humidification Deviation |

1 ~ 50 |

|

| 8 | Compressor Delay 1 |

0 ~ 600 |

|

| 9 | Compressor Delay 2 |

||

| 10 | FAN Motor Delay |

||

| 11 | COMP Cycle |

0 : 1 cycle, 1 : 2 cycle, 2 : 3 cycle |

|

| 12 | Heater Step |

0 ~ 5 |

|

| 13 | Humidification Capacity |

1 ~ 45 |

|

| 14 | Humidification Voltage |

20 ~ 50 |

Output value = Real value / 10 |

| 15 | Humidification Efficiency |

10 ~ 120 |

|

| 16 | BUZZER_OFF(REMOT) |

0 ~ 1 |

|

| 17 | Forced Drainage |

0 : OFF, 1 : ON |

|

| 18 | Blackout Return |

0 ~ 600 |

|

| 19 | Humidity Control |

0 : OFF, 1 : ON |

|

| 20 | Run Mode |

0 : Itself, 1 : Remote |

|

| 21 | Dehumidification Run |

0 : OFF, 1 : ON |

|

| 22 | Humidification Method |

0 : Electrode bar, 1 : PAN, 2 : Evaporation |

|

| 23 | Heater Rotation |

0 ~ 1 |

|

| 24 | System Initialization |

0 : OFF, 1 : Initialization |

|

| 25 | Cooling Humidification |

0 : OFF, 1 : ON |

|

| 26 | D/A Output Setting |

0 ~ 11 |

|

| 27 | Run ON/OFF |

0 : Stop |

|

| 28 | Temp Correction |

1 ~ 199 Output value = (Real value + 100 ) x 10 |

Have to output after calculating LOW, HIGH byte |

Humidity Correction |

1 ~ 39 Output value = Real value + 20 |

||

| 29 | CT Correction |

1 ~ 99 Output value = (Real value + 50 ) x 10 |

|

LEAK Mode |

0 : OFF, 1 : ON |

||

| <Table 4> Output value setting range by Address(Index) of no.16 Object writing for STHC-MB communication driver | |||

Write example 1)

PORT : 0 STATION : 0 ADDRESS : 0000 EXTRA1 : 16 EXTRA2 : 0

If you set as above and analog output, you can change temperature setting value of no.0 STHC-MB device connected with no.0 port.

Write example 2)

PORT : 0 STATION : 0 ADDRESS : 0001 EXTRA1 : 16 EXTRA2 : 0

If you set as above and analog output, you can change humidity setting value of no.0 STHC-MB device connected with no.0 port.

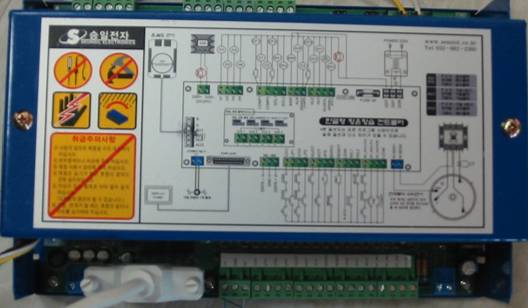

Connect communication cable with basic power of STHC-MB device as follows.

Communication cable

Connect Tx, Rx of computer side to RS-485 Tx, Rx terminal of STHC-MB device such as <Figure 5>.

|

| <Figure 5> Appearance of connecting communication cable and basic power etc to STHC-MB device |

Basic power connection

Connect basic power to power input part of STHC-MB device, such as <Figure 5>.

<Figure 6> is console of STHC-MB.

|

| <Figure 6> Console of STHC-MB |