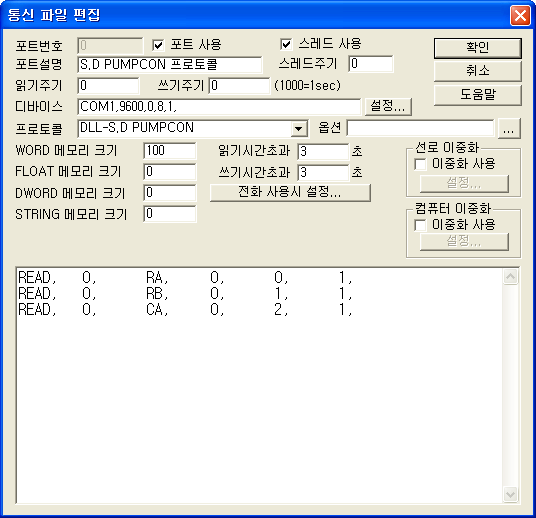

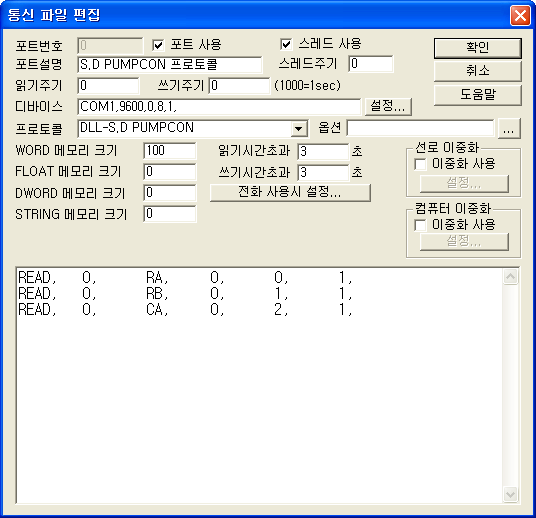

<Figure 1> is read setting example of S.D PUMPCON communication driver which is pump controller of S.D Engineering Co.

|

| <Figure 1> Read setting example of S.D PUMPCON communication driver |

Communication speed(Com Baud) and etc of DEVICE settings are fixed as 9600, 0, 8, 1,.

| READ | STATION(Don't care) | Read Type | Read Start Address(Don't care) | Save Start Address for Communication Server | Read Size |

| READ, | 0, | RA, | 0, | 0, | 1, |

| READ, | 0, | RB, | 0, | 1, | 1, |

| READ, | 0, | CA, | 0, | 2, | 1, |

1) Read Type : COMMAND area(RA, RB, RC, RD0~RD6 etc) used at PUMPCON. Refer to <Table 1>, for more detail.

2) Save Start Address for Communication Server : ScanBuf position to save the read status value.

3) Read Size : The number of items to read at a time. (Size is fixed according to type to read. Refer to <Table 1>)

Read schedule example)

READ, 0, RA, 0, 0, 1,

READ, 0, RB, 0, 1, 1,

READ, 0, CA, 0, 2, 1,

As you see above, STATION wasn't used. In case of 485 communication, you must use 1:1 communication.

Area which can be used in S.D PUMPCOM

| Area | Area Description | Read Size | Buf Description |

Read/Write | Remarks |

| RA | Operation Pressure | 1 |

|

Read only | 1/10 Bar |

| RB | Inverter Output | 1 |

|

Read only | % |

| RC | Current Status for Operation Pump | 1 |

|

Read only | |

| RD0 | Pump Operation Data 0 | 2 | BUF+0 = Operation Time BUF+1 = Number of Operating |

Read only | |

| RD1 | Pump Operation Data 1 | 2 | BUF+0 = Operation Time BUF+1 = Number of Operating |

Read only | |

| RD2 | Pump Operation Data 2 | 2 | BUF+0 = Operation Time BUF+1 = Number of Operating |

Read only | |

| RD3 | Pump Operation Data 3 | 2 | BUF+0 = Operation Time BUF+1 = Number of Operating |

Read only | |

| RD4 | Pump Operation Data 4 | 2 | BUF+0 = Operation Time BUF+1 = Number of Operating |

Read only | |

| RD5 | Pump Operation Data 5 | 2 | BUF+0 = Operation Time BUF+1 = Number of Operating |

Read only | |

| RD6 | Pump Operation Data 6 | 2 | BUF+0 = Operation Time BUF+1 = Number of Operating |

Read only | |

| RE00 | Number of Malfunction | 1 |

|

Read only | |

| RE01

... ... ... ... RE20 |

Contents of Malfunction 00 ... ... ... Contents of Malfunction 20 |

9 | BUF+0 = Error Code BUF+1 = Year BUF+2 = Month BUF+3 = Day BUF+4 = Hour BUF+5 = Min BUF+6= Operation Pressure BUF+7 = Output(%) BUF+8 = Start Pump |

Read only | |

| WA | Operation/Stop |

|

Write only | 0 OR 1 | |

| WB | Delete Contents of Malfunction |

|

Write only | ||

| WC | System Initialization |

|

Write only | ||

| CA | Set Pressure | 1 | 000~999 |

Read/Write | 1/10 Bar |

| CB | Current Time | 7 | BUF+0 = Year BUF+1 = Month BUF+2 = Day BUF+3 = Hour BUF+4 = Min BUF+5 = Sec BUF+6 = Day of Week |

Read/Write | |

| CC | Select Method of Operation Control | 1 | 1 OR 0 |

Read/Write | 1 = Inverter 0 = Number |

| CD | Change Method of Operation Control | 1 | 1 OR 0 |

Read/Write | 1 = Auto 0 = Manual |

| CE | Register Operation Pump | 1 | 111000 format |

Read/Write | 1 = ON 0 = OFF |

| CF | Rotation Operating Cycle | 1 | 0000~9999 |

||

| CG | Select Start Pump | 1 | 1~6 |

||

| CH | Return to Operation After Power Outage | 1 | 1 OR 0 |

Read/Write | 1 = Auto 0 = Manual |

| CI | Return to Operation by Low Water Level | 1 | 1 OR 0 |

Read/Write | 1 = Auto 0 = Manual |

| CJ | Alarm for Maximum Pressure | 1 | 000~999 |

Read/Write | |

| CK | Alarm for Minimum Pressure | 2 | BUF+0 = Pressure BUF+1 = CH |

Read/Write | |

| CL | Pressure Sensor Type | 1 | 0 OR 1 |

Read/Write | 1 = 10 0 = 20 |

| CM | Adjust Sensor Zero Point | 1 | -99~+99 |

Read/Write | 1/10 BAR |

| CN | Delay Time for Number Increase | 1 | 000~999 |

Read/Write | Sec |

| CO | Delay Time for Number Decrease | 1 | 000~999 |

Read/Write | Sec |

| CP | Minimum Operating Time of Pump | 1 | 000~999 |

Read/Write | Sec |

| CQ | Low Water Level Detection Delayed | 1 | 000~999 |

Read/Write | Sec |

| CR | Re-Operation Down-Time | 1 | 000~999 |

Read/Write | Sec |

| CS | Down-Time between Pump | 1 | 000~999 |

Read/Write | Sec |

| <Table 1> S.D PUMPCON communication driver's description by area | |||||

Reference : Way to see Table - You can't read what was written as 'Write only', at above table. Also, 'Read only' means that data can't be written at controller. Because there is area more than above table, in reality, refer to controller manual for more details.

Write to direct ADDRESS of controller, regardless of SCAN File.

Digital Write

Digital Write means that ON/OFF the point of contact of controller. "1 OR 0" area of buf descriptions in <Table 1> can do digital write.

Digital write setting parameters are as follows :

1) PORT Connected PORT number

2) ADDRESS Address which want to output, It is used when several items are in same area.

3) Extra1 Memory area which want to output

Write example 1)

Address:0000, Extra1:WA

If you set as above and write digital value, you can output operate/stop the controller. Also, if you output ADDRESS from 0 to 5 in order by using CE command(register operation pump), 6 pumps are registered.

Analog Write

Analog Write means that write WORD value to controller.

Analog write setting parameters are as follows:

1) PORT Connected PORT number

2) ADDRESS Address which want to output,

3) Extra1 Memory area which want to output Possible to write to WORD. Area which is shown at <Table 1>.

Write example 1)

ADDRESS:0000, EXTRA1:CA

If you set as above and write analog value, you can change setting pressure value. It can't output at a time such as CB, so, if you want to output several data at a time, you have to command ADDRESS : 0007 after outputting ADDRESS : 0000 ~0006 in order, then accumulated data are output.