X8 PLC Xnet Protocol is the driver to communicate with X8 Series PLC of RS Automation in Korea.

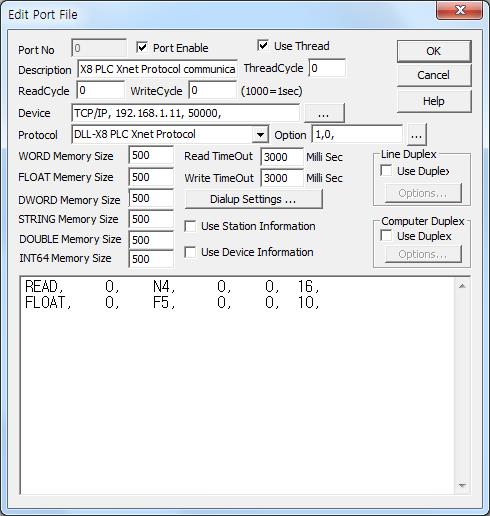

<Figure 1> is read setting example of X8 PLC Xnet Protocol communication driver.

|

| <Figure 1> Read setting example of X8 PLC Xnet Protocol communication driver |

Device part of <Figure 1> input device type(TCP/IP), ip address of PLC(192.168.1.11), service port number of TCP/IP(50000), accordint to the setting of controller.

Also, you can set whether to use of Ethernet module( 0 : don't use(serial), 1 : use, default = 1), node number of computer(0 ~ 249, default = 0) by using option part (separated by commas each parameter).

Read schedule of X8 PLC Xnet Protocol communication driver

Read schedule setting parameters are as follows:

1) Station – 0 ~ 249 node number when using serial module. ( Ethernet module : fixed to 254 )

2) Read command – X, Y, SR, B, N, F, L, A, ST, TM, CT, CR Data Table type and 3 ~ 1535( X, Y, SR : don't use) Table number. ( refer to <Table 1> )

3) Read start address – 0 ~ 1535 Table Element number. ( X, Y = 0 ~ 96, ST = 0 ~ 779)

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read size – read size by Table type ( word, double word, float, string, etc unit )

X, Y, SR, B, N, A = 1 ~ 111,

F, L = 1 ~ 55,

ST = 1 ~ 2,

TM, CT, CR = 1 ~ 22.

6) Extra2 – Sub-Element address when X, Y, F, L, ST, TM, CT CR Table type.

Read schedule example)

READ, 0, N4, 0, 0, 16,

FLOAT, 0, F5, 0, 0, 10,

<Table 1> is Table name/number and Element address of X8 PLC Xnet PLC.

Read command |

Contents |

Element address | Sub-Element address | Words of per Element | Remarsk |

|

| Table name | Table number | |||||

X |

0 (fixed) | Inputs(slot) |

0 ~ 96 | 0 ~ 511 (word offset) | 1 | You can set Table number, Element size at PLC Ladder program |

Y |

1 (fixed) | Outputs(slot) |

0 ~ 96 | 0 ~ 511 (word offset) | 1 | |

SR |

2 (fixed) | System Register |

0 ~ 127 | 0 (fixed) | 1 | |

B |

3 ~ 1535 | Binary |

0 ~ 1535 | 0 (fixed) | 1 | |

N |

3 ~ 1535 | Integer |

0 ~ 1535 | 0 (fixed) | 1 | |

F |

3 ~ 1535 | Floating Point |

0 ~ 1535 | 0 ~ 1 | 2 | |

L |

3 ~ 1535 | Long |

0 ~ 1535 | 0 ~ 1 | 2 | |

A |

3 ~ 1535 | ASCII |

0 ~ 1535 | 0 (fixed) | 1 | |

ST |

3 ~ 1535 | String |

0 ~ 779 | 0 ~ 41 | 42 | |

TM |

3 ~ 1535 | Timer |

0 ~ 1535 | 0 ~ 4 | 5 | |

CT |

3 ~ 1535 | Counter |

0 ~ 1535 | 0 ~ 4 | 5 | |

CR |

3 ~ 1535 | Control |

0 ~ 1535 | 0 ~ 4 | 5 | |

| <Table 1> Table name/number and Element address of X8 PLC Xnet PLC | ||||||

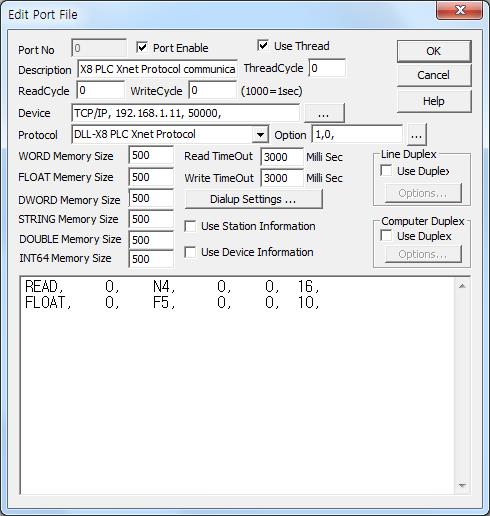

If you click the icon ![]() in protocol option part at

<Figure 1>, you

can see the dialog box such as <Figure 2>. you can also set read schedule by

using this part.

in protocol option part at

<Figure 1>, you

can see the dialog box such as <Figure 2>. you can also set read schedule by

using this part.

|

|

<Figure 2> Example of X8 PLC Xnet Protocol communication driverí»s Option dialog box |

You can set read schedule by using

![]() ,

,

![]() ,

,

![]() button and listbox of <Figure

2>.

button and listbox of <Figure

2>.

Whether to use of Ethernet module and node number of computer can set by using of Protocol Option part in <Figure 2>.

|

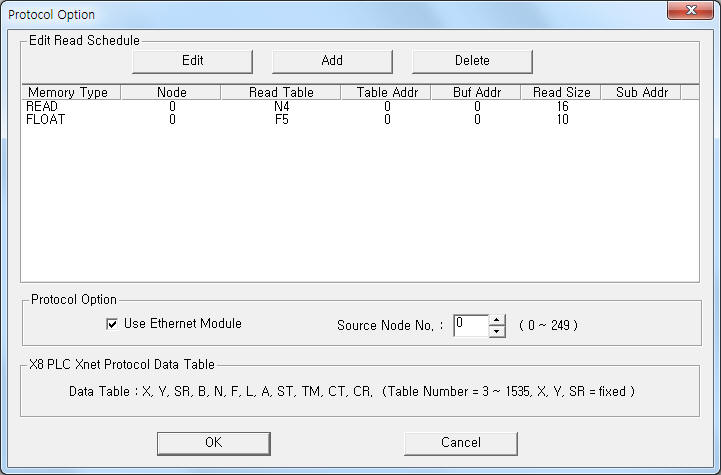

| <Figure 3> Example of X8 PLC Xnet Protocol communication driverí»s read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialogue box of <Figure 2>, dialogue box of <Figure 3> is shown.

You can set X8 PLC by using 'write settings'.

Digital Write

Digital write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION 0 ~ 249 node number when using serial module. ( Ethernet module : fixed to 254 )

3) ADDRESS writing Element address.

lower 1 digit : 0 ~ F bit position,

higher 3 ~ 7 digit : 0 ~ 1535 Table Element number. ( X, Y = 0 ~ 96, ST = 0 ~ 779)

4) Extra1 write command = X, Y, SR, B, N, F, L, A, ST, TM, CT, CR Data Table type and 3 ~ 1535( X, Y, SR : don't use) Table number. ( refer to <Table 1> )

when the table type is ST, write command format = ST??.xxx. ?? = Table number, xxx = string to be written.

5) Extra2 Sub-Element address when X, Y, F, L, ST, TM, CT CR Table type.

Write example 1)

PORT : 0 STATION : 0 ADDRESS : 005F EXTRA1 : B3 EXTRA2 : 0

The setting parameter shown above is B3 Table, 5 Element number, F bit control(On/Off) example of X8 PLC.

Write example 2)

PORT : 0 STATION : 0 ADDRESS : 0127 EXTRA1 : B3 EXTRA2 : 0

The setting parameter shown above is B3 Table, 12 Element number, 7 bit control(On/Off) example of X8 PLC.

Analog Write

Analog write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION 0 ~ 249 node number when using serial module. ( Ethernet module : fixed to 254 )

3) ADDRESS 0 ~ 1535 Table Element number. ( X, Y = 0 ~ 96, ST = 0 ~ 779)

4) Extra1 write command = X, Y, SR, B, N, F, L, A, ST, TM, CT, CR Data Table type and 3 ~ 1535( X, Y, SR : don't use) Table number. ( refer to <Table 1> )

when the table type is ST, write command format = ST??.xxx. ?? = Table number, xxx = string to be written.

5) Extra2 Sub-Element address when X, Y, F, L, ST, TM, CT CR Table type.

Write example 1)

PORT : 0 STATION : 0 ADDRESS : 0016 EXTRA1 : N4 EXTRA2 : 0

The setting parameter shown above is N4 Table, 16 Element number WORD unit setting example of X8 PLC.

Write example 2)

PORT : 0 STATION : 0 ADDRESS : 0008 EXTRA1 : F5 EXTRA2 : 0

The setting parameter shown above is F5 Table, 8 Element number Float unit setting example of X8 PLC.

Block Write

Block write use PlcScanWriteBlock script such as follows.

script function and parameters : @PlcScanWriteBlock(int port, int station, int address, string extra1, string extra2, object array_value, int array_size);

Block write script example 1 ( N4 Block Write )

ushort Val[10];

Val[0] = 25;

Val[1] = 55;

Val[2] = 31;

Val[3] = 2347;

Val[4] = 3869;

Val[5] = 5;

Val[6] = 72;

Val[7] = 32756;

Val[8] = 541;

Val[9] = 8845;

@PlcScanWriteBlock(0, 0, 0, "N4", 0,

Val, 10);

Block write script example 1 ( F5 Block Write )

float Val[10];

Val[0] = 12286.2;

Val[1] = 255.5;

Val[2] = 32.45;

Val[3]

= 400.567;

Val[4] = 65.12;

Val[5] = 1026.9;

Val[6] = 327.1;

Val[7] =

3.5;

Val[8] = 4.9;

Val[9] = 91.56;

@PlcScanWriteBlock(0, 0, 0, "F5", 0, Val,

10);

Block write script example 1 ( ST8 Block Write )

string str;

@sprintf(str,"abcdefghijklmnopqrstuvwxyz0123456789ABCDEFGHIJKLMNOPQRSTUVWXYZ0123456789");

@PlcScanWriteBlock(0, 0, 0, "ST8", 0, str, 72);

<Figure 4> shows the appearance of X8 PLC.

|

| <Figure 4> Appearance of X8 PLC |