PCD S-BUS communication driver is the driver to communicate with S-BUS protocol of Saia-Burgess Controls in Switzerland.

Note) PCD controller have 2 Protocol, P8 and S-BUS. PCD S-BUS communication driver use S-BUS protocol.

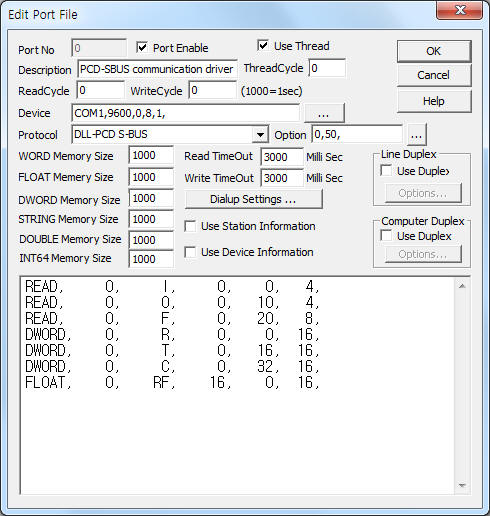

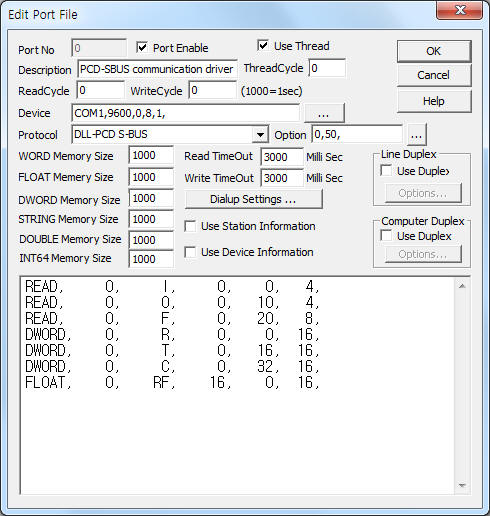

<Figure 1> is read setting example of PCD S-BUS communication driver.

|

| <Figure 1> Read setting example of PCD S-BUS communication driver |

Device part of <Figure 1> input Com Port(COM1), Baud Rate(9600), Parity Bit(0), Data Bit(8), Stop Bit(1) respectively, according tosetting of controller.

In protocol option, you can set 'protocol type of S-BUS'( 0 : Data Mode, 1 : Parity Mode, 2 : Break Mode, default = 0 ), 'delay time when Parity/Break communication mode'( 1 ~ 100 milli second, default = 30 ). Each argument is a comma-delimited.

Note) Baud rate, parity bit, data bit, stop bit of S-BUS protocol can set 'Setup' program such as 'Chapter 4'.

PCD S-BUS communication driver¡¯s read schedule

Read schedule setting parameters are as follows:

1) Station – PCD station number = 0 ~ 254.

2) Read data type – data type = I,O,F,R, RF,T,C. ( refer to <Table 1> )

3) Read Start Address – reading start address in data type.

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read Size – word or double word / float unit read size.

I,O,F : 1 ~ 16 word ( 16bit unit ),

R,T,C : 1~32 double word or float.

Read schedule example)

READ, 0, I, 0, 0, 4,

READ, 0, O, 0, 10, 4,

READ, 0, F, 0, 20, 8,

DWORD, 0, R, 0, 0, 16,

DWORD, 0, T, 0, 16, 16,

DWORD, 0, C, 0, 32, 16,

FLOAT, 0, RF, 16, 0, 16,

<Table 1> is data type and contents of PCD controller.

Data(memory) type |

Contents |

Units |

Write |

I |

Input |

Bit |

disable |

O |

Output |

enable |

|

F |

Flag |

||

R/RF |

Register |

R = DWORD, RF = FLOAT |

|

T |

Timer |

DWORD |

|

C |

Counter |

DWORD |

|

| <Table 1> Data type and contents of PCD controller | |||

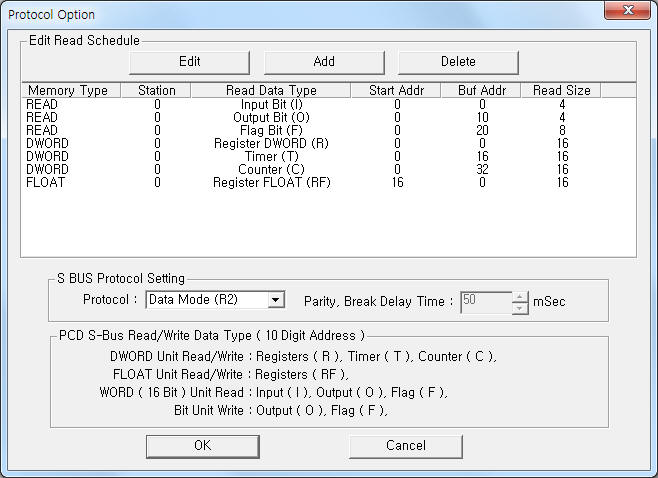

If you click the icon ![]() in protocol option part, you

can see the dialog box such as <Figure 2>. you can also set read schedule by

using this part.

in protocol option part, you

can see the dialog box such as <Figure 2>. you can also set read schedule by

using this part.

|

| <Figure 2> Example of PCD S-BUS communication driver¡¯s Option dialog box |

You can set read schedule by using ![]() ,

, ![]() ,

, ![]() button and listbox of <Figure

2>.

button and listbox of <Figure

2>.

Also, you can set protocol type of S-BUS, delay time when Parity/Break communication mode by using the part of ¡®S-BUS protocol Setting¡¯ shown in <Figure 2>.

|

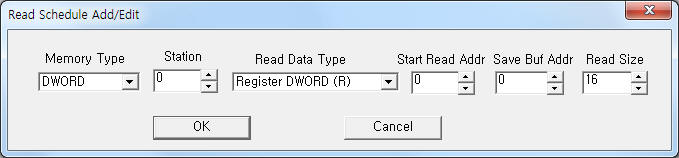

| <Figure 3> Example of PCD S-BUS communication driver¡¯s read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialog box of <Figure 2>, dialog box of <Figure 3> is shown.

You can control PCD controller by using 'write settings'.

Digital Write

Digital write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION PCD station number = 0 ~ 254.

3) ADDRESS writing address in data type. ( decimal unit including bit, double word data type )

4) Extra1 write data type = O, F, R, RF, T, C.

5) Extra2 don't care.

Write example 1)

PORT : 0 , STATION : 0, ADDRESS : 0015, EXTRA1 : O, EXTRA2 :

The setting parameter shown above is control( On/Off ) example of O0015 address.

Write example 2)

PORT : 0 , STATION : 0, ADDRESS : 0021, EXTRA1 : F, EXTRA2 :

The setting parameter shown above is control( On/Off ) example of F0021 address.

Analog Write

Analog write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION PCD station number = 0 ~ 254.

3) ADDRESS writing address in data type. ( decimal unit including bit, double word data type )

4) Extra1 write data type = R, RF, T, C, O, F.

5) Extra2 don't care.

Write example 1)

PORT : 0 , STATION : 0, ADDRESS : 0003, EXTRA1 : R, EXTRA2 :

The setting parameter shown above is dobule word unit write setting example of R0003 address.

Write example 2)

PORT : 0 , STATION : 0, ADDRESS : 0012, EXTRA1 : RF, EXTRA2 :

The setting parameter shown above is float unit write setting example of R0012 address.

Write example 3)

PORT : 0 , STATION : 0, ADDRESS : 0035, EXTRA1 : T, EXTRA2 :

The setting parameter shown above is double word unit write setting example of T0035 address.

Connection of power and communication cable are as follows.

Connection of main power

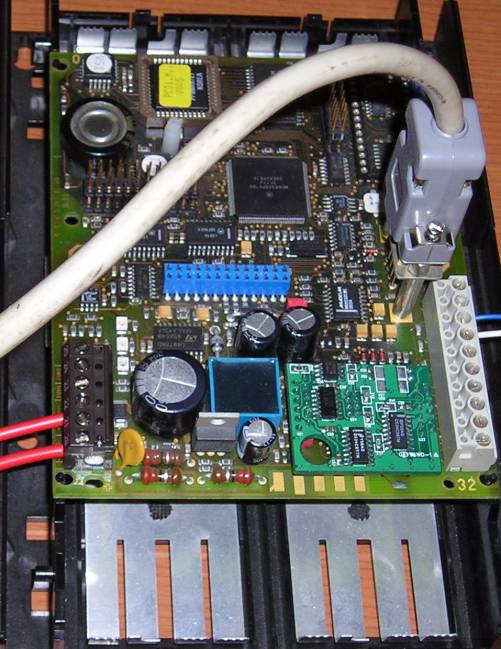

Please connect 24V DC power to main power connector such as <Figure 4>.

Connect 1st, 2nd pin = +24 V ( 20, 21 two or one ), 3rd, 4th pin = 0 V ( 22, 23 two or one ) from below of main power connector( black socket ).

|

| <Figure 4> Connection example of main power line and communication cable to PCD controller |

<Figure 5> shows the appearance of PCD controller.

|

| <Figure 5> Appearance of PCD controller |

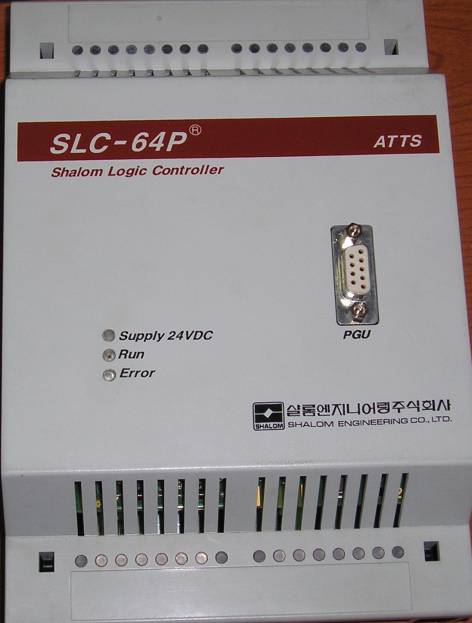

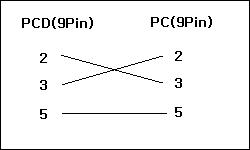

Connection of RS-232C communication cable

Please connect RS-232C communication cable to 9pin connector such as <Figure 6>.

|

| <Figure 6> Wiring diagram of RS-232C communication cable for PCD controller |

Note) You can't use RS-232C communication cable for P8 protocol at S-BUS protocol( communication driver ).

Connection of RS-485 communication cable

Please connect RS-485 communication cable to 2( +, 3rd ), 1 ( -, 2nd ) pin such as <Figure 7>.

RS-485 of computer socket of PCD controller

+ connector ----------------------------------- 2 pin

- connector ----------------------------------- 1 pin

<Figure 7> Wiring diagram of RS-485 communication cable for PCD controller

Normally, for communicating with computer, you should to install RS-485 communication card or RS-232C to RS-485 Converter at computer.

<Figure 8> is wiring diagram of PCD7.T 120 RS-232C/RS-485 Converter.

|

| <Figure 8> Wiring diagram of PCD7.T 120 RS-232C/RS-485 Converter |

When you using PCD7.T 120 RS-232C/RS-485 Converter, you should to set 'TxRTS' and 'RTS Delay Time' for Read, Write.

So, we don't recommend PCD7.T 120 RS-232C/RS-485 Converter.

Settings of PCD S-BUS communication are as follows :

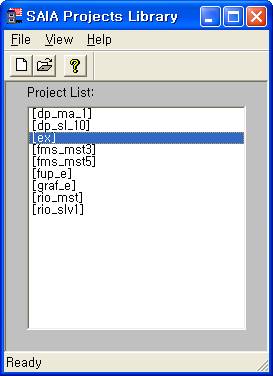

1) Please run 'SAIA Projects Library' program such as <Figure 9>.

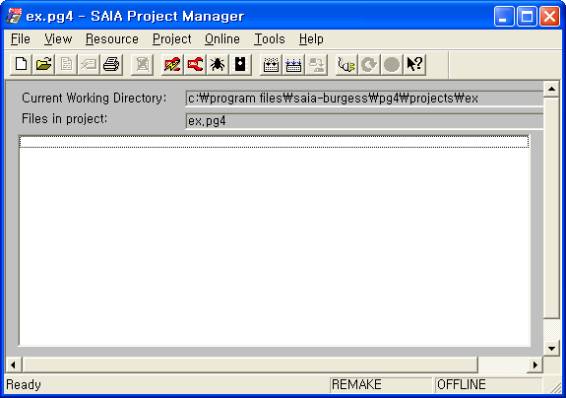

2) Make new project or select old project at <Figure 9>. Select ¡®Edit Project¡¯ menu( double click, ... ). Then, will be open 'Project Manager' such as <Figure 10>.

|

| <Figure 9> Example of 'SAIA Projects Library' |

|

| <Figure 10> Example of 'SAIA Project Manager' |

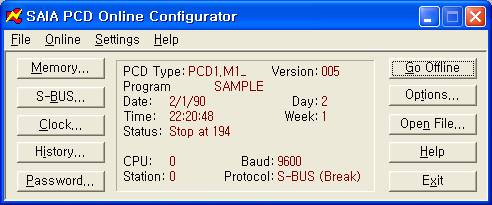

3) Please select ¡®Tools | PCD Online Configurator¡¯ menu at <Figure 10>. Then, will be open 'PCD Online Configurator' such as <Figure 11>.

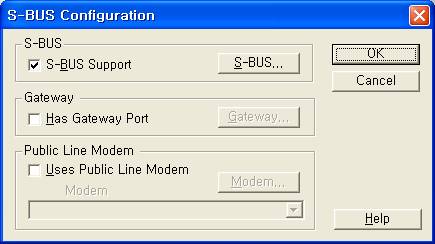

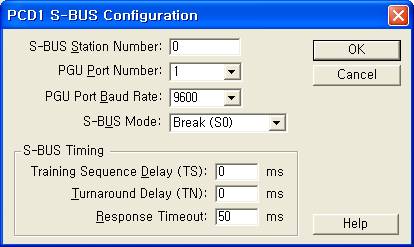

4) When you click ¡®S-BUS¡¯ button at <Figure 11>, will be open <Figure 12> dialog box.

5) If 'S-BUS' button is disabled, please select ¡®Options¡¦¡¯ button. Also, set Com port, baud rate, station number, ... and select ¡®Go Online¡¯ button. ( then , will be change to 'Online' )

6) Press ¡®S-BUS¡¦¡¯ button at <Figure 12>. Then, will be open 'PCD1 S-BUS Configuration' dialog box such as <Figure 13>.

7) You can set station number, baud rate, type of protocol at <Figure 13>.

|

| <Figure 11> Example of 'SAIA PCD Online Configurator' |

|

| <Figure 12> Example of 'S-BUS Configuration' |

|

| <Figure 13> Example of 'PCD1 S-BUS Configuration' |

Note) You can change one item at a time by using 'PCD1 S-BUS Configuration' such as<Figure 13>.

So, you have to another set after one item changing for another configuration.