M-BUS( Meter-BUS ) for Relay Etc communication driver is the driver to communicate with Heat Meter, Sensor, ... of Relay GmbH in Germany.

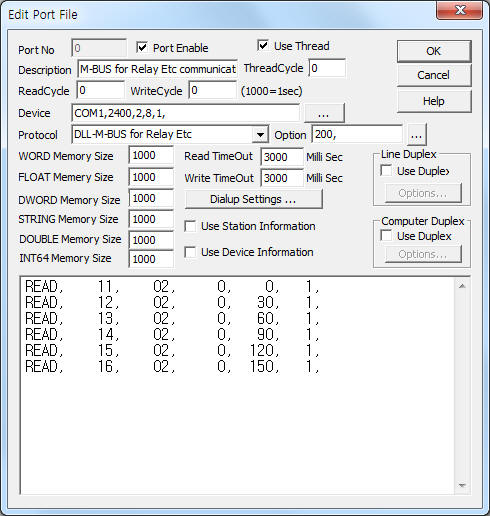

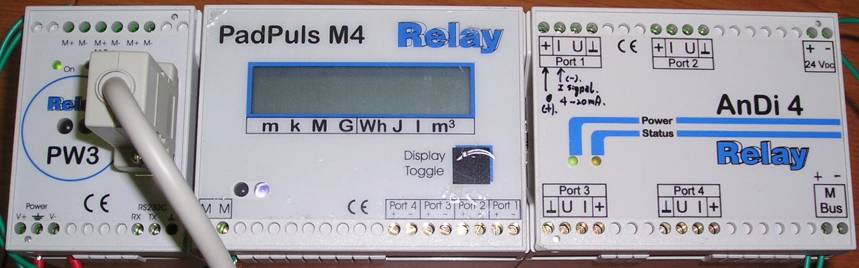

<Figure 1> is read setting example of M-BUS for Relay Etc communication driver.

|

| <Figure 1> Read setting example of M-BUS for Relay Etc communication driver |

Device part of <Figure 1> input Com Port(COM1), Baud Rate(2400), Parity Bit(2), Data Bit(8), Stop Bit(1) respectively, according to controller.

In protocol option part, you can set Write after waiting time(0 ~ 2000 mSec, Default = 200).

M-BUS for Relay Etc communication driver read schedule

Read schedule setting parameters are as follows:

1) Station – 0 ~ 254 station address.

2) Read command – command = fixed to 02. ( read od class 2 data )

3) Read start address – don't care.

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read Size – fixed to 1.

Note) Data type, size, contents of Class 2 vary according to equipment.

Read schedule example)

READ, 11, 02, 0, 0, 1,

READ, 12, 02, 0, 30, 1,

READ, 13, 02, 0, 60, 1,

READ, 14, 02, 0, 90, 1,

READ, 15, 02, 0, 120, 1,

READ, 16, 02, 0, 150, 1,

<Table 1> is data saving address and contents for class 2 data. <Table 2> is Fixed/Variable Data according to Medium.

| Data saving address | Contents | Rnage |

| Start address + 0 | readed frmae type | 0 = Fixed Data, 1 = Variable Data |

| Start address + 1 | Medium | refer to <Table 2> |

| Start address + 2 Start address + 3 … |

unit readed value … |

unit of M-BUS ( according to frame type ) number value, *) 6Ch, 6Dh unit : day,month,year, ... data |

| <Table 1> Data saving address and contents for class 2 data | ||

Fixed Data of M-BUS protocol always have 2( Counter 1, Counter 2) data.

Note) 6Ch unit ( 108 = date ) : day, month, year 3 data save at Memory.

6Dh ( 109 = time/date ) : minute, hour, day, month, year data save at Memory.

Note) Please refer to chapter 4 or manual of M-BUS protocol for Fixed Data, Variable Data.

| value ( hex-decimal unit) | Fixed Data |

Variable Data |

| 00h | Other |

Other |

| 01h | Oil |

Oil |

| 02h | Electricity |

Electricity |

| 03h | Gas |

Gas |

| 04h | Heat |

Heat(Volume measured at return temperature : outlet) |

| 05h | Steam |

Steam |

| 06h | Hot Water |

Hot Water |

| 07h | Water |

Water |

| 08h | H.C.A |

Heat Cost Allocator. |

| 09h | Reserved |

Compressor Air |

| 0Ah | Gas Mode 2 |

Cooling Load Meter(Volume measured at return temperature : outlet) |

| 0Bh | Heat Mode 2 |

Cooling Load Meter(Volume measured at flow temperature : inlet) |

| 0Ch | Hot Water Mode 2 |

Heat(Volume measured at flow temperature : inlet) |

| 0Dh | Water Mode 2 |

Heat/Cooling Load Meter |

| 0Eh | H.C.A Mode 2 |

Bus/System |

| 0Fh | Reserved |

Unknown Medium |

| 10h ~ 15h | - |

Reserved |

| 16h | - |

Cold Water |

| 17h | - |

Dual Water |

| 18h | - |

Pressure |

| 19h | - |

A/D Converter |

| 20h ~ FFh | - |

Reserved |

| <Table 2> Fixed/Variable Data according to Medium | ||

<Table 3>, <Table 4> are data saving address and contents for PadPlus M4 and AnDi 4 equipment(one port).

| Data saving address | Contents | Readed value | Address when Writing settings |

| Start address + 0 | frame type | 1 = Variable Data | - |

| Start address + 1 | Medium | Medium, refer to <Table 2> | |

| Start address + 2 | unit | 0 | |

| Start address + 3 | measurement value | current value | |

| Start address + 4 | unit | 6Dh = time/date | 1 |

| Start address + 5 ~ 9 | current time/date | minute, hour, day, month, year | |

| Start address + 10 | unit | 6Ch = date | 2 |

| Start address + 11 ~ 13 | Due Data value | day, month, year | |

| Start address + 14 | unit | 3 | |

| Start address + 15 | Due Date Count | day, month, year | |

| Start address + 16 | unit | 6Ch = date | 4 |

| Start address + 17 ~ 19 | Next Due Data value | day, month, year | |

| Start address + 20 ~ 23 | Special data | setting value ( Tariff A/B, Long Pulse Sampling, Multiplicator, etc ) | - |

| <Table 3> Data saving address and contents for PadPlus M4 equipment(one port) | |||

| Data saving address | Contents | Readed value | Address when Writing settings |

Start address + 0 |

frame type |

1 = Variable Data |

- |

Start address + 1 |

Medium |

Medium, refer to <Table 2> |

|

Start address + 2 |

unit |

|

0 |

Start address + 3 |

minimum value of Operation Mode |

minimum value |

|

Start address + 4 |

unit |

|

1 |

Start address + 5 |

maximum value of Operation Mode |

maximum value |

|

Start address + 6 |

unit |

|

2 |

Start address + 7 |

measurement value |

current value |

|

Start address + 8 |

Special data |

setting value |

- |

| <Table 4> Data saving address and contents for AnDi 4 equipment(one port) | |||

M-BUS for Relay Etc communication driver store the same data in WORD, DWORD, FLOAT memory, but the data format are different.

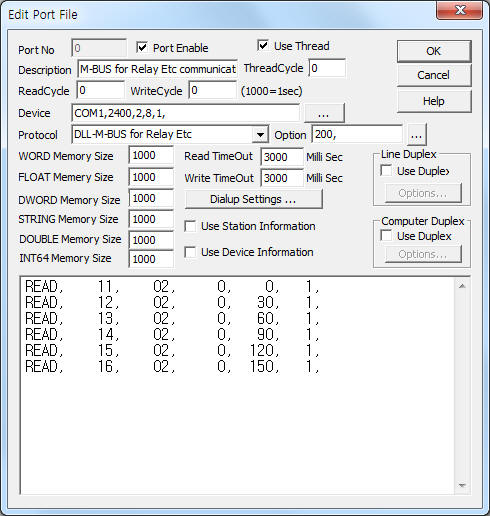

If you click the icon

![]() in protocol option part, you can see the dialog

box such as <Figure 2>. you can also set read schedule by using this part.

in protocol option part, you can see the dialog

box such as <Figure 2>. you can also set read schedule by using this part.

|

| <Figure 2> Example of M-BUS for Relay Etc communication driver’s Option dialog box |

You can set read schedule by using

![]() ,

,

![]() ,

,

![]() button and listbox of <Figure 2>.

button and listbox of <Figure 2>.

Also, you can set set Write after waiting time by using the part of 'Write After Waiting Time' shown in <Figure 2>.

|

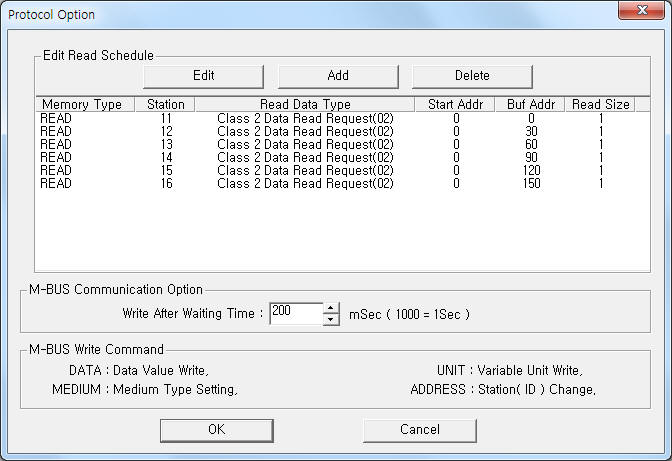

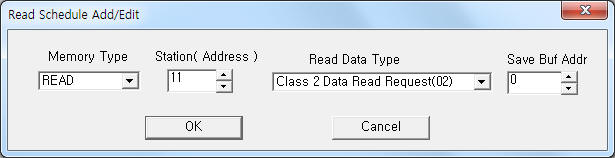

| <Figure 3> Example of M-BUS for Relay Etc communication driver’s read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialogue box of <Figure 2>, dialogue box of <Figure 3> will be shown.

You can control relay or etc by using 'writing settings'.

Digital Write

Digital write and analog write have the same setting parameters except output value.

Analog Write

Analog write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION 0 ~ 254 station address.

3) ADDRESS writing address when UNIT, DATA command.

4) Extra1 Write command.

DATA : data writing command,

UNIT : unit writing command,

MEDIUM : change Medium command,

ADDRESS : change Address command.

5) Extra2 don't care.

Note) Address when DATA, UNIT write command is order number for Class 2 data.

So, address of Fixed Data(readed data) = 0 ~ 1, Variable Data = 0 ~ count of readed data - 1..

Write example 1)

PORT:0, station:12, ADDRESS:0000, Extra1: DATA, Extra2 : 0

The setting parameter shown above is setting example for 0(1st) data value.

Connection of main power and communication cable are as follows.

Connection of main power

Please connect 24V DC main power to power connector such as <Figure 4>.

|

| <Figure 4> Connection example of main power and communication cable to Relay controller |

Connection of communication cable

Please connect RS-485 communication cable each equipment's M-BUS +, - connector.

Also, connect cross RS-232C(normally) communication cable to PW3 RS-485 to RS-232C controller such as <Figure 4>.

Note) PadPlus M4, AnDi 4, ... have 4 port. So, 1 Port = 1 Station. ( PadPlus M4 have 4 Station Address )

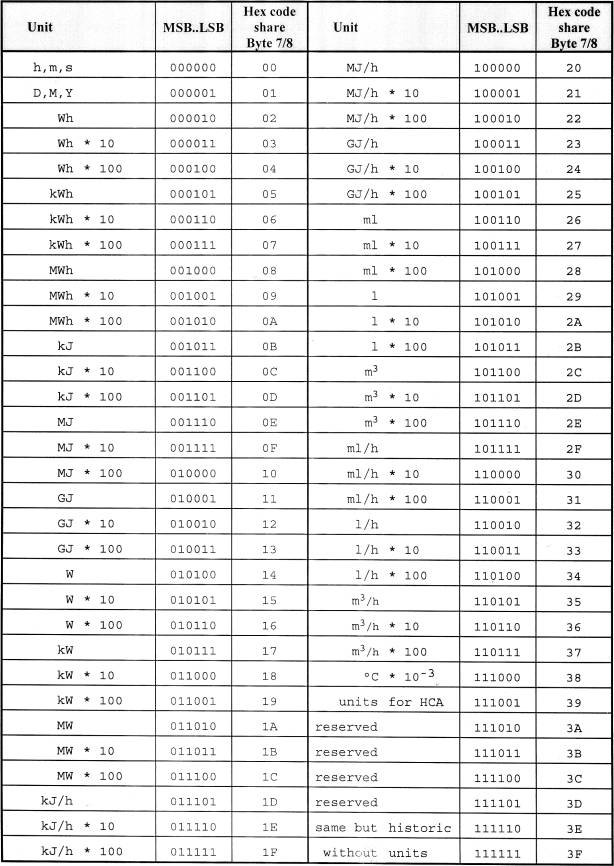

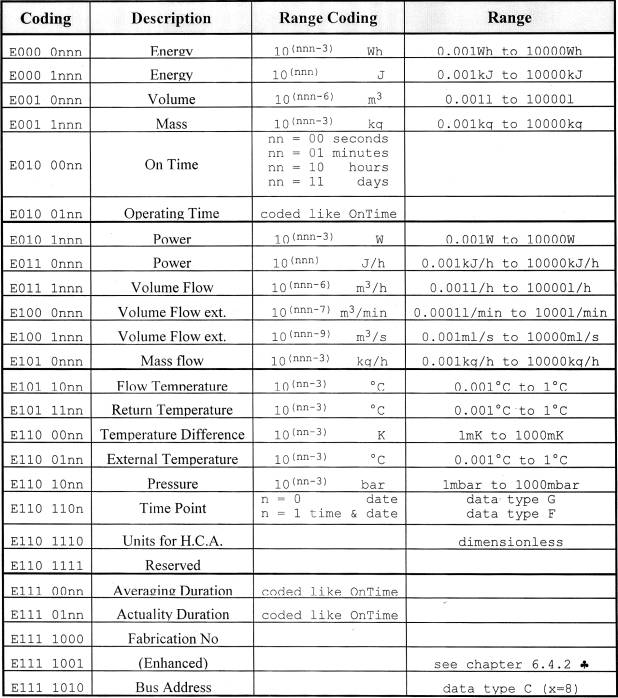

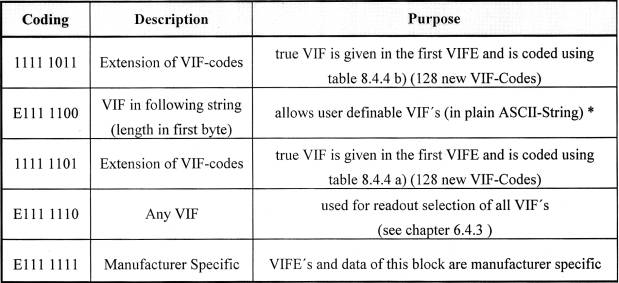

<Table 5>, <Table 6> are Unit and contents of Fixed, Varialbe data frame.

|

| <Figure 5> Unit and contents of Fixed data frame(hex-decimal) |

|

<Figure 6> Unit and contents of Variable data frame(binary, Ebit = don't care) |