MYPRO CPIII( and MDC ) communication driver is the driver to communicate with screw compressor of MAYEKAWA Total System21 in Japan.

Note) Station number of MYPRO CPIII/MDC controller can use 1 ~ 31. ( don't use 0 station number )

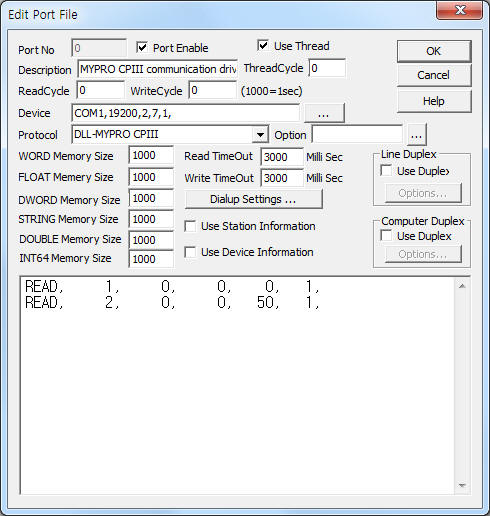

<Figure 1> is read setting example of MYPRO CPIII communication driver.

|

| <Figure 1> Read setting example of MYPRO CPIII communication driver |

Device part of <Figure 1> input Com Port(COM1), Baud Rate(19200), Parity Bit(2), Data Bit(7), Stop Bit(1) respectively, according to setting of controller.

Note) Baud rate, parity bit, data bit, stop bit of MYPRO CPIII/MDC can set by using front panel's setting button.

MYPRO CPIII communication driver read schedule

Read schedule setting parameters are as follows:

1) Station – 1 ~ 31 station number. ( don't use 0 station number )

2) Read command – don't care.

3) Read start address – don't care.

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read size – fixed to 1. ( refer to <Table 1 > )

Read schedule example)

READ, 1, 0, 0, 0, 1,

READ, 2, 0, 0, 50, 1,

<Table 1> is data saving address and contents of MYPRO CPIII communication driver.

<Table 2> is data value and meanings for operation mode. <Table 3> is contacts and contents for each bit.

<Table 4> is name and alarm contents for each bit.

Data saving address |

Contnets |

Remarks |

Start addr + 0 ~ 15 |

current value of analog input 1 ~ 16 |

|

Start addr + 16 ~ 23 |

calculation value 1 ~ 8 |

|

Start addr + 24 ~ 29 |

setting value 1 ~ 6 |

|

Start addr + 30 |

operation mode |

refer to <Table 2> |

Start addr + 31 ~ 32 |

status of 32 bit input, output contact |

refer to <Table 3> |

Start addr + 33 ~ 34 |

alarm status 32 bit |

refer to <Table 4> |

| <Table 1> Data saving address and contents of MYPRO CPIII communication driver | ||

Operation mode |

Serial communication mode ( hex-decimal ) |

|

Off |

On |

|

manual |

10 |

15 |

automatic |

20 |

25 |

remote |

30 |

35 |

remote.automatic |

40 |

45 |

| <Table 2> Data value and meanings for operation mode | ||

Bit positon |

Contacts |

Contents |

b0 |

D/O-01 |

freezer (1/ 2) |

b1 ~ b3 |

D/O-02 ~ D/O-04 |

capacity control solenoid valve 1/3 ~ 3/3 for freezer (1/ 2) |

b4 |

D/O-05 |

irrigation solenoid valve |

b5 |

D/O-06 |

YOSAKU expansion valve (1/3) |

b6 |

D/O-07 |

auxiliary machinery |

b7 |

D/O-08 |

middle irrigation solenoid valve of freezer (1/2) |

b8 |

D/O-09 |

batch alarm |

b9 |

D/I-01 |

emergency stop |

b10 |

D/I-02 |

cooling water pressure rising switch |

b11 |

D/I-03 |

brine/cold water pressure rising switch |

b12 |

D/I-04 |

motor winding temperature rising switch of freezer (1/2) |

b13 |

D/I-05 |

operation(run) confirm of freezer (1/2) |

b14 |

D/I-06 |

external operation command |

b15 |

D/I-07 |

iInterlock |

b16 |

D/O-10 |

freezer 2/2 |

b17 ~ b19 |

D/O-11 ~ D/O-13 |

capacity control solenoid valve 1/3 ~ 3/3 for freezer 2/ 2 |

b20 |

D/O-14 |

YOSAKU expansion valve (2/3) |

b21 |

D/O-15 |

YOSAKU expansion valve (3/3) |

b22 |

D/O-16 |

don't use |

b23 |

D/O-17 |

middle irrigation solenoid valve of freezer (2/2) |

b24 ~ b27 |

DI/O |

don't use |

b28 |

D/I-08 |

motor winding temperature rising switch of freezer 2/2 |

b29 |

D/I-09 |

operation(run) confirm of freezer 2/2 |

b30 |

D/I-10 |

operation command of external freezer for 1 unit |

b31 |

D/I-11 |

external setting switching command |

| <Table 3> Contacts and contents for each bit | ||

Bit positon |

Name |

Contents |

b0 |

C1HDP |

discharge pressure rising switch shutdown alarm of freezer (1/2) |

b1 |

C1LOP |

irrigation, differential pressure lowering shutdown alarm of freezer (1/2) |

b2 |

C1HDT |

discharge temperature rising switch shutdown alarm of freezer (1/2) |

b3 |

C1HMA |

motor over-current shutdown alarm of freezer (1/2) |

b4 |

C1 SF |

operation shutdown alarm of freezer (1/2) |

b5 |

C1HMT |

motor winding temperature rising shutdown alarm of freezer (1/2) |

b6 |

C1HIP |

middle pressure rising shutdown alarm of freezer (1/2) |

b7 |

C1HOT |

irrigation temperature rising shutdown alarm of freezer (1/2) |

b8 |

C2HDP |

discharge pressure rising switch shutdown alarm of freezer 2/2 |

b9 |

C2LOP |

irrigation, differential pressure lowering shutdown alarm of freezer 2/2 |

b10 |

C2HDT |

discharge temperature rising switch shutdown alarm of freezer 2/2 |

b11 |

C2HMA |

motor over-current shutdown alarm of freezer 2/2 |

b12 |

C2 SF |

operation shutdown alarm of freezer 2/ 2 |

b13 |

C2HMT |

motor winding temperature rising shutdown alarm of freezer 2/2 |

b14 |

C2HIP |

middle pressure rising shutdown alarm of freezer 2/2 |

b15 |

C2HOT |

irrigation temperature rising shutdown alarm of freezer 2/2 |

b16 |

L CWP |

cooling water pressure lowering shutdown alarm |

b17 |

L BCP |

brine/cold water pressure lowering shutdown alarm |

b18 |

L COT |

brine/cold water temperature lowering shutdown alarm |

b19 |

LSUCP |

inhalation pressure lowering shutdown alarm |

b20 |

EMR |

emergency stop shutdown alarm |

b21 |

INTLK |

iInterlock shutdown alarm |

b22 ~ b23 |

|

don't use, |

b24 |

H COT |

brine/cold water temperature rising pre-alarm |

b25 |

L SSH |

inhalation overheated steam lowering pre-alarm |

b26 |

LISH |

middle overheated steam pre-alarm |

b27 ~ b31 |

|

don't use |

| <Table 4> Name and alarm contents for each bit | ||

MYPRO CPIII communication driver store the same data in WORD, DWORD, FLOAT, STRING memory, but the data format are different.

If you click the icon ![]() in protocol option part at

<Figure 1>, you

can see the dialog box such as <Figure 2>. you can also set read schedule by

using this part.

in protocol option part at

<Figure 1>, you

can see the dialog box such as <Figure 2>. you can also set read schedule by

using this part.

|

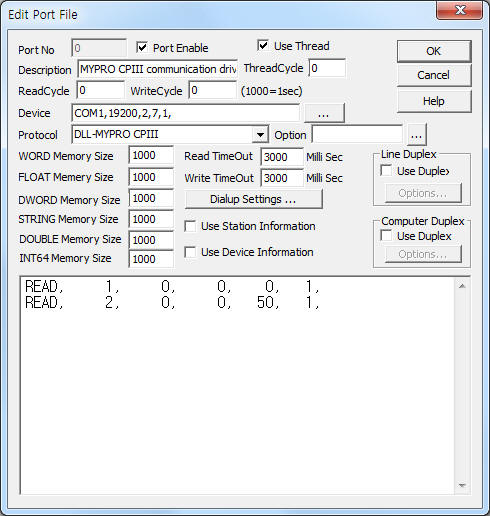

| <Figure 2> Example of MYPRO CPIII communication driverí»s Option dialog box |

You can set read schedule by using ![]() ,

, ![]() ,

, ![]() button and listbox of <Figure

2>.

button and listbox of <Figure

2>.

|

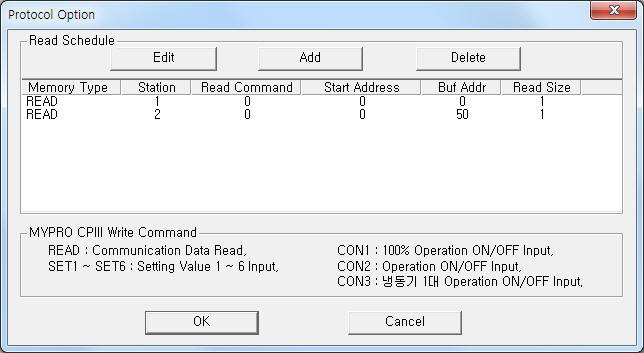

| <Figure 3> Example of MYPRO CPIII communication driverí»s read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialogue box of <Figure 2>, dialogue box of <Figure 3> is shown.

You can set MYPRO CPIII/MDC controller by using 'write settings'.

Digital Write

Digital write and analog write have the same setting parameters except output value.

Analog Write

Analog write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION 1 ~ 31 station number. ( don't use 0 station number )

3) ADDRESS data saving start address when READ write command. ( refer to <Table 1> )

4) Extra1 writing command = READ, SET1 ~ SET6, CON1 ~ CON3. ( refer to <Table 5> )

5) Extra2 don't care.

<Table 5> is write command and contents of MYPRO CPIII communication driver.

Write command |

Contents |

READ |

read command ( refer to <Table 1> ) |

SET1 ~ SET6 |

setting command for setting value 1 ~ 6 |

CON1 |

operation command of 100 % |

CON2 |

operation command |

CON3 |

run command for freezer 1 unit |

| <Table 5> Write command and contents of MYPRO CPIII communication driver | |

Write example 1)

PORT:0, station:1, ADDRESS:0100, Extra1: READ, Extra2 : 0

The setting parameter shown above is read request setting example of station 1 MYPRO CPIII controller.

After reading, the readed data save at 100 ~ 134 address WORD, DWORD, FLOAT memory such as <Table 1>.

Write example 2)

PORT:0, station:1, ADDRESS:0000, Extra1: SET1, Extra2 : 0

The setting parameter shown above is setting example for setting value 1.

Write example 3)

PORT:0, station:2, ADDRESS:0000, Extra1: SET6, Extra2 : 0

The setting parameter shown above is setting example for setting value 6.

Write example 4)

PORT:0, station:1, ADDRESS:0000, Extra1: CON1, Extra2 : 0

The setting parameter shown above is 100% operation command control( On or Off ) example of station 1 MYPRO CPIII controller.

Write example 5)

PORT:0, station:2, ADDRESS:0000, Extra1: CON1, Extra2 : 0

The setting parameter shown above is 100% operation command control( On or Off ) example of station 2 MYPRO CPIII controller.

Write example 6)

PORT:0, station:1, ADDRESS:0000, Extra1: CON3, Extra2 : 0

The setting parameter shown above is run command for freezer 1 unit control( On or Off ) example of station 1 MYPRO CPIII controller.

Please connect RS-485 communication cable to A( + ), B( - ) connector of MYPRO CPIII/MDC controller such as <Figure 4>.

RS-485 of computer MYPRO-CPIII/MDC controller

Tx+, Rx+ -------------------------------------- A connector

Tx-, Rx- -------------------------------------- B connector

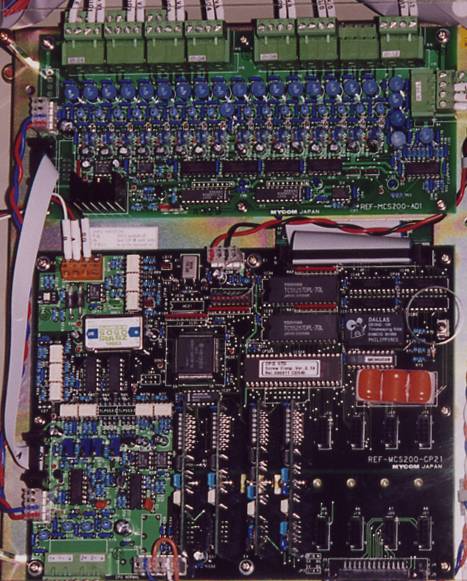

<Figure 4> is appearance of MYPRO CPIII/MDC controller.

|

| <Figure 4> Appearance of MYPRO CPIII/MDC controller |