MODBUS2 communication driver for ION 8000 Series controller is the driver to communicate with power meter ION 7500, 7600, 8000 Series of POWER MEASUREMENT in Canada.

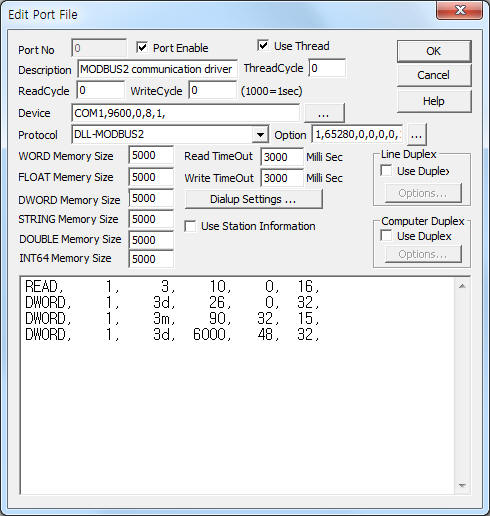

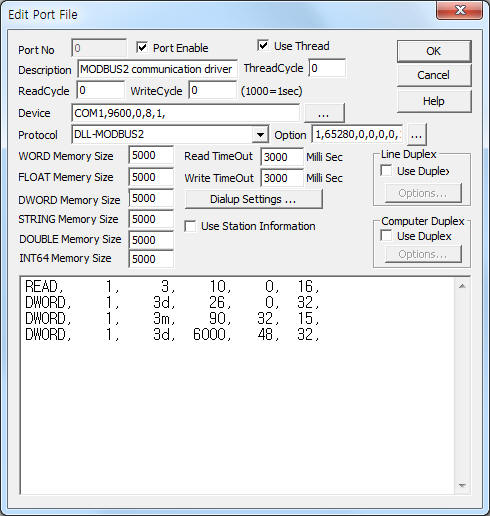

<Figure 1> is read setting example of MODBUS2 communication driver for ION 8000 Series.

|

| <Figure 1> Read setting example of MODBUS2 communication driver for ION 8000 Series |

Device part of <Figure 1> input Com Port(COM1), Baud Rate(9600), Parity Bit(0), Data Bit(8), Stop Bit(1) respectively, according to the controller.

In protocol option part, you can set the following: whether to check CRC(1 = check, 0 = No check), bit write value that corresponds to ON(Default = 65280), protocol type(1 = IP protocol, 0 = Serial protocol), bit write value that corresponds to OFF(Default = 0), whether to use WORD size(1 = Not using WORD size, 0 = using WORD size, Default = 0), whether to use multi write(0 = Not using multi write, 1 = using multi write, Default = 0), state value storage position for comparison of data(input WORD memory address, Defualt = 1000). Each argument is a comma-delimited.

Note) Baud rate, parity bit, data bit, stop bit can set by using front panet switch or write setting.

COM1, COM2 of ION series controller use RS-232C, RS-485 communication port.

ION series controller use DLL-MODBUS2 communication driver. So you havet to set 'MODBUS RTU' protocol at setting of power meter.

MODBUS2 communication driver for ION 8000 Series controller read schedule

Read schedule setting parameters are as follows:

1) Station – 1 ~ 247 modbus station number of controller.

2) Read Command – Read command.

3 – Reading the data of WORD unit.

3D – Reading the data of DWORD unit ( WORD order : LO, HI ).

3d – Reading the data of DWORD unit ( WORD order : HI, LO ).

3lD, 3LD – Reading the data of 8 BYTE unit ( WORD order : LO, HI ).

3ld, 3Ld – Reading the data of 8 BYTE unit ( WORD order : HI, LO ).

3M – Reading the special data[HI WORD x 10000 + LO WORD] of DWORD unit ( WORD order : LO, HI ).

3m – Reading the special data[HI WORD x 10000 + LO WORD] of DWORD unit ( WORD order : HI, LO ).

3lM, 3LM – Reading the special data[HI WORD x 10000 + LO WORD] of 8 BYTE unit ( WORD order : LO, HI ).

3lm, 3Lm – Reading the special data[HI WORD x 10000 + LO WORD] of 8 BYTE unit ( WORD order : HI, LO ).

3s – Reading the special data[16 BYTE BCD ASCII].

3F – Reading the data of FLOAT unit ( WORD order : LO, HI ).

3F2 – Reading the data of FLOAT unit ( WORD order : LO, HI ).

3f – Reading the data of FLOAT unit ( WORD order : HI, LO ).

3f2 – Reading the data of FLOAT unit ( WORD order : HI, LO ).

1X, 2X – Reading the data of BIT unit ( 1xxxx, 2xxxx Modbus address ).

1XB, 2XB – Reading the data of BIT unit ( 1xxxx, 2xxxx Modbus address ).

3B – Reading the data of BYTE unit.

3) Read Start Address – Read start address. ( Modbus address - 1 )

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read Size – Read size of data.

3 – WORD unit,

3D, 3d, 3M, 3m, 3F, 3F2, 3f, 3f2 – 2 WORD unit,

3LD, 3ld, 3LM, 3lm – 4 WORD unit.

3s – 8 WORD unit,

1X, 2X – WORD unit,

1XB, 2XB – BIT unit ( 1 ~ 15 = 1 WORD, 16 ~ 31 = 2 WORD, ¡¦).

3B – BYTE unit.

Read schedule example)

READ, 1, 3, 10, 0, 16,

DWORD, 1, 3d, 26, 0, 32,

DWORD, 1, 3m, 90, 32, 15,

DWORD, 1, 3d, 6000, 48, 32,

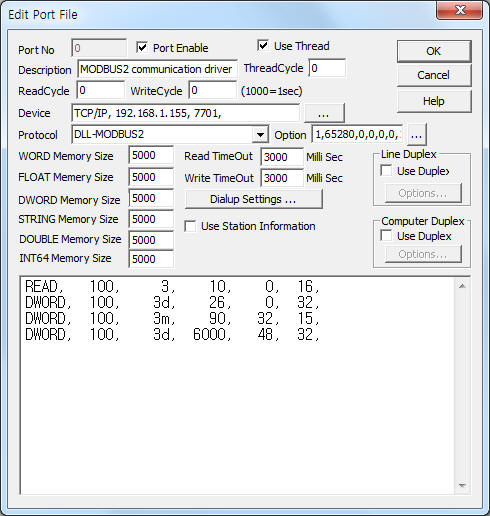

Setting of when you set TCP/IP device

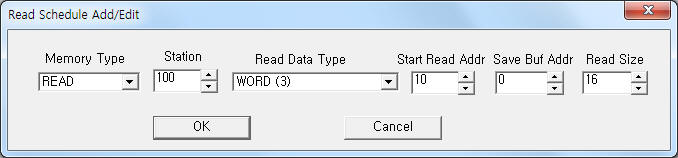

<Figure 2> is read setting example of MODBUS2 communication driver for ION 8000 Series when using the TCP/IP device.

|

| <Figure 2> Read setting example of MODBUS2 communication driver for ION 8000 Series when using the TCP/IP device |

Device part of <Figure 2> input Device type(TCP/IP), IP address of PLC(192.168.1.155), service port of TCP/IP protocol ( fixed to 7701 when Modbus RTE mode ),respectively.

In protocol option part, you can set the following: whether to check CRC(1 = check, 0 = No check), bit write value that corresponds to ON(Default = 65280), protocol type(1 = IP protocol, 0 = Serial protocol), bit write value that corresponds to OFF(Default = 0), whether to use WORD size(1 = Not using WORD size, 0 = using WORD size, Default = 0), whether to use multi write(0 = Not using multi write, 1 = using multi write, Default = 0), state value storage position for comparison of data(input WORD memory address, Defualt = 1000). Each argument is a comma-delimited.

Note) IP address can set by using front panet switch(COM3 part).

When you using TCP/IP device, the station is fixed to 100. Also serive port is fixed to 7701 when Modubos RTU mode. ( Mosbus TCP = 502, ION = 7700 )

MODBUS2 communication driver for ION 8000 Series controller read schedule

Read schedule setting parameters are as follows:

1) Station – fixed to 100 when TCP/IP device.

2) Read Command – Read command.

3 – Reading the data of WORD unit.

3D – Reading the data of DWORD unit ( WORD order : LO, HI ).

3d – Reading the data of DWORD unit ( WORD order : HI, LO ).

3lD, 3LD – Reading the data of 8 BYTE unit ( WORD order : LO, HI ).

3ld, 3Ld – Reading the data of 8 BYTE unit ( WORD order : HI, LO ).

3M – Reading the special data[HI WORD x 10000 + LO WORD] of DWORD unit ( WORD order : LO, HI ).

3m – Reading the special data[HI WORD x 10000 + LO WORD] of DWORD unit ( WORD order : HI, LO ).

3lM, 3LM – Reading the special data[HI WORD x 10000 + LO WORD] of 8 BYTE unit ( WORD order : LO, HI ).

3lm, 3Lm – Reading the special data[HI WORD x 10000 + LO WORD] of 8 BYTE unit ( WORD order : HI, LO ).

3s – Reading the special data[16 BYTE BCD ASCII].

3F – Reading the data of FLOAT unit ( WORD order : LO, HI ).

3F2 – Reading the data of FLOAT unit ( WORD order : LO, HI ).

3f – Reading the data of FLOAT unit ( WORD order : HI, LO ).

3f2 – Reading the data of FLOAT unit ( WORD order : HI, LO ).

1X, 2X – Reading the data of BIT unit ( 1xxxx, 2xxxx Modbus address ).

1XB, 2XB – Reading the data of BIT unit ( 1xxxx, 2xxxx Modbus address ).

3B – Reading the data of BYTE unit.

3) Read Start Address – Read start address. ( Modbus address - 1 )

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read Size – Read size of data.

3 – WORD unit,

3D, 3d, 3M, 3m, 3F, 3F2, 3f, 3f2 – 2 WORD unit,

3LD, 3ld, 3LM, 3lm – 4 WORD unit.

3s – 8 WORD unit,

1X, 2X – WORD unit,

1XB, 2XB – BIT unit ( 1 ~ 15 = 1 WORD, 16 ~ 31 = 2 WORD, ¡¦).

3B – BYTE unit.

Read schedule example)

READ, 100, 3, 10, 0, 16,

DWORD, 100, 3d, 26, 0, 32,

DWORD, 100, 3m, 90, 32, 15,

DWORD, 100, 3d, 6000, 48, 32,

<Table 1> is read address and contents of word area.

| Read address (Modbus address-1) | Contents |

| 10 | Vln a |

| 11 | Vln b |

| 12 | Vln c |

| 13 | Vln avg |

| 14 | Vll ab |

| 15 | Vll bc |

| 16 | Vll ca |

| 17 | Vll avg |

| 18 | Ia |

| 19 | Ib |

| 20 | Ic |

| 21 | I avg |

| 22 | I unbal |

| 23 | V unbal |

| 24 | Freq |

| 25 | I4 |

| <Table 1> Read address and contents of word area | |

Range of word data are as follows.

. Normal input : 0 ~ 6553. modbus data expression value : 0 ~ 65530. So, you have to read value x 10 : SCADA Server ratio= (max-min) x 10.

. Voltage data (154,000 V, 22,900 V, ..) can't display normal input range. You can solve this problem as follows :

1) Change the value of 7150 address data( word area maximum value of normal input data ) to 65535, 655350 or 6553500 by using 'analog write'. ( Extra1 of analog tag : 16d )

2) Change the value of 7166 address data( word area maximum value of normal output data ) to 65535 by using 'analog write'. ( Extra1 of analog tag : 16d )

<Table 2>, <Table 3> are read address and contents of normal dword, M10K dword area.

Read address (Modbus address-1) |

Contents |

Remarks |

26 ~ 27 |

KW a |

DWORD HI/LO data ( 3d ) |

28 ~ 29 |

KW b |

|

30 ~ 31 |

KW c |

|

32 ~ 33 |

KW tot |

|

34 ~ 35 |

KVAR a |

|

36 ~ 37 |

KVAR b |

|

38 ~ 39 |

KVAR c |

|

40 ~ 41 |

KVAR tot |

|

42 ~ 43 |

KVA a |

|

44 ~ 45 |

KVA b |

|

46 ~ 47 |

KVA c |

|

48 ~ 49 |

KVA tot |

|

50 ~ 51 |

pf sign a |

|

52 ~ 53 |

pf sign b |

|

54 ~ 55 |

pf sign c |

|

56 ~ 57 |

pf sign tot |

|

58 ~ 59 |

Vll Avg max |

|

60 ~ 61 |

I Avg max |

|

62 ~ 63 |

Kw Total max |

|

64 ~ 65 |

KVAR Total max |

|

66 ~ 67 |

KVA Total max |

|

68 ~ 69 |

Freq max |

|

70 ~ 71 |

Vll Avg min |

|

72 ~ 73 |

I Avg min |

|

74 ~ 75 |

Freq min |

|

76 ~ 77 |

KW sd del-rec |

|

78 ~ 79 |

KVA sd del+rec |

|

80 ~ 81 |

KVAR sd del-rec |

|

82 ~ 83 |

KW sd max del-rec |

|

84 ~ 85 |

KVA sd max del+rec |

|

86 ~ 87 |

KVAR sd max del-rec |

|

88 ~ 89 |

Phase Rev(ersal) |

|

| <Table 2> Read address and contents of normal dword area | ||

Read address (Modbus address-1) |

Contents |

Remarks |

90 ~ 91 |

KWh del |

DWORD MOD LO/HI data (HI WORD x 10000 + LO WORD)

( 3m ) |

92 ~ 93 |

KWh rec |

|

94 ~ 95 |

KWh del+rec |

|

96 ~ 97 |

KWh del-rec |

|

98 ~ 99 |

KVARh del |

|

100 ~ 101 |

KVARh rec |

|

102 ~ 103 |

KVARh del+rec |

|

104 ~ 105 |

KVARh del-rec |

|

106 ~ 107 |

KVAh del+rec |

|

108 ~ 109 |

V1 THD mx |

|

110 ~ 111 |

V2 THD mx |

|

112 ~ 113 |

V3 THD mx |

|

114 ~ 115 |

I1 THD mx |

|

116 ~ 117 |

I2 THD mx |

|

118 ~ 119 |

I3 THD mx |

|

| <Table 3> Read address and contents of M10K dword area | ||

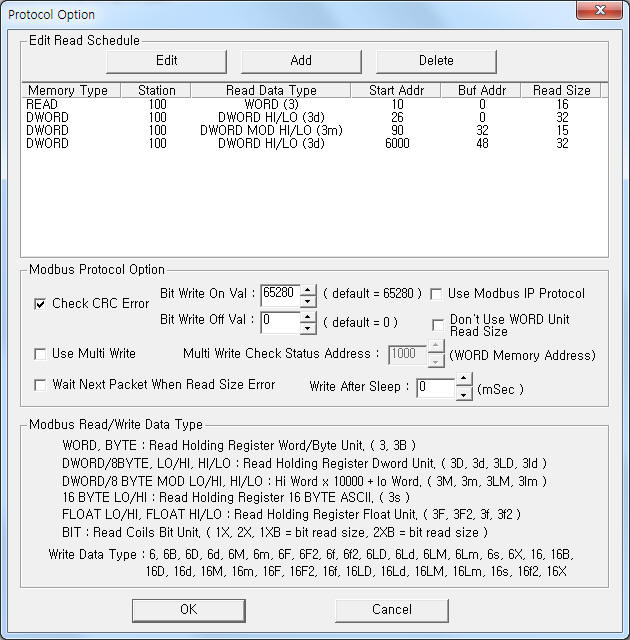

If you click the icon ![]() in protocol option part at

<Figure 1>, <Figure 2>, you

can see the dialogue box such as <Figure 3>. you can also set read schedule by

using this part.

in protocol option part at

<Figure 1>, <Figure 2>, you

can see the dialogue box such as <Figure 3>. you can also set read schedule by

using this part.

|

| <Figure 3> Example of MODBUS2 communication driver for ION 8000 Series communication driver¡¯s Option dialog box |

You can set read schedule by using ![]() ,

, ![]() ,

, ![]() button and listbox of <Figure

3>.

button and listbox of <Figure

3>.

Also, you can set whether to check CRC by using the part of 'Check CRC Error' of <Figire 3>.

|

| <Figure 4> Example of MODBUS2 communication driver for ION 8000 Series communication driver¡¯s read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialogue box of <Figure 3>, dialogue box of <Figure 4> is shown.

You can set ION 8000 Series controller by using 'writing settings'.

Digital Write

Digital write and analog write have the same setting parameters except output value.

Analog Write

Analog write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION Modbus station number of controller.

Serial : 1 ~ 247.

TCP/IP : fixed to 100.

3) ADDRESS Decimal uint writing address(modbus address - 1).

4) Extra1 Writing data type.

16 – Writing the data of WORD unit.

16D – Writing the data of DWORD unit ( WORD order : LO, HI ).

16d – Writing the data of DWORD unit ( WORD order : HI, LO ).

16lD, 16LD – Writing the data of 8 BYTE unit ( WORD order : LO, HI ).

16ld, 16Ld – Writing the data of 8 BYTE unit ( WORD order : LO, HI ).

16M – Writing the special data[HI WORD x 10000 + LO WORD] of DWORD unit ( WORD order : LO, HI ).

16m – Writing the special data[HI WORD x 10000 + LO WORD] of DWORD unit ( WORD order : HI, LO ).

16lM, 16LM – Writing the special data[HI WORD x 10000 + LO WORD] of 8 BYTE unit ( WORD order : LO, HI ).

16lm, 16Lm – Writing the special data[HI WORD x 10000 + LO WORD] of 8 BYTE unit ( WORD order : HI, LO ).

16s – Writing the special data[16 BYTE BCD ASCII].

16F – Writing the data of FLOAT unit ( WORD order : LO, HI ).

16F2 – Writing the data of FLOAT unit ( WORD order : LO, HI ).

16f – Writing the data of FLOAT unit ( WORD order : HI, LO ).

16f2 – Writing the data of FLOAT unit ( WORD order : HI, LO ).

16B – Writing the data of BYTE unit.

16H_TIME – transmit the current time of computer to HICM equipment. (You have to write 6 word one by one - year, month, day, hour, minute, second / only word write)

5) Extra2 Don't care.

Note) You can write PT, CT, RESET, ... value only when the Password is enabled. ( refer to Password setting )

Write example 1)

PORT:0, station:1, ADDRESS:3000, Extra1: 16, Extra2 : 0

The setting parameter shown above is a setting example of 3000 (modbus address = 3001 ) address by Word data.

Write example 2)

PORT:0, station:1, ADDRESS:6000, Extra1: 16d, Extra2 : 0

The setting parameter shown above is a setting example of 6000 (modbus address = 6001 ) address by Dword data.( WORD order : HI, LO )

Write example 3)

PORT:0, station:1, ADDRESS:7150, Extra1: 16d, Extra2 : 0

The setting parameter shown above is a setting example of 7150 (modbus address = 7151 ) address by Dword data.( WORD order : HI, LO )

Connection of communication cable and main power line are as follows.

Connection of RS-232C(COM1) communication cable

Please connect normal(cross) RS-232C communication cable to COM1 9pin connector.

Connection of RS-485(COM1 or COM2) communication cable

Please connect RS-485 communication cable to +, - connector.

Computer side ION 8000 SERIES side

Tx+, Rx+ --------------------------------- +

Tx-, Rx- --------------------------------- -

Connection of ethernet communication cable

Please connect ethernet communication cable to RJ45(UTP cable) connector of ION 8000 SERIES Meter.

Connection of main power

Please connect 85 ~ 240V, 47/63 HZ AC or 110 ~ 330 V DC 20VA main power to L, N connector of ION 8000 SERIES Meter such as <Figure 5>.

|

| <Figure 5> Connection example of communication cable and main power to ION 8000 SERIES Power Meter |

Setting meter address and baud rate are as follows.

Meter address and baudrate of COM 1, COM2, COM3 setting

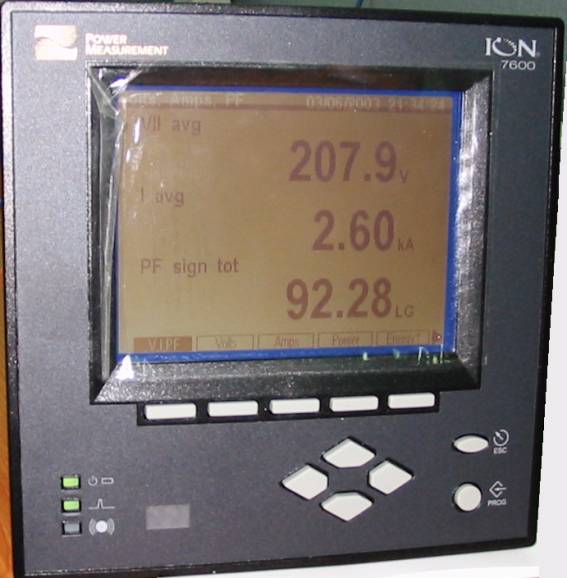

Baud rate of COM1, COM2, COM3 can set by using front panel such as follows. ( refer to <Figure 6> )

1) Press 'PROG' button.

2) Please select 'COM1 SETUP', 'COM2 SETUP' or 'COM3 SETUP' by using 'Up', 'Down' button.

3) Press 'PROG' button.

4) Then will be displayed 'PROTOCOL' and 'HARDWARE' menu for COM1, 'PROTOCOL' setting menu for COM2.

5) Please set 'Protocol type', 'Baud rate', 'Unit ID', etc at PROTOCOL setting menu.

6) Set 'Communication MODE( RS-232C, RS-485)', 'FLOW (RTS + DELAY, RTS/CTS )' at HARDWARE menu for COM1.

7) Press 'PROG' button. Then will be displayed 'Confirm' message. Press 'PROG' button again.(input Password)

|

| <Figure 6> Appearance of ION 8000 SERIES Power Meter |

Setting of IP address, Subnet Mask

IP address and Subnet mask can set by using front panel such as follows.

1) Press 'PROG' button.

2) Please select 'NETWORK SETUP' by using 'Up', 'Down' button.

3) Press 'PROG' button.

4) Please set 'IP address', 'Subnet Mask', 'Gateway', etc at NETWORK setup menu.

5) Press 'PROG' button. Then will be displayed 'Confirm' message. Press 'PROG' button again.(input Password)

Setting of password enable/disable can set by using front panel such as follows.

1) Press 'PROG' button.

2) Please select 'SECURITY SETUP' by using 'Up', 'Down' button.

3) Press 'PROG' button.

4) Please set 'ENABLED'(YES : Enable, NO : Disable) at SECURITY setup menu.

5) Press 'PROG' button. Then will be displayed 'Confirm' message. Press 'PROG' button again.(input Password)