INGERSOLL-RAND MP3/MVP communication driver is the driver to communicate with air compressor controller of Ingersoll-Land Air Compressors.

Note) INGERSOLL-RAND MP3/MVP communication driver communicate with PONI(Product Operated Network Interface) card and MINT(Master Incom Network Translator) Box of Westinghouse company.

Baud rate, Parity bit bit and etc of MINT Box can set by usnig Dip switch.

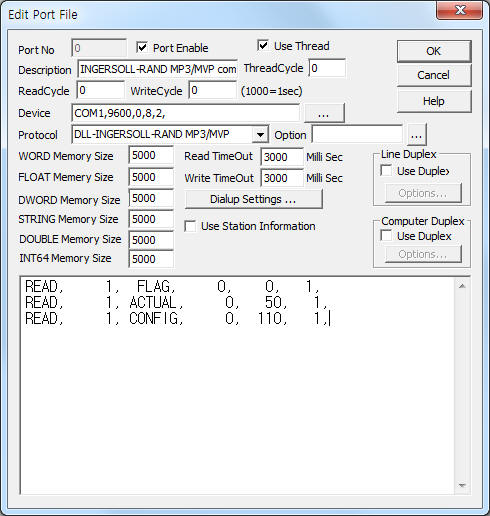

<Figure 1> is read setting example of INGERSOLL-RAND MP3/MVP communication driver.

|

| <Figure 1> Read setting example of INGERSOLL-RAND MP3/MVP communication driver |

Device part of <Figure 1> input Com Port(COM1), Baud Rate(9600), Parity Bit(0), Data Bit(8), Stop Bit(2) respectively, according to the MINT Box's setting.

Also you can set 'saving start address of readed string' (0 ~ 9999, default = 0 ), 'received string saving count'(default = 200), 'Timeout when multi line reading' by using option part.

INGERSOLL-RAND MP3/MVP communication driver read schedule

Read schedule setting parameters are as follows:

1) Station – 0 ~ 4095 network address of PONI card.

2) Read command – MP3 – STATUS, FLAG, ACTUAL, ALERT, SHUTDOWN, CONFIG, BYPASS, INLET, ( refer to <Table 1> )

MVP - M_STATUS, M_EXT, M_FLAG, M_ANA, M_SET.

3) Read Start Address – Don't care(fixed to 0).

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read Size – Fixed to according read command. ( refer to <Table 1> )

Read schedule example)

READ, 1, FLAG, 0, 0, 1,

READ, 1, ACTUAL, 0, 50, 1,

READ, 1, CONFIG, 0, 110, 1,

<Table 1> is read command and contents of MP3 Model.

| Read command | Contents | Read size | Data type | Remarks |

| STATUS | Short Status | 4 | BYTE, 4Bit, etc | refer to <Table 2> |

| FLAGS | Status Flags | 42 | BYTE | refer to <Table 3> |

| ACTUAL | Actual Values (A) | 51 | WORD | refer to <Table 4> |

| ALERT | Alert Values (B) | |||

| SHUTDOWN | Shutdown Values (C) | |||

| CONFIG | Configuration | 51 | BYTE | refer to <Table 5> |

| BYPASS | Bypass Value Status | 4 | BYTE/WORD | refer to <Table 6> |

| INLET | Inlet Value Status | |||

| <Table 1> Read command and contents of MP3 Model | ||||

<Table 2>, <Table 3>, <Table 4> are data saving address and contents for STATUS, FLAGS, ACTUAL, ALERT, SHUTDOWN read command.

<Table 5>, <Table 6> are data saving address and contents for CONFIG, BYPASS, INLET read command.

| Data Saving Address | Contents | Data type |

| Start Add + 0 | 0 ~ 5 Bit

: Reserved ( 0 ) 6 Bit : Flag, 7 Bit : Flag, |

BYTE |

| Start Add + 1 | Product ID ( always 4 ) | 6 Bit (0 ~ 64) |

| Start Add + 2 | Version | 4 Bit (0 ~ 16 ) |

| Start Add + 3 | Division Code | 6 Bit (0 ~ 64 ) |

| <Table 2> Data saving address and contents for STATUS read command | ||

| Data Saving Address | Contents | Data type | Remarks |

| Start Add + 0 ~ 10 | Status Flag 0 ~ 10 | BYTE | 5, 6, 8, 9, 10 Status = don't use |

| Start Add + 11 ~ 14 | Alert Status 0 ~ 3 | ||

| Start Add + 15 ~ 18 | Shutdown Status 0 ~ 3 | ||

| Start Add + 19 ~ 22 | Alert History 0 ~ 3 | ||

| Start Add + 23 ~ 26 | Shutdown History 0 ~ 3 | ||

| Start Add + 27 ~ 30 | Alert Enabled 0 ~ 3 | ||

| Start Add + 31 ~ 34 | Shutdown Enabled 0 ~ 3 | ||

| Start Add + 35 | Run Time | DWORD (3 Byte) | save also DWORD Start Add + 35 |

| Start Add + 36 | Starts (Lo) | BYTE | |

| Start Add + 37 | Starts (Hi) | version 4.02 or later | |

| Start Add + 38 ~ 39 | Reserved | ||

| <Table 3> Data saving address and contents for FLAGS read command | |||

| Data Saving Address | Contents | Data type | Remarks |

| Start Add + 0 | Surge | WORD 0 ~ 9999 | |

| Start Add + 1 | Low Water Flow | ||

| Start Add + 2 | Low Seal Air | ||

| Start Add + 3 | Dirty Inlet Filter | ||

| Start Add + 4 | Dirty Oil Filter | ||

| Start Add + 5 | Low Oil Level | ||

| Start Add + 6 | High Condensate Level | ||

| Start Add + 7 | High Motor Temp | ||

| Start Add + 8 ~ 9 | Vibration Stage 1 ~ 2 | X 100 | |

| Start Add + 10 | Oil Pressure | ||

| Start Add + 11 | Oil Temperature | ||

| Start Add + 12 | Low Oil Temperature | ||

| Start Add + 13 | Air Temp Stage 1 | ||

| Start Add + 14 ~ 15 | Vibration Stage 3 ~ 4 | X 100 | |

| Start Add + 16 ~ 17 | Vibration Shaft A ~ B | X 100 | |

| Start Add + 18 ~ 20 | Discharge Press Stage 1 ~ 3 | ||

| Start Add + 21 | Water Temperature | ||

| Start Add + 22 ~ 23 | Air Temp Stage 2 ~ 3 | ||

| Start Add + 24 | Discharge Air Temp | ||

| Start Add + 25 ~ 29 | Temperature AA, BB, CC, DD, EE | ||

| Start Add + 30 | System Press Setpoint | ||

| Start Add + 31 ~ 32 | Current Limit High, Low | X 10 | |

| Start Add + 33 | Proportional Band | ||

| Start Add + 34 | Integral Time | ||

| Start Add + 35 | Setpoint Ramp Rate | ||

| Start Add + 36 | Reload Percent | ||

| Start Add + 37 | P1 | ||

| Start Add + 38 | Y-D Time | ||

| Start Add + 39 | Prom Version | ||

| Start Add + 40 | Prelube Time | ||

| Start Add + 41 ~ 42 | CT Ratio, Output | ||

| Start Add + 43 | YD-AAL Starter | 1 : YD-Wye delta starter 0 : AAL-Automatic Across-the-line Starter |

|

| Start Add + 44 | Pressure Transducer | 200 or 500 | |

| Start Add + 45 | Language | 0 : English, 1 : French, 2 : German 3 : Italian, 4 : Spanish |

|

| Start Add + 46 | Units | 1 : English2 : Metlic | |

| Start Add + 47 | Unload Point | BYTE data | |

| Start Add + 48 | System Pressure | ||

| Start Add + 49 | Motor Current | X 100 | |

| Start Add + 50 | Unload Delay | ||

| <Table 4> Data saving address and contents for ACTUAL, ALERT, SHUTDOWN read command | |||

Data Saving Address |

Contents |

Start Add + 0 |

Surge |

Start Add + 1 |

Low Water Flow |

Start Add + 2 |

Low Seal Air |

Start Add + 3 |

Dirty Inlet Filter |

Start Add + 4 |

Dirty Oil Filter |

Start Add + 5 |

Low Oil Level |

Start Add + 6 |

High Condensate Level |

Start Add + 7 |

High Motor Temp |

Start Add + 8 ~ 9 |

Vibration Stage 1 ~ 2 |

Start Add + 10 |

Oil Pressure |

Start Add + 11 |

Oil Temperature |

Start Add + 12 |

Low Oil Temperature |

Start Add + 13 |

Air Temp Stage 1 |

Start Add + 14 ~ 15 |

Vibration Stage 3 ~ 4 |

Start Add + 16 ~ 17 |

Vibration Shaft A ~ B |

Start Add + 18 ~ 20 |

Discharge Press Stage 1 ~ 3 |

Start Add + 21 |

Water Temperature |

Start Add + 22 ~ 23 |

Air Temp Stage 2 ~ 3 |

Start Add + 24 |

Discharge Air Temp |

Start Add + 25 ~ 29 |

Temperature AA, BB, CC, DD, EE |

Start Add + 30 |

System Press Setpoint |

Start Add + 31 ~ 32 |

Current Limit High, Low |

Start Add + 33 |

Proportional Band |

Start Add + 34 |

Integral Time |

Start Add + 35 |

Setpoint Ramp Rate |

Start Add + 36 |

Reload Percent |

Start Add + 37 |

P1 |

Start Add + 38 |

Y-D Time |

Start Add + 39 |

Prom Version |

Start Add + 40 |

Prelube Time |

Start Add + 41 ~ 42 |

CT Ratio, Output |

Start Add + 43 |

YD-AAL Starter |

Start Add + 44 |

Pressure Transducer |

Start Add + 45 |

Language |

Start Add + 46 |

Units |

Start Add + 47 |

Reserved |

Start Add + 48 |

System Pressure |

Start Add + 49 |

Motor Current |

Start Add + 50 |

Reserved |

| <Table 5> Data saving address and contents for CONFIG read command | |

| Data Saving Address | Contents | Data type |

| Start Add + 0 | Bypass, Inlet Position | BYTE |

| Start Add + 1 | System Pressure | WORD |

| Start Add + 2 | System Press Setpoint | |

| Start Add + 3 | Compressor Status | BYTE |

| <Table 6> Data saving address and contents for BYPASS, INLET read command | ||

<Table 7> is read command and contents of MVP Model.

<Table 8>, <Table 9>, <Table 10> are data saving address and contents for M_FLAG, M_ANA, M_SET read command.

| Read command | Contents | Read size | Data type | Remarks |

| M_STATUS | Short Status | 4 | BYTE, 4Bit, etc | refer to <Table 2> |

| M_EXT | Extended Status | |||

| M_FLAG | Compressor Status Flags | 7 | BYTE, etc | refer to <Table 8> |

| M_ANA | Analog Buffer | 14 | BYTE, WORD, etc | refer to <Table 9> |

| M_SET | Setpoint Buffer | 20 | refer to <Table 10> | |

| <Table 7> Read command and contents of MVP Model | ||||

| Data Saving Address | Contents | Data type | Remarks |

| Start Add + 0 | 0 ~ 5 Bit

: Reserved ( 0 ) 6 Bit : Flag, 7 Bit : Flag, |

BYTE data | Short

Status ( equal with <Table 2 > ) |

| Start Add + 1 | Product ID ( always 4 ) | 6 Bit data (0 ~ 64) | |

| Start Add + 2 | Version | 4 Bit data (0 ~ 16 ) | |

| Start Add + 3 | Division Code | 6 Bit data (0 ~ 64 ) | |

| Start Add + 4 | Shutdown Flags | BYTE data | |

| Start Add + 5 | Alert Flags | ||

| Start Add + 6 | Reserved | ||

| <Table 8> Data saving address and contents for M_FLAG read command | |||

| Data Saving Address | Contents |

Data type | Remarks |

| Start Add + 0 | 0 ~ 5 Bit : Reserved(0) 6 Bit : Flag, 7 Bit : Flag, |

BYTE | Short Status ( equal with <Table 2 > ) |

| Start Add + 1 | Product ID ( always 4 ) |

6 Bit (0 ~ 64) | |

| Start Add + 2 | Version |

4 Bit (0 ~ 16 ) | |

| Start Add + 3 | Division Code |

6 Bit (0 ~ 64 ) | |

| Start Add + 4 | Discharge Pressure |

WORD (0 ~ 9999) |

|

| Start Add + 5 | Oil Pressure |

|

|

| Start Add + 6 | 1st Stage Pressure |

|

|

| Start Add + 7 | 1st Stage Temperature |

|

|

| Start Add + 8 | Oil Temperature |

|

|

| Start Add + 9 | Discharge Temperature |

|

|

| Start Add + 10 ~ 11 | Vibration Stage 1 ~ 2 |

X 100 |

|

| Start Add + 12 | Run Time |

DWORD (3BYTE) | save also at DWORD Start Add + 12 |

| Start Add + 13 | Reserved |

WORD |

|

| <Table 9> Data saving address and contents for M_ANA read command | |||

| Data Saving Address | Contents |

Data type | Remarks |

| Start Add + 0 | 0 ~ 5 Bit : Reserved ( 0 ) 6 Bit : Flag, 7 Bit : Flag, |

BYTE | Short Status ( equal with <Table 2 >) |

| Start Add + 1 | Product ID ( always 4 ) |

6 Bit (0 ~ 64) | |

| Start Add + 2 | Version |

4 Bit (0 ~ 16 ) | |

| Start Add + 3 | Division Code |

6 Bit (0 ~ 64 ) | |

| Start Add + 4 ~ 5 | Discharge Pressure High, Low |

WORD (0 ~ 9999) |

|

| Start Add + 6 ~ 7 | Oil Pressure Shutdown, Alert |

|

|

| Start Add + 8 ~ 9 | 1st Stage Temp Shutdown, Alert |

|

|

| Start Add + 10 ~ 11 | Oil Temp Shutdown, Alert |

|

|

| Start Add + 12 ~ 13 | Discharge Temp Shutdown, Alert |

|

|

| Start Add + 14 ~ 15 | Vibration Stage 1 Shutdown, Alert |

X 100 |

|

| Start Add + 16 ~ 17 | Vibration Stage 2 Shutdown, Alert |

||

| Start Add + 18 | Run Time |

DWORD (3BYTE) | save also at DWORD Start Add + 18 |

| Start Add + 19 | Dip Switch |

WORD |

|

| <Table 10> Data saving address and contents for M_SET read command | |||

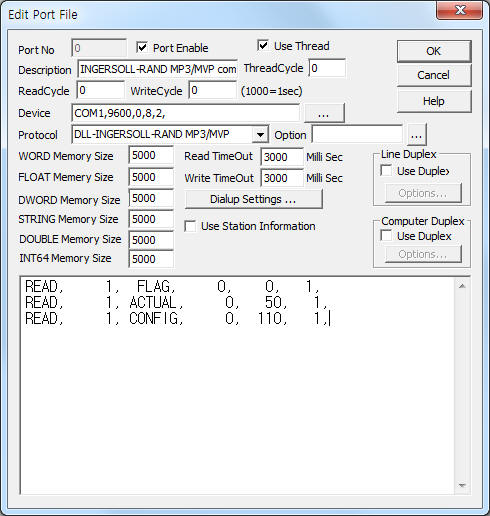

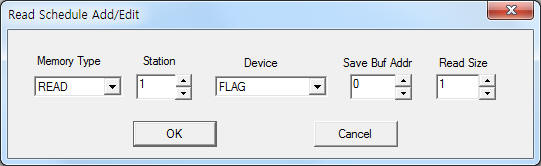

If you click the icon ![]() in protocol option part, you

can see the dialogue box such as <Figure 2>. you can also set read schedule by

using this part.

in protocol option part, you

can see the dialogue box such as <Figure 2>. you can also set read schedule by

using this part.

|

| <Figure 2> Example of INGERSOLL-RAND MP3/MVP communication driverí»s Option dialog box |

You can set read schedule by using ![]() ,

, ![]() ,

, ![]() button and listbox of <Figure

2>.

button and listbox of <Figure

2>.

|

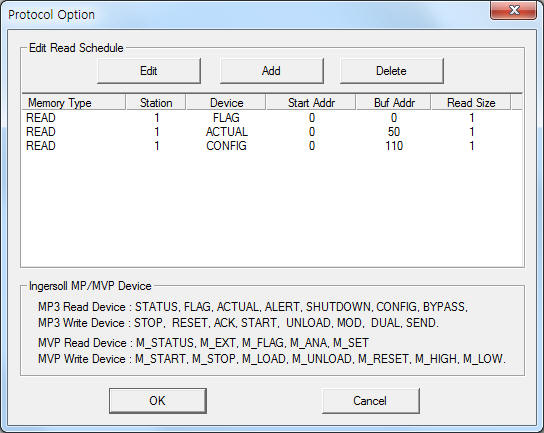

| <Figure 3> Example of INGERSOLL-RAND MP3/MVP communication driverí»s read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialogue box of <Figure 2>, dialogue box of <Figure 3> is shown.

You can control compressor by using 'writing settings'.

Digital Write

Digital write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION 0 ~ 4095 network address of PONI card.

3) ADDRESS Writing data type when SEND write command.

001E : Setting of System Pressure Setpoint,

001F : Setting of Current Limit High,

0020 : Setting of Current Limit Low,

0021 : Setting of Proportional Band,

0022 : Setting of Integral Time,

0023 : Setting of Setpoint Ramp Rate,

0024 : Setting of Reload Percent,

0064 : Setting of Unload Point,

00A4 : Setting of Unload Delay,

0025 : Setting of P1,

002D : Setting of Language,

002E : Setting of Units.

4) Extra1 Write command = MP3 model – STOP, RESET, ACK, START, UNLOAD, MOD, DUAL, SEND, ( refer to <Table 11> )

MVP model - M_START, M_STOP, M_LOAD, M_UNLOAD, M_RESET, M_HIGH, M_LOW. ( refer to <Table 12> )

5) Extra2 Don't care.

<Table 11>, <Table 12> are write command and contents for MP3, MVP Model.

| Write command | Contents | ADDRESS | Output value |

| STOP | Stop Compressor | Don't care (fixed to 0000) | Don't care |

| RESET | Reset | ||

| ACK | Acknowledge | ||

| START | Start Compressor | ||

| UNLOAD | Unload | ||

| MOD | Modulate | ||

| DUAL | Auto-dual | ||

| SEND | Send Data | 001E,

001F, 0020, 0021, 0022, 0023, 0024, 0064, 00A4, 0025, 002D, 002E |

interger |

| <Table 11> Write command and contents for MP3 Model | |||

| Write command | Contents | Output value |

| M_START | Start Compressor | Don't care |

| M_STOP | Stop Compressor | |

| M_LOAD | Load | |

| M_UNLOAD | Unload | |

| M_RESET | Reset | |

| M_HIGH | Set Discharge Pressure High | float |

| M_LOW | Set Discharge Pressure Low | |

| <Table 12> Write command and contents for MVP Model | ||

Analog Write

Analog write and digital write have the same setting parameters except output value.

Write example 1)

PORT:0, station:1, ADDRESS:0000, Extra1: STOP, Extra2 : 0

The setting parameter shown above is compressor stop control example of 1 PONI card network address MP3 or MVP controller.

Write example 2)

PORT:0, station:1, ADDRESS:0000, Extra1: START, Extra2 : 0

The setting parameter shown above is compressor start control example of 1 PONI card network address MP3 or MVP controller.

Write example 3)

PORT:0, station:1, ADDRESS:001E, Extra1: SEND, Extra2 : 0

The setting parameter shown above is a setting example of System Pressure Setpoint value for 1 PONI card network address MP3 or MVP controller.

Write example 4)

PORT:0, station:1, ADDRESS:0020, Extra1: SEND, Extra2 : 0

The setting parameter shown above is a setting example of Current Limit Low value for 1 PONI card network address MP3 or MVP controller.

Write example 5)

PORT:0, station:2, ADDRESS:0000, Extra1: M_HIGH, Extra2 : 0

The setting parameter shown above is a setting example of Set Discharge Pressure High value for 2 PONI card network address MP3 or MVP controller.

Connection of communication cable and main power line are as follows.

Connection of communication cable

Please connect direct RS-232C communication cable to MINT BOX controller such as <Figure 4>.

<Figure 4> RS-232C communication cable connection example of communication cable between MINT BOX and computer.( refer to <Figure 5> )

MINT BOX (25 pin connector) computer side ( 9 pin connector )

2 connector (Tx : SD) ------------------------- Tx : SD ( 3 )

3 connector (Rx : RD) ------------------------- Rx : RD ( 2 )

7 connector (Ground) ------------------------- Ground( 5 )

<Figure 4> RS-232C communication cable connection example of communication cable between MINT BOX and computer

|

| <Figure 5> Connection example of communication cable and main power to MINT BOX |

Connection of main power

Please connect 110V AC main power to main power connector of INGERSOLL-RAND MP3, MVP and MINT BOX controller.

<Figure 6> is appearance of PONI card controller.

<Figure 7> is appearance of PONI card and MP3 controller.

|

| <Figure 6> Appearance of PONI card controller |

|

| <Figure 7> Appearance of PONI card and MP3 controller |