IHI Turbo Compressor communication driver is the driver to communicate with compressor controller of Ishkawajima Heavy Industries Co., Ltd. in Japan.

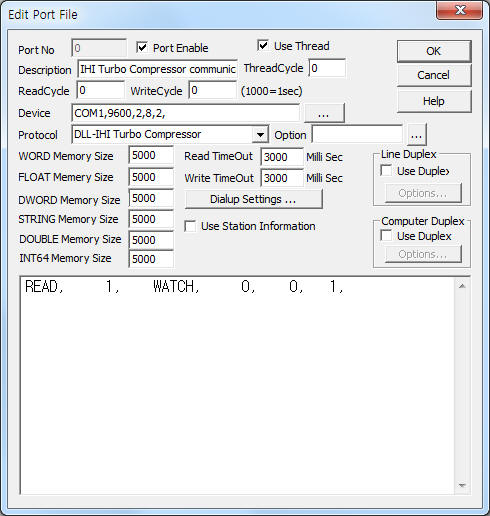

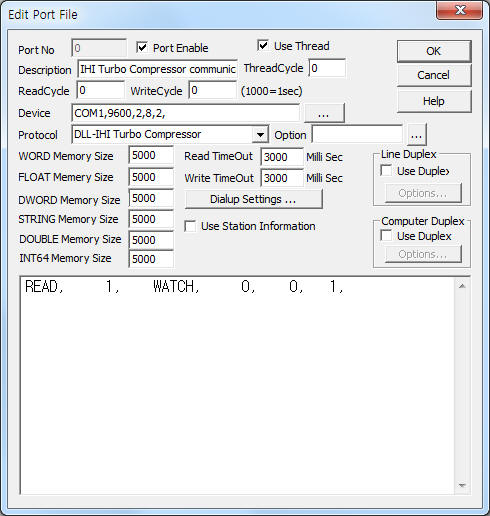

<Figure 1> is read setting example of IHI Turbo Compressor communication driver.

|

| <Figure 1> Read setting example of IHI Turbo Compressor communication driver |

Device part of <Figure 1> input Com Port(COM1), Baud Rate(9600), Parity Bit(2), Data Bit(8), Stop Bit(2) respectively, according to controller.

IHI Turbo Compressor communication driver read schedule

Read schedule setting parameters are as follows:

1) Station – Don't care.

2) Read command – Command = WATCH, RECALL, TEST. ( refer to <Table 1> )

3) Read Start Address – Don't care(fixed to 0).

4) Save start address for Communication Server – Saving start address of Communication Server. ( refer to <Table 1> )

5) Read Size – Fixed to 1.

Read schedule example)

READ, 1, WATCH, 0, 0, 1,

<Table 1> is read command and contents of IHI Turbo Compressor communication driver.

| Read command | Contents | Data Saving Address |

| WATCH | Read of watching data | refer to <Table 2> |

| RECALL | Read of recall data | refer to <Table 3> |

| TEST | Communication test | Start Add + 0 : success = 1, other(fail, ... ) = 0 |

| <Table 1> Read command and contents of IHI Turbo Compressor communication driver | ||

<Table 2>, <Table 3> are data saving address and contents for WATCH, RECALL read command.

| Data Saving Address | Contents | Data value or unit |

| Start Add + 0 ~ 2 | current year, month, day | |

| Start Add + 3 | current day of the week | 0 = sunday, 1 = monday, °¶, 6 = saturday |

| Start Add + 4 ~ 6 | current hour, minute, second | |

| Start Add + 7 | Compressor Type | 0 = TRE, 5 = TA, 9 = Tx, 99 = Other |

| Start Add + 8 | Operation Place | 1 = Local, 2 = Remote, 2 = Schedule |

| Start Add + 9 | IGV Open/Close | 0 = Fix, 1 = IGV Open, 2 = IGV Close |

| Start Add + 10 | Blow-Off Value(BV) Open/Close | 0 = Open, 1 = Close |

| Start Add + 11 | Compressor Status | 0 = Stop, 2 = Starting, 3 = Running, 4 = Ready for Stop |

| Start Add + 12 | Loading Status | 0 = Unload, 1 = Loading, 2 = Fix Unload, 3 = Fix Full Load, 4 = Forced Unload, 5 = IGV Manual Mode |

| Start Add + 13 | Ready to Run | 0 = Start Prep. Off, 1 = Prep. To Start, 2 = Ready to Run, 3 = Running, 4 = CO-OPE Starting, 5 = Cool Down |

| Start Add + 14 | Discharge Press(System Press) | kPa , 2 BYTE(WORD) data |

| Start Add + 15 | Discharge Press(Compressor Press) | |

| Start Add + 16 | Main Motor Current | 0.1 A , 2 BYTE(WORD) data |

| Start Add + 17 ~ 18 | Lub. Oil Press. Low/High Side | kPa , 2 BYTE(WORD) data |

| Start Add + 19 | Lub. Oil Filter Differencial Press | |

| Start Add + 20 | Lub. Oil Temp.(Oil Cooler Outlet) | 0.1 °… , 2 BYTE(WORD) data |

| Start Add + 21 | 2nd Stage Inlet Air Temp. | |

| Start Add + 22 | Final Stage Inlet Air Temp. | |

| Start Add + 23 ~ 26 | 1st, 2nd, 3rd, 4th Shaft Vibration | 0.1 µ m , 2 BYTE(WORD) data |

| Start Add + 27 | Suction Air Filter Differencial Press | Pa , 2 BYTE(WORD) data |

| Start Add + 28 | Discharge Air Temp. | 0.1 °… , 2 BYTE(WORD) data |

| Start Add + 29 | Cooling Water Inlet Temp. | |

| Start Add + 30 ~ 32 | Inter-Cooer, Oil-Cooler, After-Cooler Outlet Cooling Water Temp. | |

| Start Add + 33 ~ 34 | IGV, Blow-Off Positioner Signal | 0.1 % , 2 BYTE(WORD) data |

| Start Add + 35 | Remote Const. Press Set Point | kPa , 2 BYTE(WORD) data |

| Start Add + 36 | Discharge Press for Anti-Surge Press Control | |

| Start Add + 37 ~ 38 | Reserved | 2 BYTE(WORD) data |

| Start Add + 39 | Running Hour | Hour, 4 BYTE(DWORD) data |

| Start Add + 40 | Start Times | Time, 4 BYTE(DWORD) data |

| Start Add + 41 | Loading Hour | Hour, 4 BYTE(DWORD) data |

| Start Add + 42 | Loading Times | Time, 4 BYTE(DWORD) data |

| Start Add + 43 | Low Side Lub. Oil Press Lower Limit | kPa, 2 BYTE(WORD) data |

| Start Add + 44 | High Side Lub. Oil Press Lower Limit | |

| Start Add + 45 | Lub. Oil Temp. Higher Limit | 0.1 % , 2 BYTE(WORD) data |

| Start Add + 46 | Each Stage Inlet Air Temp. Higher Limit | |

| Start Add + 47 | Each Stage Shaft Vib. Higher Limit | 0.1 µ m , 2 BYTE(WORD) data |

| Start Add + 48 | Discharge Air Temp. Higher Limit | 0.1 % , 2 BYTE(WORD) data |

| Start Add + 49 | Cooling Water Inlet Temp. Higher Limit | |

| Start Add + 50 | Const. Press Control Set Point | kPa, 2 BYTE(WORD) data |

| Start Add + 51 | Unloading Discharge Press (H) Set Point | |

| Start Add + 52 | Loading Discharge Press (L) Set Point | |

| Start Add + 53 | Main Motor Anti-Overload Current Set Point | 0.1 A , 2 BYTE(WORD) data |

| Start Add + 54 | Anti-Surge Lower Limit Current | |

| Start Add + 55 | Anti-Surge Press Control Set Point | kPa, 2 BYTE(WORD) data |

| Start Add + 56 | Reserved | 1 BYTE data |

| Start Add + 57 | Aux. Equipments Status | Bit 0 : Aux. Oil Pump Status(On = Running, Off = Stop), Bit 1 : Lub. Oil Heater On, Bit 2 : Lub. Oil Heater Off, Bit 3 : Exhoust Fan Running, Bit 4 : Exhoust Fan Stop, Bit 5 : Ventilation Fan Running, Bit 6 : Ventilation Fan Stop, Bit 7 : Reserved, 1 BYTE data |

| Start Add + 58 | Heavy Troubles(TRIP) 1 | refer to IHI Compressor reference manual, 2 BYTE(WORD) data |

| Start Add + 59 | Heavy Troubles(TRIP) 2 | |

| Start Add + 60 | Light Troubles(ALARM) 1 | |

| Start Add + 61 | Light Troubles(ALARM) 2 | |

| Start Add + 62 | Maintain 1 | |

| Start Add + 63 | Maintain 2 | |

| <Table 2> Data saving address and contents for WATCH read command | ||

| Data Saving Address | Contents | Data value or unit |

| Start Add + 0 ~ 2 | current year, month, day | |

| Start Add + 3 | current day of the week | 0 = sunday, 1 = monday, °¶, 6 = saturday |

| Start Add + 4 ~ 6 | current hour, minute, second | |

| Start Add + 7 | Compressor Type | 0 = TRE, 5 = TA, 9 = Tx, 99 = Other |

| Start Add + 8 | Operation Place | 1 = Local, 2 = Remote, 2 = Schedule |

| Start Add + 9 | IGV Open/Close | 0 = Fix, 1 = IGV Open, 2 = IGV Close |

| Start Add + 10 | Blow-Off Value(BV) Open/Close | 0 = Open, 1 = Close |

| Start Add + 11 | Compressor Status | 0 = Stop, 2 = Starting, 3 = Running, 4 = Ready for Stop |

| Start Add + 12 | Loading Status | 0 = Unload, 1 = Loading, 2 = Fix Unload, 3 = Fix Full Load, 4 = Forced Unload, 5 = IGV Manual Mode |

| Start Add + 13 | Ready to Run | 0 = Start Prep. Off, 1 = Prep. To Start, 2 = Ready to Run, 3 = Running, 4 = CO-OPE Starting, 5 = Cool Down |

| Start Add + 14 | Discharge Press(System Press) | kPa , 2 BYTE(WORD) data |

| Start Add + 15 | Discharge Press(Compressor Press) | |

| Start Add + 16 | Main Motor Current | 0.1 A , 2 BYTE(WORD) data |

| Start Add + 17 ~ 18 | Lub. Oil Press. Low/High Side | kPa , 2 BYTE(WORD) data |

| Start Add + 19 | Lub. Oil Filter Differencial Press | |

| Start Add + 20 | Lub. Oil Temp.(Oil Cooler Outlet) | 0.1 °… , 2 BYTE(WORD) data |

| Start Add + 21 | 2nd Stage Inlet Air Temp. | |

| Start Add + 22 | Final Stage Inlet Air Temp. | |

| Start Add + 23 ~ 26 | 1st, 2nd, 3rd, 4th Shaft Vibration | 0.1 µ m , 2 BYTE(WORD) data |

| Start Add + 27 | Suction Air Filter Differencial Press | Pa , 2 BYTE(WORD) data |

| Start Add + 28 | Discharge Air Temp. | 0.1 °… , 2 BYTE(WORD) data |

| Start Add + 29 | Cooling Water Inlet Temp. | |

| Start Add + 30 ~ 33 | Inter-Cooer, Oil-Cooler, After-Cooler Outlet Cooling Water Temp. | |

| Start Add + 34 ~35 | IGV, Blow-Off Positioner Signal | 0.1 % , 2 BYTE(WORD) data |

| Start Add + 36 | Remote Const. Press Set Point | kPa , 2 BYTE(WORD) data |

| Start Add + 37 | Discharge Press for Anti-Surge Press Control | |

| Start Add + 38 | Reserved | 2 BYTE(WORD) data |

| Start Add + 39 | Running Hour | Hour, 4 BYTE(DWORD) data |

| Start Add + 40 | Start Times | Time, 4 BYTE(DWORD) data |

| Start Add + 41 | Loading Hour | Hour, 4 BYTE(DWORD) data |

| Start Add + 42 | Loading Times | Time, 4 BYTE(DWORD) data |

| Start Add + 43 ~ 45 | Heavy Trouble occur hour, minute, second | when Heavy Trouble alarm |

| Start Add + 46 | Heavy Trouble occur day of the week | when Heavy Trouble alarm 0 = sunday, 1 = monday, °¶, 6 = saturday |

| Start Add + 47 ~ 49 | Heavy Trouble occur hour, minute, second | when Heavy Trouble alarm |

| Start Add + 50 | Heavy Troubles(TRIP) 1 | refer to IHI Compressor reference manual, 2 BYTE(WORD) data |

| Start Add + 51 | Heavy Troubles(TRIP) 2 | |

| <Table 3> Data saving address and contents for RECALL read command | ||

IHI Turbo Compressor communication driver store the same data in WORD, DWORD, FLOAT memory, but the data format are different.

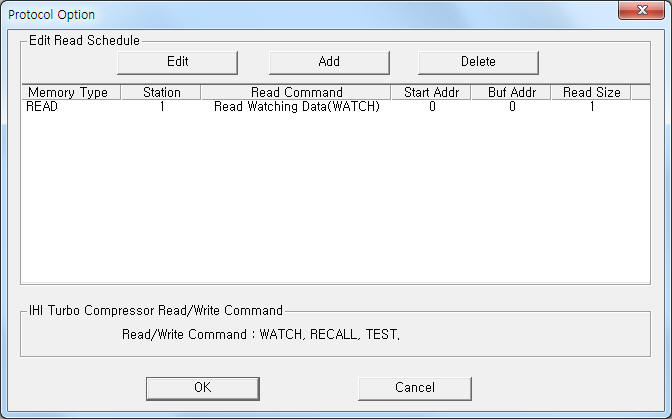

If you click the icon ![]() in protocol option part, you

can see the dialogue box such as <Figure 3>. you can also set read schedule by

using this part.

in protocol option part, you

can see the dialogue box such as <Figure 3>. you can also set read schedule by

using this part.

|

| <Figure 2> Example of IHI Turbo Compressor communication driver°Įs Option dialog box |

You can set read schedule by using ![]() ,

, ![]() ,

, ![]() button and listbox of <Figure

2>.

button and listbox of <Figure

2>.

|

| <Figure 3> Example of IHI Turbo Compressor communication driver°Įs read schedule Add/Edit dialog box |

When you click Add button or Edit button in dialogue box of <Figure 2>, dialogue box of <Figure 3> is shown.

You can read data by using 'writing settings'.

Digital Write

Digital write and analog write have the same setting parameters except output value(0 or 1).

Analog Write

Analog write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION Don't care.

3) ADDRESS Saving address for readed data. ( decimal unit )

4) Extra1 Command = WATCH, RECALL, TEST. ( refer to <Table 1> )

5) Extra2 Don't care.

Write example 1)

PORT:0, station:0, ADDRESS:0250, Extra1: RECALL, Extra2 :

The setting parameter shown above is a 'RECALL' read command example. After write command, the readed data save from 250 address WORD, DWORD, FLOAT memory.

Block Write

IHI Turbo Compressor communication driver don't support 'Block Write'.