HYDRAN 201Ti communication driver is the driver to communicate with Intelligent Transmitter of General Electric Canada Inc. in Canada.

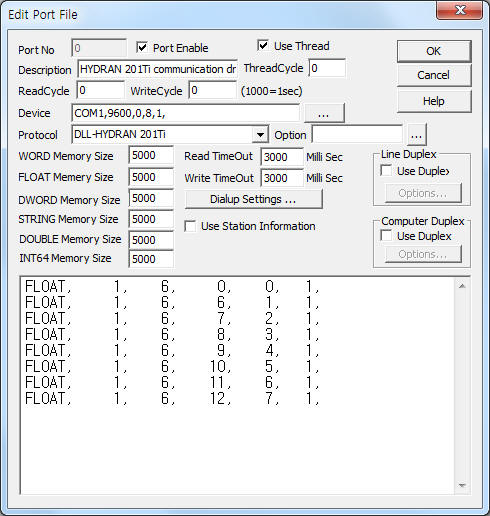

<Figure 1> is read setting example of HYDRAN 201Ti communication driver.

|

| <Figure 1> Read setting example of HYDRAN 201Ti communication driver |

Device part of <Figure 1> input Com Port(COM1), Baud Rate(9600), Parity Bit(0), Data Bit(8), Stop Bit(1) respectively, according to setting of controller.

Note) HYDRAN 201Ti controller can set baud rate between 2400, 4800, 9600, also parity bit, data bit, stop bit are fixed to 0, 8, 1.

HYDRAN 201Ti communication driver read schedule

Read schedule setting parameters are as follows:

1) Station – 0 ~ 254 controller station(address) number. 0 = Nobody Listens, 255 = Everybody listens(broadcast).

2) Read command – Command = 0 ~ 31. refer to <Table 1>.

3) Read Start Address – Reading start address(decimal unit) according to 'read command'. refer to <Table 2>, <Table 3>.

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read Size – Fixed to 1.

Read schedule example)

FLOAT, 1, 6, 0, 0, 1,

FLOAT, 1, 6, 6, 1, 1,

FLOAT, 1, 6, 7, 2, 1,

FLOAT, 1, 6, 8, 3, 1,

FLOAT, 1, 6, 9, 4, 1,

FLOAT, 1, 6, 10, 5, 1,

FLOAT, 1, 6, 11, 6, 1,

FLOAT, 1, 6, 12, 7, 1,

<Table 1> is command number and contents of HYDRAN 201Ti communication driver.

<Table 2>, <Table 3> are data number and contents of System Variable(5, 6 command), System Boolean(7, 8 command).

Command number |

Contents |

Remarks |

0 |

Null command |

for connection test command |

1 ~ 4 |

Command for General Electric Canada |

|

5 |

Write of System Variable, refer to data number of <Table 2> |

analog write |

6 |

Read of System Variable, refer to data number of <Table 2> |

read |

7 |

Write of System Boolean |

digital wirite |

8 |

Read of System Boolean |

|

9 ~ 10 |

Command for General Electric Canada |

|

11 |

Read of Histo Record |

|

12 |

Next Histo Record |

|

13 |

Previous Histo Record |

|

14 |

Histo Start Date |

|

15 |

Rewind Histo Files |

|

16 |

Force Sensor Test |

|

17 |

Alarm Recognized |

|

18 ~ 19 |

Command for General Electric Canada |

|

20 |

Status |

|

21 |

Clear Histo |

|

22 |

Command for General Electric Canada |

|

23 |

Read of Date/Time |

|

24 |

Write of Date/Time |

|

25 ~ 26 |

Command for General Electric Canada |

|

27 |

End of Transmits |

|

28 |

New Sensor |

|

29 |

System Status Asked from the Remote Host Computer |

|

30 |

Clear One of the Four Histo |

|

31 |

Command for General Electric Canada |

|

| <Table 1> Command number and contents of HYDRAN 201Ti communication driver | ||

Data number |

Contents |

Min range |

Max range |

0 |

Gas ppm value |

0 |

0 |

1 ~ 2 |

Hourly/Daily Trend |

0 |

0 |

3 |

Sensor Temperature |

0 |

0 |

4 |

Battery Voltage |

0 |

0 |

5 |

Sensor Test Result |

0 |

0 |

6 ~ 7 |

Gas Set-Point Low Low/Low |

0 |

2000 |

8 ~ 9 |

Gas Set-Point High/High High |

0 |

2000 |

10 ~ 11 |

Hourly Set-Point Low Low/Low |

-99.9 |

99.9 |

12 ~ 13 |

Hourly Set-Point High/High High |

-99.9 |

99.9 |

14 ~ 15 |

Daily Set-Point Low Low/Low |

-2000 |

2000 |

16 ~ 17 |

Daily Set-Point High/High High |

-2000 |

2000 |

18 ~ 19 |

Sensor Temperature Set-Point Low Low/Low |

-40 |

90 |

20 ~ 21 |

Sensor Temperature Set-Point High/High High |

-40 |

90 |

22 |

Battery Set-Point Low Low |

1.7 |

3.0 |

23 |

Battery Set-Point Low |

1.8 |

3.0 |

24 |

Battery Set-Point High |

0 |

4 |

25 |

Set-up Lost(version 2.2) |

-1 |

-7 |

30 |

Gas Alarm Delay |

0 |

300 |

31 ~ 31 |

Hourly/Daily Trend Alarm Delay |

0 |

300 |

35 |

Sensor Test Alarm Delay |

0 |

300 |

36 |

Period B |

0 |

250 |

37 |

Hourly Trend Period |

0.1 |

99.9 |

38 |

Daily Trend Period |

1 |

99 |

39 |

Histo Short-term Ramte(minute) |

1 |

360 |

40 |

heating Plate Temperature( ¡É ) |

0 |

0 |

41 |

Service¥° |

0 |

0 |

42 |

Service A |

0 |

0 |

43 |

Heater Power |

0 |

0 |

60 |

General Histo Year |

1994 |

2094 |

61 |

General Histo Month |

1 |

12 |

62 |

General Histo Day |

1 |

31 |

63 |

General Histo Hour |

0 |

23 |

64 |

General Histo Minute |

0 |

59 |

67 ~ 68 |

Gas High/High High Relay Mode |

0 |

3 |

69 |

System OK Relay Mode |

0 |

3 |

70 |

Sensor Temperature Set-point |

0 |

45 |

71 |

Sensor Temperature Modulation |

0 |

10 |

72 |

Period A |

1 |

300 |

74 ~ 83 |

Cell b/m/n/s/a1/a2/a3/a4/a5/a6 |

-32767 |

32768 |

94 |

Sensor Serial Number |

0 |

1000000 |

95 |

Program Revision |

0 |

0 |

96 |

Please Wait |

0 |

1 |

101 ~ 102 |

Service V/U |

0 |

1 |

106 |

H201Ti ID(do not overwrite) |

1 |

254 |

107 |

Power Station ID(do not overwrite) |

1 |

9999 |

108 |

Baud Rate(do not overwrite) |

0 |

3 |

109 |

Actual Computed Temperature Set-point |

0 |

0 |

114 ~ 115 |

Long-term Log Point No. 1 Hour/Minute |

0 |

23/59 |

116 ~ 117 |

Long-term Log Point No. 2 Hour/Minute |

0 |

23/59 |

118 ~ 119 |

Long-term Log Point No. 3 Hour/Minute |

0 |

23/59 |

120 ~ 121 |

Long-term Log Point No. 4 Hour/Minute |

0 |

23/59 |

122 ~ 123 |

Hourly/Daily Trend Alarm Delay Percent |

0 |

100 |

126 |

Analog Mode |

0 |

3 |

127 |

TDM Mode |

0 |

3 |

128 |

Analog Status |

0 |

0 |

129 |

TDM Status |

0 |

0 |

130 |

Comm Mode(do not overwrite) |

0 |

1 |

131 |

Cell Parameters Check-sum |

0 |

99999 |

133 |

Sensor Test Result |

0 |

0 |

141 |

Service F |

0 |

0 |

144 |

Full Scale(in ppm) |

0 |

50000 |

| <Table 2> Data number and contents of System Variable(5, 6 command) | |||

Data number |

Contents |

0 ~ 1 |

Gas Set-Point Low Low/Low Active |

2 ~ 3 |

Gas Set-Point High/High High Active |

4 ~ 5 |

Hourly Set-Point Low Low/Low Active |

6 ~ 7 |

Hourly Set-Point High/High High Active |

8 ~ 9 |

Daily Set-Point Low Low/Low Active |

10 ~ 11 |

Daily Set-Point High/High High Active |

12 ~ 13 |

Sensor Temperature Set-Point Low Low/Low Active |

14 ~ 15 |

Sensor Temperature Set-Point High/High High Active |

16 ~ 17 |

Battery Set-Point Low Low/Low Active |

18 |

Battery Set-Point High Active |

24 ~ 25 |

Gas Set-Point Low Low/Low Fault Trigger |

26 ~ 27 |

Gas Set-Point High/High High Fault Trigger |

28 ~ 29 |

Hourly Set-Point Low Low/Low Fault Trigger |

30 ~ 31 |

Hourly Set-Point High/High High Fault Trigger |

32 ~ 33 |

Daily Set-Point Low Low/Low Fault Trigger |

34 ~ 35 |

Daily Set-Point High/High High Fault Trigger |

36 ~ 37 |

Sensor Temperature Set-Point Low Low/Low Fault Trigger |

38 ~ 39 |

Sensor Temperature Set-Point High/High High Fault Trigger |

40 ~ 41 |

Battery Set-Point Low Low/Low Fault Trigger |

43 |

Set-up Lost Fault Trigger(version 2.2) |

44 |

Sensor Test Set Short Cable Fault Trigger |

45 |

Sensor Test Replace Sensor Soon Fault Trigger |

46 |

Sensor Test Replace Sensor Now Fault Trigger |

47 |

Sensor Test Open Cable Fault Trigger |

48 ~ 50 |

Historic Long-term Log Point No.2 ~ 4 Active |

| <Table 3> Data number and contents of System Boolean(7, 8 command) | |

HYDRAN 201Ti communication driver store the same data in WORD, DWORD, FLOAT memory, but the data format are different.

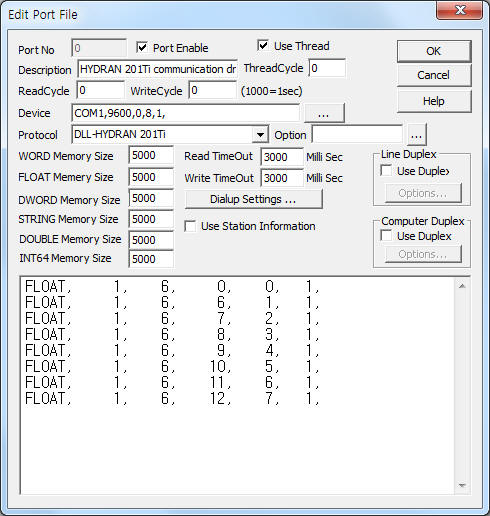

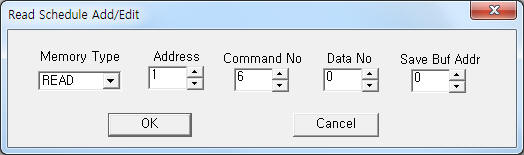

If you click the icon ![]() in protocol option part, you

can see the dialogue box such as <Figure 2>. you can also set read schedule by

using this part.

in protocol option part, you

can see the dialogue box such as <Figure 2>. you can also set read schedule by

using this part.

|

| <Figure 2> Example of HYDRAN 201Ti communication driver¡¯s Option dialogue box |

You can set read schedule by using ![]() ,

, ![]() ,

, ![]() button and listbox of <Figure

2>.

button and listbox of <Figure

2>.

|

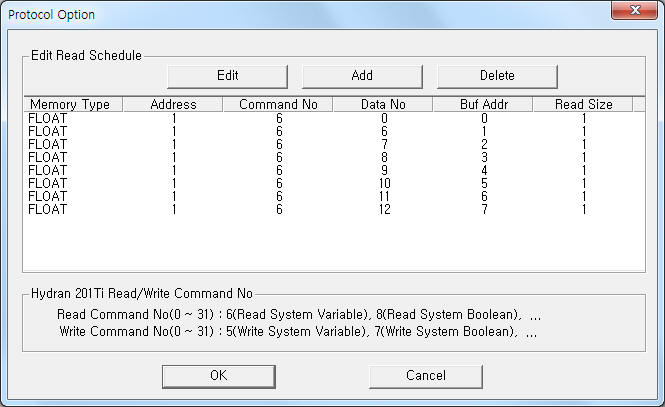

| <Figure 3> Example of HYDRAN 201Ti communication driver¡¯s read schedule Add/Edit dialogue box |

When you click Add button or Edit button in dialogue box of <Figure 2>, dialogue box of <Figure 3> is shown.

You can set HYDRAN 201Ti controller by using write settings

Digital Write

Digital write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION 0 ~ 254 controller station(address) number. 0 = Nobody Listens, 255 = Everybody listens(broadcast).

3) ADDRESS Decimal unit reading or writing address according to Extra1. ( refer to <Table 2>, <Table 3> )

4) Extra1 Read/Write command = 0 ~ 31. (refer to <Table 1> ) Default command = 7.

5) Extra2 Don't care.

Write example 1)

PORT:0, station:1, ADDRESS:0000, Extra1: 7, Extra2 :

The setting parameter shown above is 'Gas Set-point Low Low Active status'( refer to <Table 3> ) control(0 = OFF, 1 = ON) example of 1 station HYDRAN 201Ti controller.

Write example 2)

PORT:0, station:1, ADDRESS:0001, Extra1: 7, Extra2 :

The setting parameter shown above is 'Gas Set-point Low Active status'( refer to <Table 3> ) control(0 = OFF, 1 = ON) example of 1 station HYDRAN 201Ti controller.

Analog Write

Analog write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION 0 ~ 254 controller station(address) number. 0 = Nobody Listens, 255 = Everybody listens(broadcast).

3) ADDRESS Decimal unit reading or writing address according to Extra1. ( refer to <Table 2>, <Table 3> )

4) Extra1 Read/Write command = 0 ~ 31. (refer to <Table 1> ) Default command = 5.

5) Extra2 Decimal point. ( 0 = 2 decimal point )

Write example 1)

PORT:0, station:1, ADDRESS:0000, Extra1: 5, Extra2 :

The setting parameter shown above is 'Gas ppm value'( refer to <Table 3> ) setting(2 decimal point unit) example of 1 station HYDRAN 201Ti controller.

Write example 2)

PORT:0, station:1, ADDRESS:0006, Extra1: 5, Extra2 :

The setting parameter shown above is 'Hourly Set-Point High Active'( refer to <Table 3> ) setting(2 decimal point unit) example of 1 station HYDRAN 201Ti controller.

Connection of communication cable and main power line are as follows.

Connection of communication cable

Please connect normal RS-232C(cross) communication cable to 9 pin connector of HYDRAN 201Ti controller such as <Figure 4>.

|

| <Figure 4> Connection example of main power and communication cable to HYDRAN 201T controller |

Connection of main power

Please connect 230(220)V AC main power to L, N connector.

<Figure 5> is appearance of HYDRAN 201Ti controller.

|

| <Figure 5> Appearance of HYDRAN 201Ti controller |