ECU-09 Micom Controller communication driver is the driver to communicate with temperature chamber controller of Nemo Engineering. in Korea.

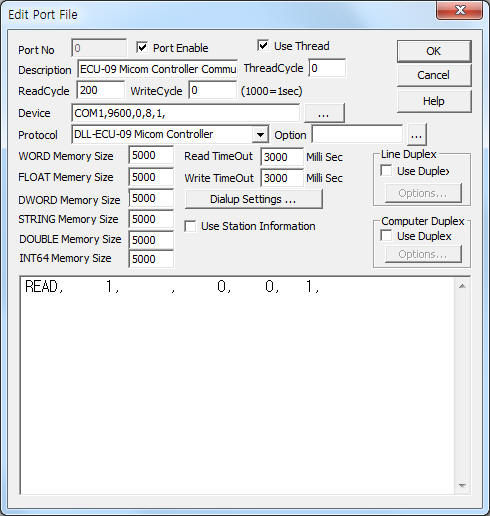

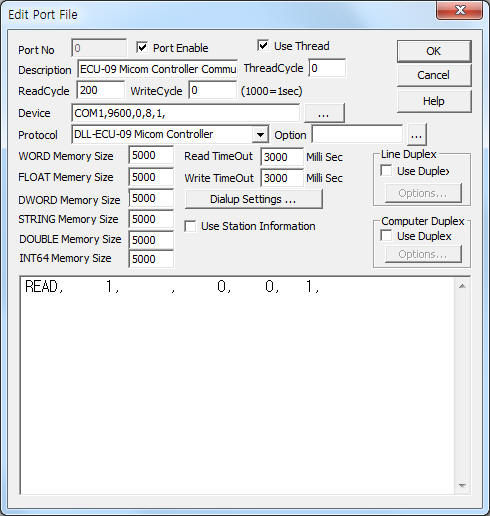

<Figure 1> is read setting example of ECU-09 Micom Controller communication driver.

|

| <Figure 1> Read setting example of ECU-09 Micom Controller communication driver |

Device part of <Figure 1> input Com Port(COM1), Baud Rate(fixed to 9600), Parity Bit(0), Data Bit(8), Stop Bit(1) respectively, according to setting of controller.

Note) Please set the 'read cycle' more than 200(mSec unit). If you set under 200, the keypad of temperature chamber controller does not operate normally.

ECU-09 Micom Controller communication driverí»s read schedule

Read schedule setting parameters are as follows:

1) Station – Controller station number = 1 ~ 32.

2) Read Type – Don't care.

3) Read Start Address – Don't care.

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read Size – fixed to 1. ( Refer to <Table 1> )

Read schedule example)

READ, 1, , 0, 0, 1,

<Table 1> is data saving address and contents of ECU-09 Micom Controller communication driver.

| Data Saving Address | Contents | Remarks | |

| When 2 compressor | When 3 compressor | ||

| Start Add + 0 | Ooperation status of temperature chamber controller | BIT0 : operation status | |

| Start Add + 1 | Current temperature | Real value = read value / 2 | |

| Start Add + 2 | Setting temperature | Real value = read value / 2 | |

| Start Add + 3 | Induction temperature | Real value = read value / 2 | |

| Start Add + 4 | Current humidity | Real value = read value / 2 | |

| Start Add + 5 | Setting humidity | Real value = read value / 2 | |

| Start Add + 6 | Induction humidity | Real value = read value / 2 | |

| Start Add + 7 | Operation delay time of compressor | ||

| Start Add + 8 | High alarm setting temperature | Real value = read value / 2 | |

| Start Add + 9 | Start time of drainage | ||

| Start Add + 10 | Stop delay time of air blower | ||

| Start Add + 11 | Don't care | ||

| Start Add + 12 | Restart time of equipment | ||

| Start Add + 13 | Auto alternation time of compressor | ||

| Start Add + 14 | Don't care | ||

| Start Add + 15 | Operation status of FAN OUT | BIT0 : operation status | |

| Start Add + 16 | Don't care | ||

| Start Add + 17 | Operation status of compressor 1 | BIT0 : operation status | |

| Start Add + 18 | Don't care | ||

| Start Add + 19 | Operation status of compressor 2 | BIT0 : operation status | |

| Start Add + 20 | Operation status of heater 1 | BIT0 : operation status | |

| Start Add + 21 | Operation status of heater 2 | BIT0 : operation status | |

| Start Add + 22 | Operation status of heater 3 | BIT0 : operation status | |

| Start Add + 23 | Operation status of heater 4 | BIT0 : operation status | |

| Start Add + 24 | Operation status of heater 5 | Operation status of compressor 3 | BIT0 : operation status |

| Start Add + 25 | Operation status of humidification 1 | BIT0 : operation status | |

| Start Add + 26 | Operation status of humidification 2 | BIT0 : operation status | |

| Start Add + 27 | Operation status of watering | BIT0 : operation status | |

| Start Add + 28 | Operation status of drainage | BIT0 : operation status | |

| Start Add + 29 | Operation status of cooling | BIT0 : operation status | |

| Start Add + 30 | Operation status of dehumidification | BIT0 : operation status | |

| Start Add + 31 | Abnormal of FAN | BIT0 : operation status | |

| Start Add + 32 | Abnormal of compressor 1 | BIT0 : operation status | |

| Start Add + 33 | Abnormal of compressor 2 | BIT0 : operation status | |

| Start Add + 34 | Abnormal of heating | BIT0 : operation status | |

| Start Add + 35 | Abnormal of humidification | BIT0 : operation status | |

| Start Add + 36 | Abnormal of sensor | BIT0 : operation status | |

| Start Add + 37 | Abnormal of water leaks | Abnormal of compressor 3 | BIT0 : operation status |

| Start Add + 38 | High temperature status | BIT0 : operation status | |

| Start Add + 39 | Don't care | ||

| Start Add + 40 | Fire alarm | BIT0 : operation status | |

| Start Add + 41 | Abnormal of water sensing | BIT0 : operation status | |

| Start Add + 42 | Remote control operation | BIT0 : operation status | |

| Start Add + 43 | Don't care | ||

| <Table 1> Data Saving Address and contents of ECU-09 Micom Controller communication driver | |||

You can write the setting value by using write settings.

Digital Write

Digital write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION Controller station number = 1 ~ 32.

3) ADDRESS Don't care.

4) Extra1 Write command = CONT : control command.

5) Extra2 Don't care.

Write example 1)

Port : 0, Station : 1, Address : 0000, EXTRA1 : CONT, EXTRA2 : 0

The setting parameter shown above is a control(On/Off) example of 1 controller station number

Analog Write

Analog write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION Controller station number = 1 ~ 32.

3) ADDRESS Don't care.

4) Extra1 Write command.

TEMP : Increase(+) or decrease(-) of setting temperature,

STEMP : Increase(+) or decrease(-) of induction temperature,

HUMI : Increase(+) or decrease(-) of setting humidity,

SHUMI : Increase(+) or decrease(-) of induction humidity,

PUMDLY : Increase(+) or decrease(-) of compressor operation delay time,

ALMTEM : Increase(+) or decrease(-) of high temperature alarm setting,

FANDLY : Increase(+) or decrease(-) of fan delay stop time,

PUMEXC : Increase(+) or decrease(-) of compressor auto alternating hours.

5) Extra2 Don't care.

Write example 1)

Port : 0 Station : 1 Address : 0000 EXTRA1 : TEMP EXTRA2 : 0

The setting parameter shown above is a write example of setting temperature(increase or decrease).

Write example 2)

PORT : 0 STATION : 1 ADDRESS : 0000 EXTRA1 : STEMP EXTRA2 : 0

The setting parameter shown above is a write example of induction temperature(increase or decrease).

Write example 3)

PORT : 0 STATION : 1 ADDRESS : 0000 EXTRA1 : HUMI EXTRA2 : 0

The setting parameter shown above is a write example of setting humidity(increase or decrease).

Write example 4)

PORT : 0 STATION : 1 ADDRESS : 0000 EXTRA1 : SHUMI EXTRA2 : 0

The setting parameter shown above is a write example of induction humidity(increase or decrease).

Write example 5)

PORT : 0 STATION : 1 ADDRESS : 0000 EXTRA1 : PUMDLY EXTRA2 : 0

The setting parameter shown above is a write example of compressor operation delay time(increase or decrease).

Write example 6)

PORT : 0 STATION : 1 ADDRESS : 0000 EXTRA1 : ALMTEM EXTRA2 : 0

The setting parameter shown above is a write example of high temperature alarm setting(increase or decrease).

Write example 7)

PORT : 0 STATION : 1 ADDRESS : 0000 EXTRA1 : FANDLY EXTRA2 : 0

The setting parameter shown above is a write example of fan delay stop time(increase or decrease).

Write example 8)

PORT : 0 STATION : 1 ADDRESS : 0000 EXTRA1 : PUMEXC EXTRA2 : 0

The setting parameter shown above is a write example of compressor auto alternating hours(increase or decrease).

Connection of main power line and communication cable are as follows.

Connection of main power line

Please connect main power to connector AC, COM220, 220V AC.

Connection of communication cable

Please connect ECU-09 controllerí»s RS-485 X+,X- connector and computer's RS-485 +, - connector respectively.

ECU-09 controller's 485 connector Computer's RS-485 connector

X+ --------------------------------------------------- +

X- ---------------------------------------------------- -

<Figure 2> is connection example of main power line and RS-485 communication cable to ECU-09 controller.

|

| <Figure 2> Connection example of main power line and RS-485 communication cable to ECU-09 controller |