DONGA Hitech Smart RPPS Communication Driver is the driver to communicate with rectifier controller of Donga Hitech Co., Ltd. in Korea.

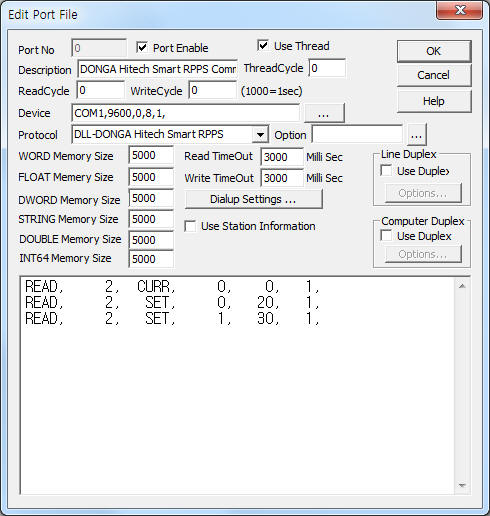

<Figure 1> is read setting example of DONGA Hitech Smart RPPS communication driver.

|

| <Figure 1> Read setting example of DONGA Hitech Smart RPPS communication driver |

Device part of <Figure 1> input Com Port(COM1), Baud Rate(9600, fixed), Parity Bit(0), Data Bit(8), Stop Bit(1) respectively, according to setting of controller.

DONGA Hitech Smart RPPS communication driverí»s read schedule

Read schedule setting parameters are as follows:

1) Station – Controller station number = 0 ~ 15.

2) Read Command – Command = CURR, SET. ( Refer to <Table 1> )

3) Read Start Address – 0 ~ 9 setp number when 'SET' read command, other command = Don't care.

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read Size – fixed to 1.

Read schedule example)

READ, 2, CURR, 0, 0, 1,

READ, 2, SET, 0, 20, 1,

READ, 2, SET, 1, 30, 1,

<Table 1> is data saving address and contents of CURR read command, <Table 2> is data saving address and contents of SET read command.

| Data Saving Address | Contents | Saving Data |

Remarks |

| Start Add + 0 | Status register | 0 Bit = rectifier ON(1)/Pause(0), 1 Bit = operation mode CC(1)/CV(0), 2 Bit = HIGH(1)/LOW(0) of CC mode |

|

| Start Add + 1 | Number of end step | 0 ~ 9 |

|

| Start Add + 2 | operation position/Fault exist, not exist | 0 Bit = operation position Local(1)/Remote(0), 1 Bit = Fault exist : 1/ not exist : 0, |

Read only |

| Start Add + 3 | Reset of watt-hour meter/after stop step 0 of rectifier | 0 Bit = Ah Reset, when 'On' Reset 1 Bit = after stop step 0 of rectifier(when 'On') |

Write only (when set 'On') |

| Start Add + 4 | Current step number | 0 ~ 9 setp number |

|

| Start Add + 5 | Time of step operation | Step operation time of second unit |

0 ~ 999999 |

| Start Add + 6 | Feedback Pos-Curr | Feedback Pos-Curr |

0 ~ 9999 |

| Start Add + 7 | Feedback Pos-Volt | Feedback Pos-Volt |

|

| Start Add + 8 | Feedback Neg-Curr | Feedback Neg-Curr |

|

| Start Add + 9 | Feedback Neg-Volt | Feedback Neg-Volt |

|

| Start Add + 10 | MAmp-Hour | Mamp-Hour |

Real value = current value/1000 |

| <Table 1> Data saving address and contents of CURR read command | |||

| Data Saving Address | Contents | Saving Data | Remarks |

| Start Add + 0 | Setting time of step operation | Setting time of second unit | 0 ~ 999999 |

| Start Add + 1 | Pos-Time | Pos-Time value(ms unit) | 1 ~ 9999 ms |

| Start Add + 2 | Neg-Time | Neg-Time value(ms unit) | 0 ~ 9999 ms |

| Start Add + 3 | Off-Time | Off-Time value(ms unit) | |

| Start Add + 4 | Pos-Volt | Pos-Volt value(mA unit) | 0 ~ 9999 mA |

| Start Add + 5 | Neg-Volt | Neg-Volt value(mA unit) | |

| Start Add + 6 | Pos-High-Curr | Pos-High-Curr value(mA unit) | |

| Start Add + 7 | Neg-High-Curr | Neg-High-Curr value(mA unit) | |

| Start Add + 8 | Pos-Low-Curr | Pos-Low-Curr value(mA unit) | 0 ~ 100 mA |

| Start Add + 9 | Neg-Low-Curr | Neg-Low-Curr value(mA unit) | |

| <Table 2> Data saving address and contents of SET read command | |||

DONGA Hitech Smart RPPS communication driver store the same data in WORD, DWORD, FLOAT memory, but the data format are different.

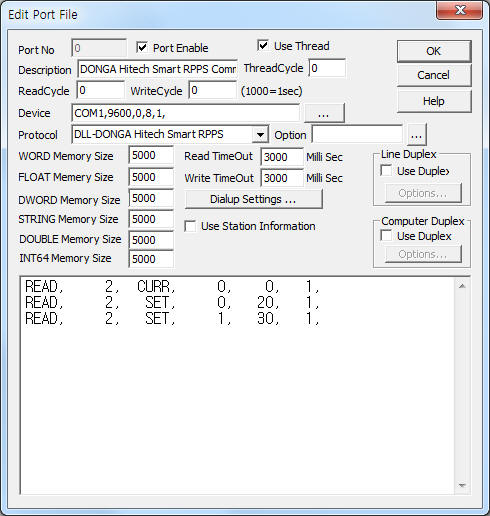

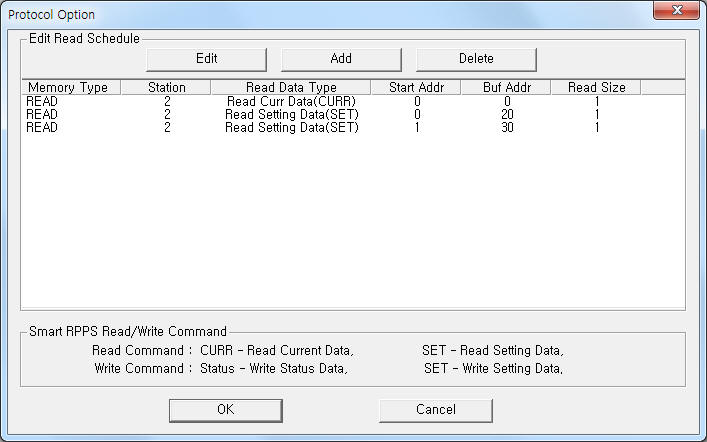

If you click the icon ![]() in protocol option part, you

can see the dialogue box such as <Figure 2>. you can also set read schedule by

using this part.

in protocol option part, you

can see the dialogue box such as <Figure 2>. you can also set read schedule by

using this part.

|

| <Figure 2> Example of DONGA Hitech Smart RPPS communication driverí»s Option dialogue box |

You can set read schedule by using ![]() ,

, ![]() ,

, ![]() button and listbox of <Figure

2>.

button and listbox of <Figure

2>.

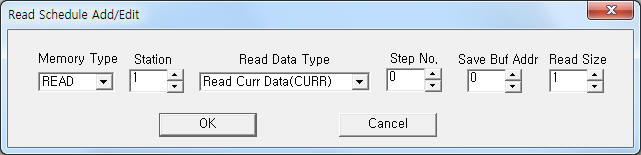

|

| <Figure 3> Example of DONGA Hitech Smart RPPS communication driverí»s read schedule Add/Edit dialogue box |

When you click Add button or Edit button in dialogue box of <Figure 2>, dialogue box of <Figure 3> is shown.

You can write the setting value by using write settings.

Bit Write

Bit write and word write have the same setting parameters except output value( 0 or 1 ).

Word Write

Word write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION Controller station number = 0 ~ 15.

3) ADDRESS Write address.( decimal )

STATUS write command : 0 , 1, 2, 10, 30, 31, ( Refer to <Table 3> )

SET write command : 0 ~ 9 setting type selection. ( Refer to <Table 4> )

4) Extra1 Write command = STATUS - write of register status, SET - write of setting value.

5) Extra2 Step number when SET write command.

<Table 3> is output value and contents of STATUS write command according to address, <Table 4> is output value and contents of SET write command according to address.

| Address | Contents | Output value |

| 0 | ON/Pause of rectifier | ON(1) = ON, OFF(0) = Pause |

| 1 | Setting of operation mode | ON(1) = CC mode, OFF(0) = CV mode |

| 2 | High/Low setting of CC mode | ON(1) = HIGH, OFF(0) = LOW |

| 10 | Setting of end step number | 0 ~ 9 end step number |

| 30 | Ah Reset | ON(1) = Ah Reset, OFF(0) = don't use |

| 31 | Stop | ON(1) = Stop, OFF(0) = don't use |

| <Table 3> Output value and contents of STATUS write command according to address | ||

| Address | Contents | Output value |

| 0 | Setting time of step operation | 0 ~ 999999 (second unit) |

| 1 | Pos-Time | 1 ~ 9999 (ms unit, Pos-Time) |

| 2 | Neg-Time | 0 ~ 9999 (ms unit, Neg-Time) |

| 3 | Off-Time | 0 ~ 9999 (ms unit, Off-Time) |

| 4 | Pos-Volt | 0 ~ 9999 (mA unit, Pos-Volt) |

| 5 | Neg-Volt | 0 ~ 9999 (mA unit, Neg-Volt) |

| 6 | Pos-High-Curr | 0 ~ 9999 (mA unit, Pos-High-Curr) |

| 7 | Neg-High-Curr | 0 ~ 9999 (mA unit, Neg-High-Curr) |

| 8 | Pos-Low-Curr | 0 ~ 100 (mA unit, Pos-Low-Curr) |

| 9 | Neg-Low-Curr | 0 ~ 100 (mA unit, Neg-Low-Curr) |

| <Table 4> Output value and contents of SET write command according to address | ||

Write example 1)

PORT : 0 STATION : 2 ADDRESS : 0000 EXTRA1 : STATUS EXTRA2 : 0

The setting parameter shown above is an example of ON/Pause setting of rectifier. (station number = 2)

Write example 2)

PORT : 0 STATION : 2 ADDRESS : 0001 EXTRA1 : STATUS EXTRA2 : 0

The setting parameter shown above is an example of setting of operation mode(CC or CV mode).

Write example 3)

PORT : 0 STATION : 2 ADDRESS : 0010 EXTRA1 : STATUS EXTRA2 : 0

The setting parameter shown above is an example of setting of end step number(0 ~ 9 end step number).

Write example 4)

PORT : 0 STATION : 2 ADDRESS : 0031 EXTRA1 : STATUS EXTRA2 : 0

The setting parameter shown above is an example of stop(when write output value 1).

Write example 5)

PORT : 0 STATION : 2 ADDRESS : 0000 EXTRA1 : SET EXTRA2 : 0

The setting parameter shown above is an example of setting time of step operation(0 ~ 999999 second).

Write example 6)

PORT : 0 STATION : 2 ADDRESS : 0003 EXTRA1 : SET EXTRA2 : 2

The setting parameter shown above is an example of setting of off-Time(0 ~ 9999ms).

Connection of main power line and communication cable are as follows.

Connection of main power line

Please connect 220 V AC main power to main power input connector such as <Figure 4>.

<Figure 5> shows the appearance of DONGA Hitech Smart RPPS controller.

|

| <Figure 4> Connection example of main power line and communication cable to DONGA Hitech Smart RPPS |

|

| <Figure 5> Appearance of DONGA Hitech Smart RPPS controller |

Connection of RS-422 communication cable

Please connect R+, R-, T+, T- connectot of Smart RPPS and Tx+, Tx-, Rx+, Rx- connector of computer such as <Figure 4>.

Smart RPPS RS-422 connector RS-422 of computer

Rx+ connector----------------------------------- Tx+ connector

Rx- connector----------------------------------- Tx- connector

Tx+ connector----------------------------------- Rx+ connector

Tx- connector----------------------------------- Rx- connector