DASA Motion Controller Communication Driver is the driver to communicate with motion controller of Dasa Tech.in Korea.

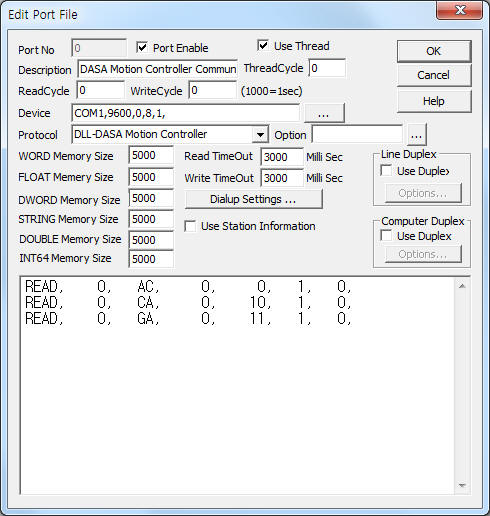

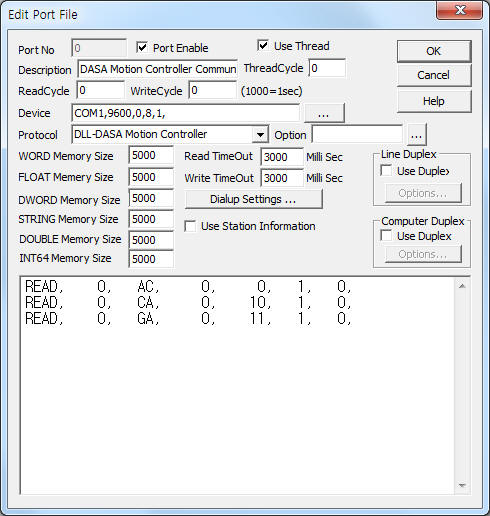

<Figure 1> is read setting example of DASA Motion Controller communication driver.

|

| <Figure 1> Read setting example of DASA Motion Controller communication driver |

Device part of <Figure 1> input Com Port(COM1), Baud Rate(9600), Parity Bit(0), Data Bit(8), Stop Bit(1) respectively.

DASA Motion Controller communication driverí»s read schedule

Read schedule setting parameters are as follows:

1) STATION – Don't care.

2) Read Command – AA : Read of robot status,

AB : Read of error status,

AC : Position read,

CA : Velocity read,

ED : Read of operation line,

EF : Read of operation/setting file,

FC : Whether the file exists,

GA : Read of input card,

GB : Read of output card,

GD : Read of installed card number,

GE : Read of PLC input. ( Refer to <Table 1>, <Table 2> )

3) Read Start Address – Input according to read command. ( Refer to <Table 1> )

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read Size – Fixed to 1.

6) Extra1 – To be readed filename number when 'FC' read command.. ( filename : cmd_%04.txt, %04d = filename number )

Read schedule example)

READ, 0, AC, 0, 0, 1, 0,

READ, 0, CA, 0, 10, 1, 0,

READ, 0, GA, 0, 11, 1, 0,

<Table 1> is read command and contents, start address, extra1 of DASA Motion Controller communication driver.

<Table 2> is store values and contents according to read command.

Read command |

Contents |

Start address |

Extra1 |

AA |

Read of robot status |

Don,t care |

Don,t care |

AB |

Read of error status |

||

AC |

Position read |

type – 0 : Encoder, 1 : Joint, 2 : XYZ |

|

CA |

Velocity read |

Don,t care |

|

ED |

Read of operation line |

||

EF |

Read of operation/setting file |

||

FC |

Whether the file exists |

DISK ID – 0 : Backup RAM, 1 : EEPROM, 2 : FDD |

filename numbe : cmd_%04.txt, %04 =0 ~ 9999 |

GA |

Read of input card, |

0 ~ 99 (input card number) |

Don,t care |

GB |

Read of output card |

0 ~ 99 (output card number) |

|

GD |

Read of installed card number |

Don,t care |

|

GE |

Read of PLC input |

0 ~ 99 (input card number) |

|

| <Table 1> Read command and contents, start address, extra1 of DASA Motion Controller communication driver | |||

Read command |

Store Values |

Contents |

AA |

Start Add + 0 Start Add + 1 |

Data 0 - 3Bit : Error, 2 Bit : Motor Power, 1 Bit : In Position, 0 Bit : Run, Data 1 - 1 Bit : Servo, 0 Bit : Origin Complete, |

AB |

Start Add + 0 ~ n |

Error character display |

AC |

Start Add + 0 ~ n |

Encoder : 10 byte data (0 ~ 999999999), number of axis. Joint : 10 byte float data, number of axis. XYZ : X, Y, Z, A, B, C of axis, 10 byte float data and POSE data. POSE- 2 Bit : right(1)/left(0), 1 Bit : above(1)/below(0), 0 Bit : upper(1)/down(0), |

CA |

Start Add + 0 |

Velocity : 0 ~ 100 |

ED |

Start Add + 0 |

Operating line number : 0 ~ 999 or –1 |

EF |

Start Add + 0 ~ n |

Operating filename number (A : 65) |

FC |

Start Add + 0 |

1 : file exist, 0 : file does not exist |

GA |

Start Add + 0 Start Add + 1 Start Add + 2 ... |

Card number 3 ~ 0 Bit : 1 ~ 4 .... |

GB |

||

GD |

Start Add + 0 Start Add + 1 |

The number of input card (0 ~ 99) The number of output card (0 ~ 99) |

GE |

Start Add + 0 Start Add + 1 Start Add + 2 ... |

Card number 3 ~ 0 Bit : 1 ~ 4 .... |

| <Table 2> Store values and contents according to read command | ||

You can write setting value by using write settings.

Bit Write

Word write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION Refer to <Table 3>.

3) ADDRESS Saving start address for read command.

4) Extra1 Read or write command. Refer to <Table 1>, <Table 3>.

AA : Read of robot status,

AB : Read of error status,

AC : Position read,

BA : Operation starting point,

BB : Specified motion execution, dot position of pre-selected point file,

BC : Specified motion execution of pre-selected data,

BD : Robot move from current position, move count = inputed number,

BE : Jog Move start,

BF : Jog Move Continue,

BG : Jog Move stop,

CA : Velocity read,

CB : Velocity write,

CC : Operation execution,

CD : Operation stop,

CF : Emergency stop,

CG : Error reset,

CH : Motion stop,

CI : Origin Stop,

CJ : System Reboot,

CE : Operation initialize,

DA : Moter Power ON/OFF,

DB : Servo ON/OFF,

DC : To be operated filename setting,

EA : Run Stop Set,

EB : Goto Line,

EC : Break Line setting,

ED : Read of operation line,

EE : Job Run Mode Exit,

EF : Read of operation/setting file,

EG : Break Line clear,

FC : Whether the file exists,

GA : Read of input card,

GB : Read of output card,

GC : Write to output card,

GD : Read of installed card number,

GE : Read of PLC input.

GF : Write to PLC output card.

5) Extra2 To be readed filename number when 'FC'(read), BB, BC, BD, DC command.. ( filename : cmd_%04.txt, %04d = filename number )

<Table 3> is write command and contents, station, start address, extra1, writing value of DASA Motion Controller communication driver.

| Write Command | Contents | STATION | Extra2 | Writing value |

| BA | Operation starting point | Don't care | Don't care | Don't care |

| BB | Specified motion execution, dot position of pre-selected point file | Type

– 0 : Encoder, 1 : Joint, 2 : XYZ |

Command filename number | |

| BC | Specified motion execution of pre-selected data | Data Type 0 : Joint, 1 : ZYZ |

||

| BD | Robot move from current position, move count = inputed number | |||

| BE | Jog Move start | Axis : 0 ~ (number of axis –1) | Direction – 0 : -, 1 : + | Coordinate - 0 : Joint, 1 : ZYZ, 2 : TOOL |

| BF | Jog Move Continue | Don't care | Don't care | Don't care |

| BG | Jog Move stop | |||

| CB | Velocity write | Velocity : 0 ~ 100 | ||

| CC | Operation execution | Don't care | ||

| CD | Operation stop | |||

| CF | Emergency stop | |||

| CG | Error reset | |||

| CH | Motion stop | |||

| CI | Origin Stop | |||

| CJ | System Reboot | |||

| CE | Operation initialize | |||

| DA | Motor Power ON/OFF | 1 : ON, 0 : OFF | ||

| DB | Servo ON/OFF | |||

| DC | To be operated filename setting | Command filename number | Don't care | |

| EA | Run Mode Set | Don't care | Mode – Continuous : 0, line : 1 |

|

| EB | Goto Line | Line number : 0 ~ 999 | ||

| EC | Break Line setting | |||

| EE | Job Run Mode Exit, | Don't care | ||

| EG | Break Line clear | Line number : 0 ~ 999 | ||

| FC | Whether the file exists | Command filename number | Don't care | |

| GC | Write to output card | The number of card : 0 ~ 99 | Point of contact : 0 ~ 99 | Data – HIGH : 1, LOW : 0 |

| GF | Write to PLC output card | |||

| <Table 3> Write command and contents, station, start address, extra1, writing value of DASA Motion Controller communication driver | ||||

Method of cmd_%04d.txt)

a) % 04d = the value of 'Extra2' .

example1) Extra2 = 0, filename : cmd_0000.txt

example2) Extra2 = 1, filename : cmd_0001.txt

b) Input each element separated by a comma( , ),

c) Filename input as characters and other elements input as number.

Word Write

Word write and bit write have the same setting parameters except output value.

Write example 1)

Station:0 Address:0000, Extra1:BE, Extra2:1, writing value = 2.0

The setting parameter shown above is an example of 'Jog Move start' command.

The setting element = 1 axis, + direction, TOOL Coordinate.

Write example 2)

Station:1 Address:0000, Extra1:GC, Extra2:2, writing value = 1.0

The setting parameter shown above is an example of 'Write to output card' command.

The setting element = 1 output card, 2( 3rd ) point of contact, high status output.

Write example 3)

Station:0 Address:0050, Extra1:AC, Extra2: ,

The setting parameter shown above is an example of 'Position read' command.

After write, the readed values(Encoder Position) are saved from 50 WORD memory.