CIMON PLC Seria Communication Driver is the driver to communicate with CIMON PLC of KDT Systems Co., Ltd. in Korea.

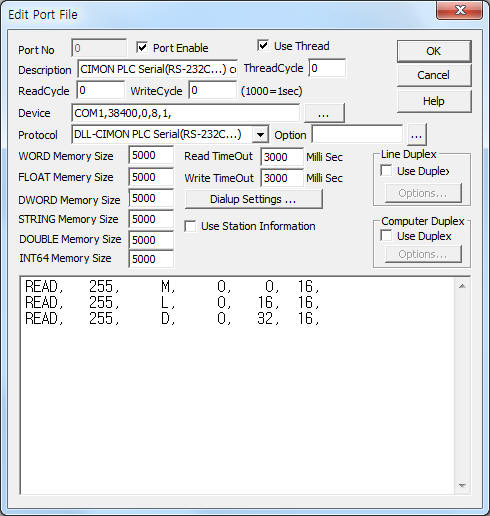

<Figure 1> is read setting example of CIMON PLC Serial(RS-232C, RS-422/485) communication driver.

|

| <Figure 1> Read setting example of CIMON PLC Serial communication driver |

Device part of <Figure 1> input Com Port(COM1), Baud Rate(38400), Parity Bit(0), Data Bit(8), Stop Bit(1) respectively.

CIMON PLC can set station number, baud rate, data bit, stop bit, stop bit by ladder program,

CIMON PLC Serial communication driver¡¯s read schedule

Read schedule setting parameters are as follows:

1) STATION – Station number of PLC = 0 ~ 31 or 255.

2) Read command – Read device type = X, Y, M, L, K, F, T, C, S, D, TC, TS, CC, CS, Z, MON ( Refer to <Table 1>).

3) Read Start Address – Read start address of device.

MON (read of registered monitor data) device type – 0 ~ 15, Frame number.

4) Save start address for Communication Server – Saving start address of Communication Server.

5) Read Size – Read word size (max. 63 word ).

Read schedule example)

READ, 255, M, 0, 0, 16,

READ, 255, L, 0, 16, 16,

READ, 255, D, 0, 32,

16,

Note) Read of registered monitor data( MON ) can read after register to memory by ladder or etc.

Also registered monitor data deleteed when PLC power off.

<Table 1> is device type and data type of CIMON PLC.

| Device | Contents | Description | Data type | Read | Write |

| X | Input | Input of direct data read input | BIT/WORD | WORD unit | Bit(Digital) write, Word(Analog) write(WORD,DWORD)

|

| Y | Output | Output of operation | |||

| M | Internal memory | Internal memory for operation or logic circuits | |||

| L | Link | Data link of upper/the sub PLC/controller | |||

| K | Keep | Equal 'M' memory but keep data when power on/off | |||

| F | Special | Operation status, fault status, card number, etc of PLC | |||

| T | Timer | Timer | BIT only | 10 bit unit | Bit write only |

| C | Counter | Counter | |||

| S | Step control | Relay of step control | WORD only | WORDunit | Word(Analog) write(WORD,DWORD),

Bit write support after WORD reading and bit operation |

| D | Data | Internal data register for data saving | |||

| TC | Current timer | Current timer | |||

| TS | Setting timer | Setting timer | |||

| CC | Current counter | Current counter | |||

| CS | Setting counter | Setting counter | |||

| Z | |||||

| MON | Read of monitor | Read of 0 ~ 15 registered monitor Frame | WORD unit | WORD unit | register of monitor |

| <Table 1> Device type and data type of CIMON PLC | |||||

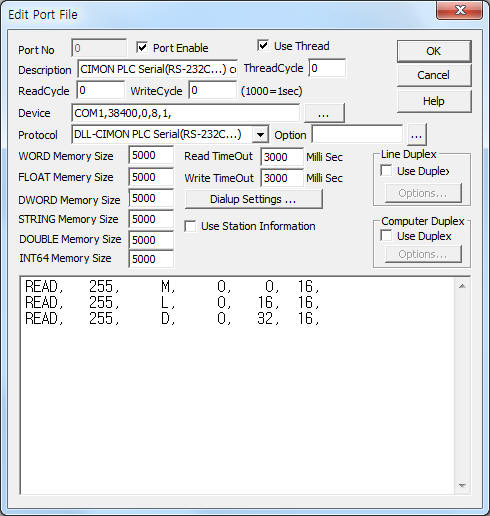

If you click the icon ![]() in

protocol option part, you can see the dialogue box such as <Figure 2>. you can

also set read schedule by using this part.

in

protocol option part, you can see the dialogue box such as <Figure 2>. you can

also set read schedule by using this part.

|

| <Figure 2> Example of CIMON PLC Serial communication driver¡¯s Option dialogue box |

You can set read schedule by using ![]() ,

, ![]() ,

, ![]() button and listbox

of <Figure 2>.

button and listbox

of <Figure 2>.

|

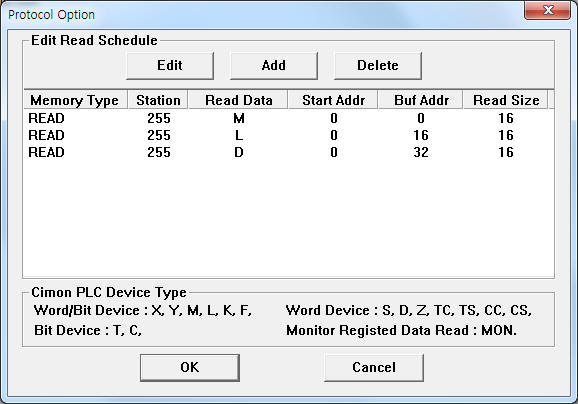

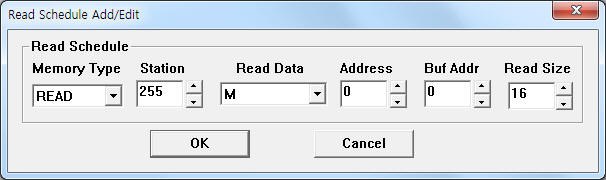

| <Figure 3> Example of CIMON PLC Serial communication driver¡¯s read schedule Add/Edit dialogue box |

When you click Add button or Edit button in dialogue box of <Figure 2>, dialogue box of <Figure 3> is shown.

You can write CIMON PLC Serial by using write settings.

Bit Write

Bit write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION Station number of PLC = 0 ~ 31 or 255.

3) ADDRESS Address of bit write. lower 1 digit( hexadecimal ) = bit position, upper 3 digit( decimal ) = word address.

MON write device type = 4 digit( decimal ) = word address.

4) Extra1 Write device type = X, Y, M, L, K, F, T, C, S, D, TC, TS, CC, CS, Z, MODE, MON_X, ¡¦. (S, D, TC, TS, CC, CS, Z device support after WORD reading and bit operation)

MODE write device type, Address = 0, STOP(OFF), RUN(ON) PLC status command,

Address = 1, PAUSE(OFF), RUN(ON) PLC status command.

monitor register command - MON_X, MON_Y, MON_M, MON_L, MON_K, MON_F, MON_S, MON_D, MON_TC, MON_TS, MON_CC, MON_CS, MON_Z.

5) Extra2 Monitor register command – to be registered monitor WORD count. (output value = Frame No. = 0 ~ 15),

other command - don't care.

Write example 1)

Port : 0 Station : 255 Address : 000F Extra1 : M, EXTRA2 :

The setting parameter shown above is an example of bit write for F bit( 16th bit) of M device at 255 station number.

Write example 2)

Port : 0 Station : 255 Address : 0035 Extra1 : Y, EXTRA2 :

The setting parameter shown above is an example of bit write for 5 bit( 6th bit), 3 word( 4th word) of Y device at 255 station number.

Write example 3)

Port : 0 Station : 255 Address : 012A Extra1 : D, EXTRA2 :

The setting parameter shown above is an example of bit write for A bit( 11th bit), 12 word( 13th word) of D device at 255 station number.

Write example 4)

Port : 0 Station : 255 Address : 0000 Extra1 : MODE, EXTRA2 :

The setting parameter shown above is an example of bit write for STOP(OFF) or RUN(ON ) of PLC Running status at 255 station number.

Word Write

Word write setting parameters are as follows:

1) PORT Port no. (0 ~ 255)

2) STATION Station number of PLC = 0 ~ 31 or 255.

3) ADDRESS Address of word write, 4 digit( hexadecimal ).

4) Extra1 Write device type = X, Y, M, L, K, F, T, C, S, D, TC, TS, CC, CS, Z, MODE, MON_X, ¡¦. ( T, C ard bit write only device )

MODE write device type, Address = 0, STOP(OFF), RUN(ON) PLC status command,

Address = 1, PAUSE(OFF), RUN(ON) PLC status command.

monitor register command - MON_X, MON_Y, MON_M, MON_L, MON_K, MON_F, MON_S, MON_D, MON_TC, MON_TS, MON_CC, MON_CS, MON_Z.

5) Extra2 Normal device type : WORD/DWORD write data size selection of word write. 2 = DWORD, 0 or etc : WORD.

Monitor register command – to be registered monitor WORD count. (output value = Frame No. = 0 ~ 15),

Write example 1)

Port : 0 Station : 255 Address : 0011 Extra1 : M, EXTRA2

The setting parameter shown above is an example of word write for 11 word( 12th word ) of M device at 255 station number.

Write example 2)

Port : 0 Station : 255 Address : 0121 Extra1 : D, EXTRA2 :

The setting parameter shown above is an example of word write for 121 word( 122th word ) of D device at 255 station number.

Write example 3)

Port : 0 Station : 255 Address : 0121 Extra1 : D, EXTRA2 : 2

The setting parameter shown above is an example of double word write for 121 word( low word ) and 122 word( high word ) of D device at 255 station number.

Write example 4)

Port : 0 Station : 255 Address : 0015 Extra1 : MON_D, EXTRA2 : 32

The setting parameter shown above is an example of monitor register for 32 word data from D device 15 word at 255 station number.( output value = 0 ~ 15 frame number )

Connection of communication cable and main power line are as follows.

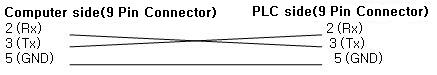

Connection of RS-232C communication cable (simple cable)

Please connect normal RS-232C communication cable to CM1-SC01A RS-232C module of CIMON PLC such as <Figure 4>.

|

| <Figure 4> wiring of simple RS-232C 9pin-9pin cable |

Note) When you select null modem(RS-232C) in the CICON Ladder setting, you should use simplse RS-232C cable such <Figur 4>.

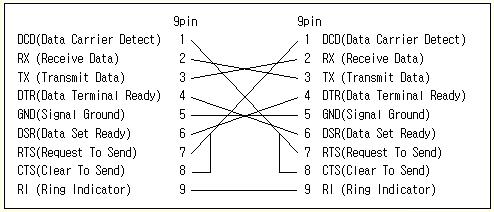

Connection of RS-232C communication cable (full cable)

Please connect full RS-232C communication cable to CM1-SC01A RS-232C module of CIMON PLC such as <Figure 5>.

|

| <Figure 5> wiring of full RS-232C 9pin-9pin cable |

Connection of Half Duplex RS-485 communication cable

Please connect Half Duplex RS-485 communication cable to SDA/RDA(Tx+, Rx+ of computer), SDB/RDB(Tx-, Rx- of computer) of RS-422/485 module of CIMON PLC such as <Figure 6>.

Computer side PLC side

Tx+, Rx+ -------------------------------- SDA, RDA

Tx-, Rx- --------------------------------- SDB, RDB

<Figure 6> wiring of Half Duplex RS-422/485 cable

Connection of RS-422 communication cable (Full Duplex)

Please connect Half Duplex RS-485 communication cable to SDA(Rx+ of computer), SDB(Rx- of computer), RDA(Tx+ of computer), RDB(Tx- of computer) of RS-422/485 module of CIMON PLC such as <Figure 7>.

Compute side PLC side

Tx+ --------------------------------- RDA

Tx- --------------------------------- RDB

Rx+ --------------------------------- SDA

Rx- --------------------------------- SDB

<Figure 7> wiring of Full Duplex RS-422/485 cable

Connection of main power line

Please connect main power line to main power connector, AC220V such as <Figure 8>.

|

| <Figure 8> Connection example of main power line and RS-232C communication cable to CIMON PLC |

Cable connection, protocol type, baud rate, ... setting of CIMON PLC's Serial module are as follows.

1. Connect CIMON PLC loader cable to 'COM' port( COM1, COM2, ... ) of PC.

2. Execute CIMON PLC's loader program, 'CICON'.

3. Link PLC to ¡®Online|Connect¡¯ (or ¡®Online|Connect+Download+Monitor¡¯) menu of 'CICON' program.

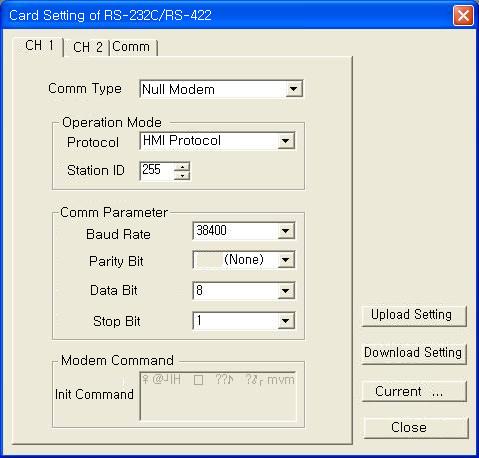

4. Select ¡®Tools|Special card setting..¡¯ menu, then will shows dialog box such as <Figure 9>.

5. Set the card type to RS232C/422 at <Figure 9> and select mounting status(Base, Slot number: CPU next module = 0, ...). When the 'OK' button is pressed, <Figure 10> dialog box appears.

6. Please set Comm Type, Protocol( needed 'HMI Protocol' ) at <Figure 10>.

7. Also set Station ID, Baud Rate, Parity Bit, Data Bit, Stop Bit, ... ( Default : Station ID = 255, baud rate = 38400 BPS, Parity Bit = 0, Data BIt = 8, Stop Bit = 1 )

|

| <Figure 9> Example of special card setting dialog box of CICON program |

|

| <Figure 10> Example of Card Setting of RS232C/422 dialog box of CICON program |