ASM 142 Helium Leak Detector Communication Driver is the driver to communicate with ASM 142 of Adixen Co., Ltd. in France.

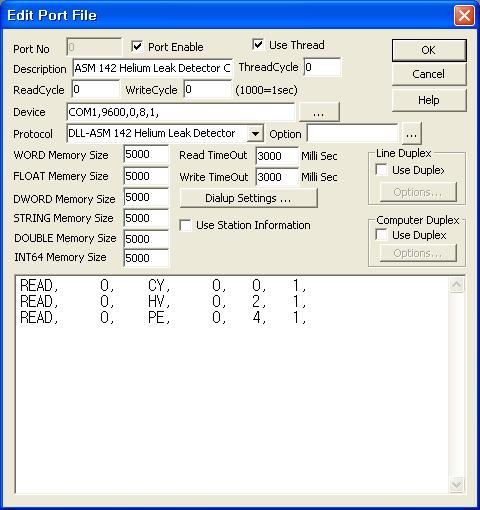

<Figure 1> is read setting example of ASM 142 Helium Leak Detector communication driver.

|

| <Figure 1> Read setting example of ASM 142 Helium Leak Detector communication driver |

<Figure 1> is the screen where Com Port(COM1), Com Baud(9600), Parity Bit(0), Data Bit(8), Stop Bit(1) are input in DEVICE part. Com Baud, Parity Bit, Data Bit, Stop Bit.

Read schedule setting parameters are as follows:

1) STATION – Don't care.

2) Read Command – Command = AA, AC, AC3, ACA, ACH, etc. (Refer to <Table 1>)

3) Read Start Address – Don't care.

4) Save Start Address for Communication Server – saving start address of Communication Server.

5) Read Size – Read Size is fixed with 1.

Read schedule example)

READ, 0, CY, 0, 0, 1,

READ, 0, HV, 0, 2, 1,

READ,

0, PE, 0, 4, 1,

<Table 1> is a description of read commands type and stored values of ASM 142 Helium Leak Detector communication driver.

| Read Command | Content | Stored Values | Remarks |

| AA | Read the Delpollution parameter on Cycle stop | Start Add + 0 : Parameter Value(Float) Start Add + 1 : Enable/Disable |

1 = Enable, 0 = Disable |

| AC | Read of Autocalibration status | Start Add + 0 : autocal On/Off | 1 = On, 0 = Off |

| AC3 | Read of Autocalibration target value | Start Add + 0 : calibration target value | Float/Double type |

| ACA | Read of Autocalibration automatic request parameter | Start Add + 0 : warning type Start Add + 1 : warning cycle number Start Add + 2 : warning time |

warning : 1 = automatic, 0 = non-automatic |

| ACH | Read of leak value for external calibration of Hard vacuum test | Start Add + 0 : leak value |

Float/Double type |

| ACS | Read of leak value for external calibration of Sniffing test | Start Add + 0 : leak value |

Float/Double type |

| AK | Read of whether the use of Discharge protocol | Start Add + 0 : whether the use of discharge protocol | 1 = use, 0 = don't use |

| AZ | Read of Autozero status | Start Add + 0 : autozero status | 1 = On, 0 = Off |

| CA | Read of parameter of Auto Cycle function | Start Add + 0 : auto cycle status(1 = ON, 0 = Off) Start Add + 1 : roughing timer(1 = execution, 0 = non-execution) Start Add + 2 : parameter value 1 Start Add + 3 : parameter value 2 |

Parameter value = WORD type |

| CF | Read of Filament sensitivity coefficient | Start Add + 0 : filament sensitivity coefficient 1 Start Add + 1 : filament sensitivity coefficient 2 |

Float/Double Type |

| CH | Read of Hour counter value | Start Add + 0 : counter value 1 Start Add + 1 : counter value 2 Start Add + 2 : counter value 3 |

Word Type |

| CO | Read of Communication parameter value | Start Add + 0 : communication baud Start Add + 1 : data bit(5,6,7,8 bit) Start Add + 2 : parity bit Start Add + 3 : stop bit(2 = 1 byte, 3 = 1.5 byte, 4 = 2 byte) |

communication baud : 1 = 2400, 2= 4800, 3= 9600, 4= 19200, 5 = 38400 parity bit : 2 = Even, 1 = Odd, 0 = None |

| CY | Read of Current status of Detector | Start Add + 0 : current status value | 6 = Start, 5 = electronic zero calibration, 4 = calibration by user, 3 = calibration by detector, 2 = hard vacuum cycle, 1 = sniffing cycle, 0 = depollution cycle |

| DA | Read of Current date | Start Add + 0 : month Start Add + 1 : day Start Add + 2 : year |

year = two-digit |

| ER | Read of Saved error | Start Add + 0 : error number(Word) Start Add + 1 ~ : error code(Word) |

If there are no errors, the error code is not displayed. |

| FC | Read of RS flow control value | Start Add + 0 : flow control value | 1 = none, 2 = RTS/CTS, 3 = XON/XOFF, 4 = ETX/ACK |

| FE | Read of Internal calibrated leak value | Start Add + 0 : leak value(Float) Start Add + 1 : temperature coefficient(word) Start Add + 2 : aging coefficient(word) Start Add + 3 : year (four-digit) Start Add + 4 : calibration temperature(word) |

|

| FM | Read of Filament status | Start Add + 0 : filament 1 status Start Add + 1 : filament 2 status |

1 = filament ok 0 = filament of burned status |

| GZ | Read of used tracer gas | Start Add + 0 : gas value | gas mass = 2, 3, 4 |

| HV | Read of Hard VAC coefficient | Start Add + 0 : coefficient value(Float) Start Add + 1 : status |

status : 1 = active coefficient, 0 = inactive cofficient |

| IE | Read of Emission voltage | Start Add + 0 : voltage | 1/100 mA Unit |

| IE1 | Read of Filament 1 emission voltage | Start Add + 0 : voltage | 1/100 mA Unit |

| IE2 | Read of Filament 2 emission voltage | Start Add + 0 : voltage | 1/100 mA Unit |

| LE | Read of Modified calibrated helium signal value | Start Add + 0 : helium signal value(Float) Start Add + 1 : status |

status : 1 = unmodified signal, 0 = modified signal |

| LE2 | Read of alibrated helium signal value which is different from current unit | Start Add + 0 : helium signal value | Float/Double type |

| MCC | Read of Cycle counter | Start Add + 0 : current value Start Add + 1 : initial setting value |

Float/Double type |

| MC0 | Read of First Pump counter value | Start Add + 0 : current value Start Add + 1 : initial setting value |

WORD type |

| MC1 | Read of Second Pump counter value | Start Add + 0 : current value Start Add + 1 : initial setting value |

WORD type |

| MD | Read of Software version | Start Add + 0 : software version | Only stored in STRING memory |

| ME | Read of Memo function status | Start Add + 1 : memo function status Start Add + 2 : memo type(1 = timer, 0 = 2 cycle) Start Add + 3 : memo time(minute) Start Add + 4 : memo time(second) Start Add + 5 : memo signal current value(Float) |

memo function : 2 = In progress, 1 = On, 0 = Off |

| P1 | Read of Tthreshold roughing/GL pressure | Start Add + 0 : pressure | Float/Double Type(mbar) |

| P2 | Read of Tthreshold GL/normal presure | Start Add + 0 : pressure | Float/Double Type(mbar) |

| PE | Read of Inlet pressure | Start Add + 0 : pressure | Float/Double Type(mbar) |

| PW | Read of Password | Start Add + 0 : password | Only stored in STRING memory |

| RE | Read of Recent test result | Start Add + 0 : result value | 1 = good, 0 = bad |

| RS | Read of RS-232C mode | Start Add + 0 : mode value | 0 = not used, 1 = Basic mode, 2 = Spreadsheet mode, 3 = Advanced mode |

| S1 | Read of Current test threshold value | Start Add + 0 : threshold value | Float/Double Type |

| S1H | Read of Vacuum test threshold value | Start Add + 0 : threshold value | Float/Double Type |

| S1S | Read of Sniffing test threshold value | Start Add + 0 : threshold value | Float/Double Type |

| SC | Read of Cell status | Start Add + 0 : emission info Start Add + 1 : cell security Start Add + 2 : triode security |

emission info : 1 = On, 0 = Off, cell/triode security : 1 = no security, 0 = security |

| SN | Read of Sniffing coefficient value | Start Add + 0 : coefficient value(Float) Start Add + 1 : status |

status : 1 = activated, 0 = deactivated |

| SO | Read of Sound status | Start Add + 0 : volume(Word) Start Add + 1 : validation |

validation : 1 = validation, 0 = sound inhibited |

| SP | Read of Setting language | Start Add + 0 : setting language | Only stored in STRING memory |

| ST | Read of Detector status value | Start Add + 0 : status(each bit) | Refer to <Table 2> |

| SW | Read of Used filament | Start Add + 0 : used filament value | 1 = filament 1, 2 = filament 2 |

| SY | Read of Voice synthesis status | Start Add + 0 : volume(Word) Start Add + 1 : validation |

validation : 1 = voice synthesis validation, 0 = voice synthesis inhibited |

| T1 | Read of Second pump information | Start Add + 0 : second pump information | 0 = default pump, 1 = rotation pump, 2 = syncro pump, 3 = running-in pump |

| T1M | Read of Additional second pump information | Start Add + 0 : hour counter(Word) Start Add + 1 : pump temperature(Word) |

|

| TE | Read of Temperature status | Start Add + 0 : temperature(Word) Start Add + 1 : status |

status : 1 = probe measure, 0 = pre-adjusted value |

| TI | Read of Current time | Start Add + 0 ~ 2 : current time hour/minute/second | |

| TIA | Read of Recent stop time | Start Add + 0 ~ 2 : stop time hour/minute/second | |

| TIC | Read of Recent autocalibration time | Start Add + 0 ~ 2 : time hour/minute/second | |

| TIM | Read of Recent start time | Start Add + 0 ~ 2 : start time hour/minute/second | |

| TR | Read of Automatic string | Start Add + 0 : modified helium signal(Float) Start Add + 1 : detector status code(Refer to <Table 2>) Start Add + 2 : inlet pressure value(Float) |

|

| UN | Read of Used unit | Start Add + 0 : unit | 1 = mbar.l/s, 2 = Pa.m3/s, 3 = Torr.l/s |

| V1 | Read of Torbo pump speed | Start Add + 0 : speed(Word) Start Add + 1 : status |

speed unit = RPM status : 1 = accurate measurement, 0 = inaccurate measurement |

| VE | Read of spreadsheet mode standard time | Start Add + 0 ~ 2 : standard time hour/minute/second | In case of 00:00:00, standard time = 0.5 second |

| VO | Read of Current accleration voltage | Start Add + 0 : voltage(Word) | |

| VO1 | Read of Filament 1 accleration voltage | Start Add + 0 : voltage(Word) | |

| VO2 | Read of Filament 2 accleration voltage | Start Add + 0 : voltage(Word) | |

| VT | Read of of Existence of inlet vent in end of cycle | Start Add + 0 : status | 1 = inlet vent On, 0 = inlet vent Off |

| WA | Read of Memo warning list | Start Add + 0 : warning number Start Add + 1 ~ : warning code(Word) |

If there are no memo warning list, the warning code is not displayed. |

| ZE | Read of electronic zero value | Start Add + 0 : electronic zero value | Word type |

| ZR | Read of Zoom function status of reject threshold | Start Add + 0 : status | 1 = function On, 0 = function Off |

| <Table 1> Read commands type and stored values of ASM 142 Helium Leak Detector communication driver | |||

<Table 2> is a description of each bit which is stored by 'ST' command.

| Bit | Content | Stored Values |

| bit0 | filament 1/2 | Off = filament 1, On = filament 2 |

| bit 1 | filament On/Off | Off = off, On = on |

| bit 2 | filament out/in | Off = out cycle, On = in cycle |

| bit 3 ~ 4 | 00 = atmosphere/roughing, 01 = GL, 10 = FL, 11 = high sensitivity | |

| bit 5 | sniffing On/Off | Off = vacuum test, On = sniffing test |

| bit 6 | autocalibration Ok/Nok | Off = Nok, On = Ok |

| bit 7 | locked panel locked/opened | Off = locked, On = opened |

| bit 8 | default presence | Off = default, On = no default |

| bit 9 | inlet vent value status | Off = no inlet, On = inlet |

| bit 10 | cycle start available | Off = not available, On = available |

| bit 11 | turbo pump syncro | Off = no syncro, On = syncro |

| bit 12 ~ 13 | - | - |

| bit 14 | siiffer probe clogged | Off = Clogged, On = not Clogged |

| bit 15 | 1 | On |

| <Table 2> Each bit which is loaded by 'ST command | ||

ASM 142 Helium Leak Detector communication driver store the same data in WORD, DWORD, FLOAT, DOUBLE, STRING memory, but the data formats are different.

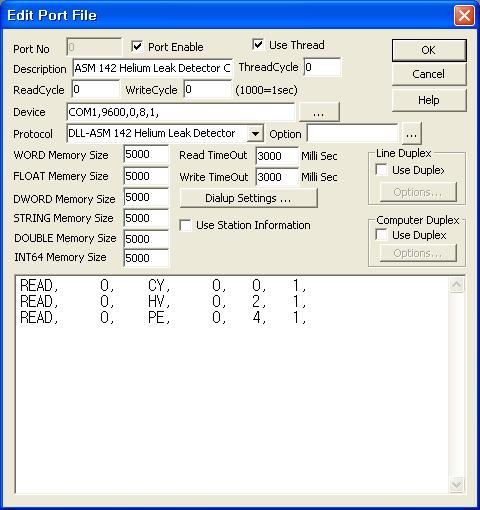

If you click the icon

![]() in protocol option part, you can see the dialogue

box such as <Figure 2>. you can also set read schedule by using this part.

in protocol option part, you can see the dialogue

box such as <Figure 2>. you can also set read schedule by using this part.

|

| <Figure 2> Example of ASM 142 Helium Leak Detector Communication Driver¡¯s Option dialogue box |

You can set read schedule by using

![]() ,

,

![]() ,

,

![]() button and listbox of <Figure 2>.

button and listbox of <Figure 2>.

|

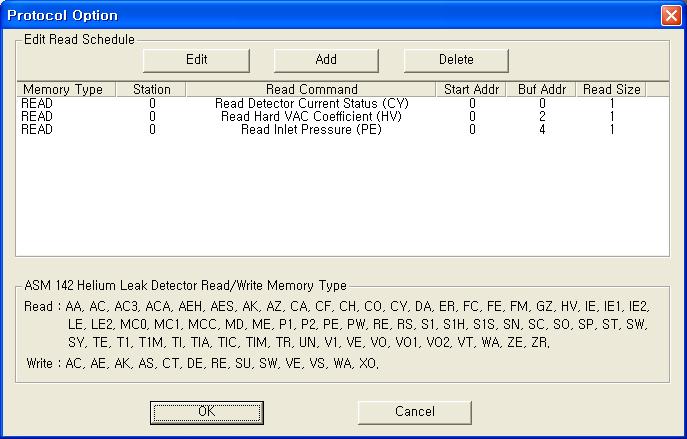

| <Figure 3> Example of ASM 142 Helium Leak Detector communication driver¡¯s read schedule Add/Edit dialogue box |

When you click Add button or Edit button in dialogue box of <Figure 2>, dialogue box of <Figure 3> will be shown.

You can control values of ASM 142 Helium Leak Detector by using write commands.

Bit write

Bit write and word write have the same setting parameters except output value(0 or 1).

Word write

Word write setting parameters are as follows:

1) PORT : Port no. (0 ~ 255)

2) STATION : Don't care.

3) ADDRESS : Don't care

4) EXTRA 1 : AC, AE, AK, AS, CT, DE, RE, SU, SW, VE, VS, WA, XO. (Refer to <Table 3>)

5) EXTRA 2 : Don't care.

<Table 3> is a description of write commands and contents of ASM 142 Helium Leak Detector communication driver.

| Command | Contents |

| AC | Autocalibration Starting |

| AE | External calibration coefficient Calculation and Execution |

| AK | Long commands discharge protocol Disable |

| AS | Internal autocalibration Abort |

| CT | Hardware RTS/CTS protocol Control |

| DE | Default valuePC software reset Reinitialization |

| RE | Saved defaults Reset |

| SU | Advanced mode Selection |

| SW | Filament Exchange |

| VE | Spreadsheet mode Selection |

| VS | Basic mode Selection |

| WA | Warning Reset |

| XO | XON/XOFF software protocol |

| <Table 3> Write commands for ASM 142 Helium Leak Detector communication driver | |

Write example 1)

PORT:0, station:1, ADDRESS:0000, Extra1:SU, Extra : 0

The setting parameter shown above is an example of word write for Advanced mode Selection of ASM 142 Helium Leak Detector connected with 0 port.

Write example 2)

PORT:0, station:0, ADDRESS:0000, Extra1:WA, Extra : 0

The setting parameter shown above is an example of word write to reset Warning of ASM 142 Helium Leak Detector connected with 0 port.

Block write

ASM 142 Helium Leak Detector communication driver doesn¡¯t support ¡®Block write¡¯.

You can connect communication cable between ASM 142 Helium Leak Detector and computer in the following ways.

RS-232C Communication Cable Connection

Connect RS-232C serial socket of ASM 142 Helium Leak Detector and RS-232C cable.

<Figure 4> shows the appearance of ASM 142 Helium Leak Detector.

|

| <Figure 4> Appearance of ASM 142 Helium Leak Detector |